Testing device for pipeline cathodic protection potential test piece and preparation method of testing device

A cathodic protection and testing device technology, applied in the field of pipeline protection, can solve the problems of different leak point shapes, polarization potential errors, etc., and achieve the effects of quick and convenient disconnection operation, ensuring accuracy, and protecting test leads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

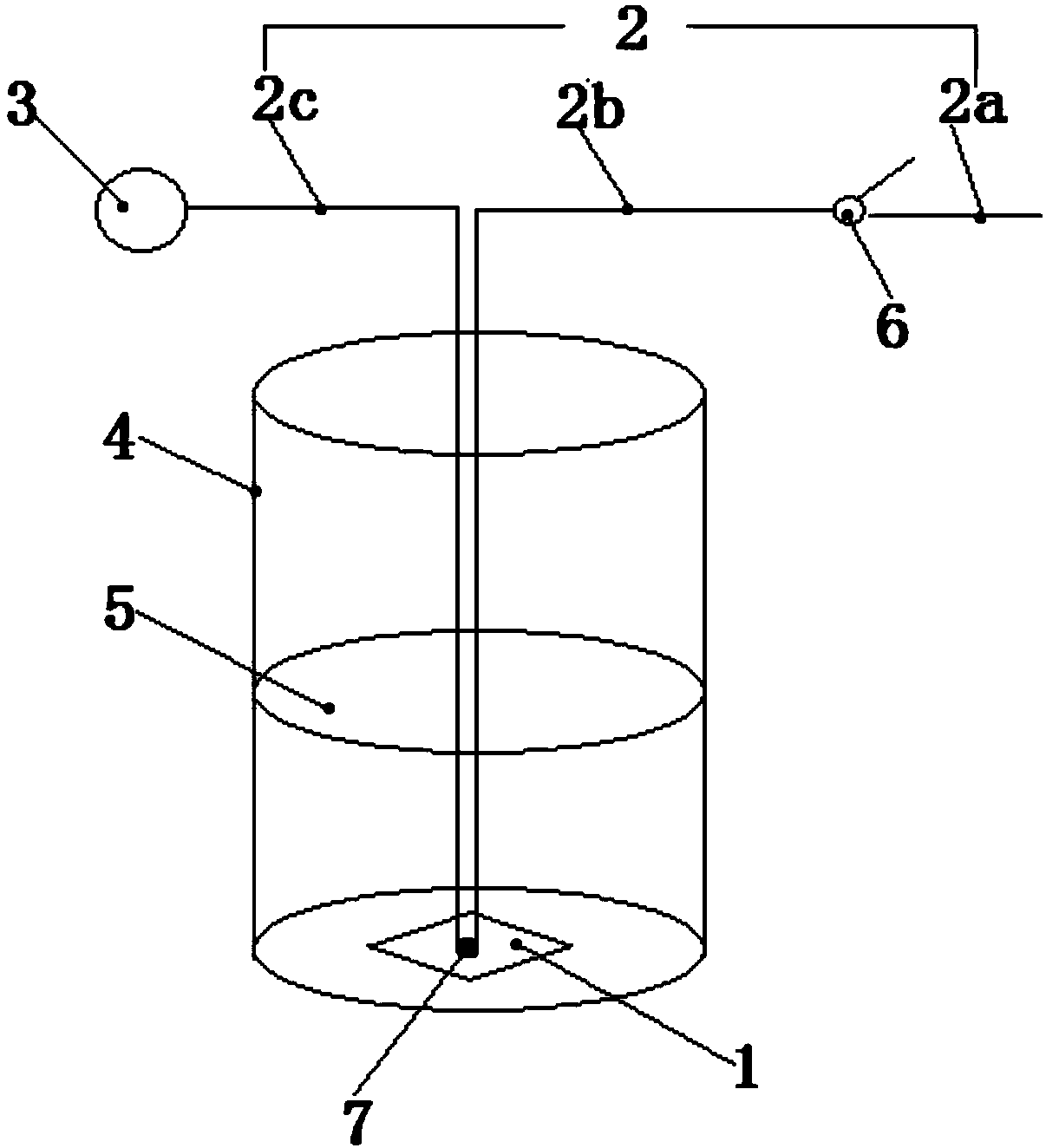

[0065] In a second aspect, an embodiment of the present invention provides a method for preparing a pipeline cathodic protection potential inspection sheet test device, the preparation method comprising the following steps:

[0066] Step (1), connecting the second test lead 2b and the third test lead 2c to the upper surface of the metal test strip 1 respectively.

[0067] Step (2), the lower surface of the metal test piece 1 is bonded on the workbench, then the lower end of the protective shell 4 is bonded on the workbench, and the metal test piece 1 is positioned in the protective shell 4, while the second The test lead 2b and the third test lead 2c are drawn out from the protective case 4 .

[0068] Step (3), pour the liquid insulating material into the protective shell 4 , wrap the metal test piece 1 in the liquid insulating material, and then solidify the liquid insulating material to form the insulator 5 in the protective shell 4 .

[0069] Step (4), remove the protectiv...

Embodiment 1

[0086] This embodiment provides a pipeline cathodic protection potential inspection sheet testing device, the preparation steps of which are as follows:

[0087] 1) Cut the X60 steel into a metal test piece 1 with a specification of 30mm×30mm×3mm. The surface of the metal test piece 1 is required to be flat, rust-free, and oil-free.

[0088] 2) Use brazing equipment to connect the two wires with a cross-sectional area of 2.5mm 2 , the length is respectively the annealed copper wire of 3m and the annealed copper wire of 1.5m respectively as the second test wire 2b and the third test wire 2c, and one end of the two is respectively welded on the surface of the metal test piece 1, forming brazing Point 7.

[0089] 3) Cut the Φ50mm PVC hollow pipe with a wall thickness of 2mm into a PVC hollow pipe with a length of 50mm as the protective shell 4, then polish the lower end of the protective shell 4 to be smooth with 800# sandpaper, and process the upper end until it is smooth and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com