Fabric dehydration device for textile machine

A technology of dehydration device and textile machinery, which is applied in the direction of processing textile material equipment configuration, processing textile material containers, processing textile material drums, etc. It can solve the problems of complex process steps and equipment, low dehydration efficiency of extrusion rollers, and cloth wear. Achieve the effects of improving dehydration effect, improving stability and reliability, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

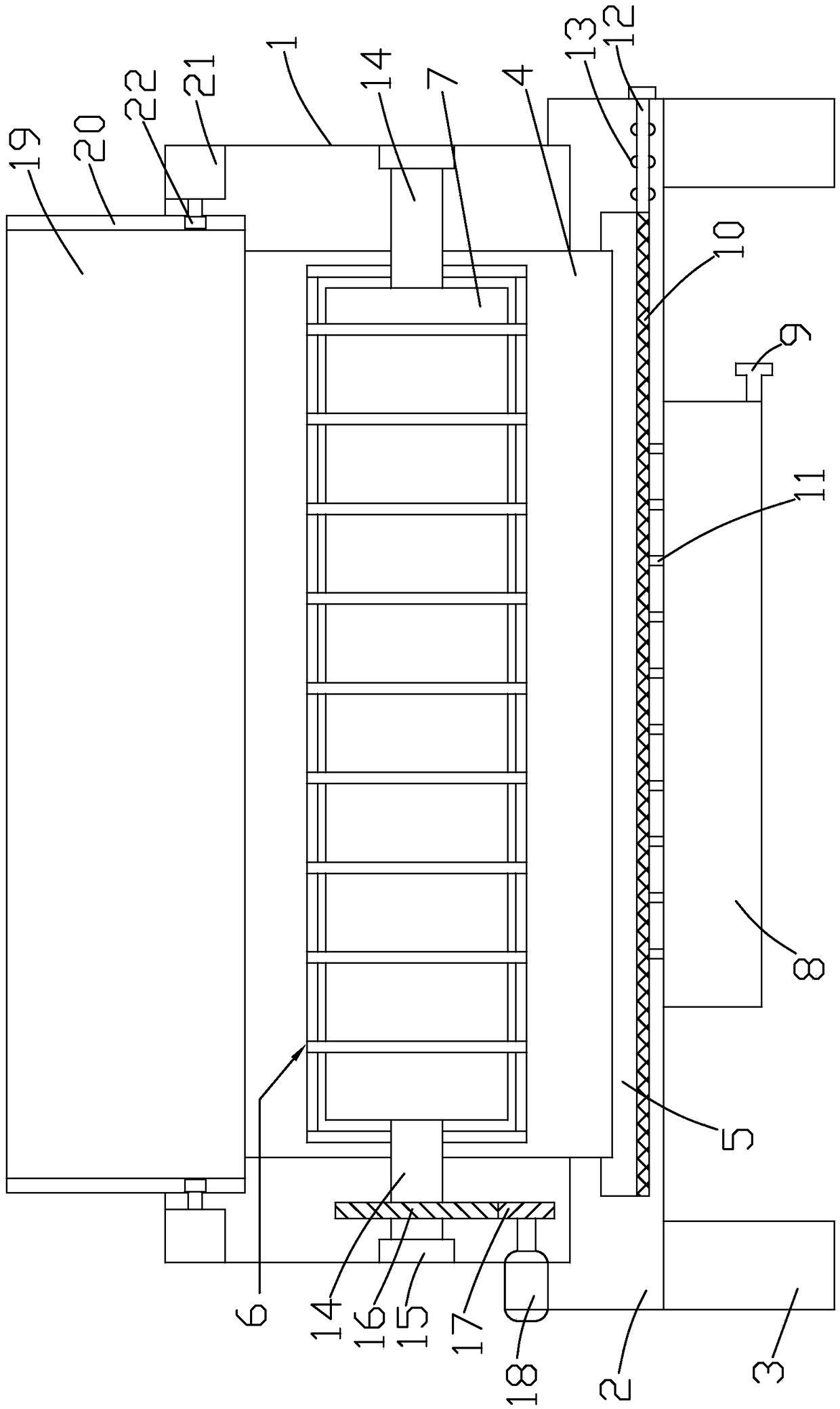

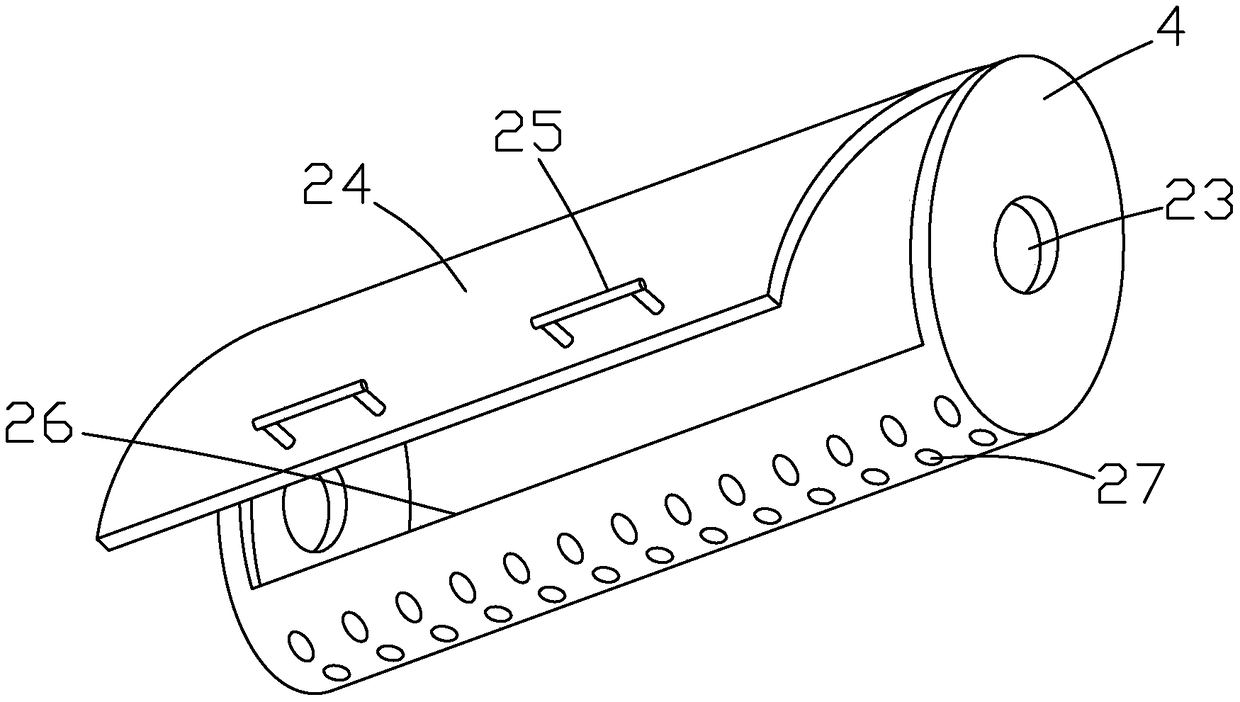

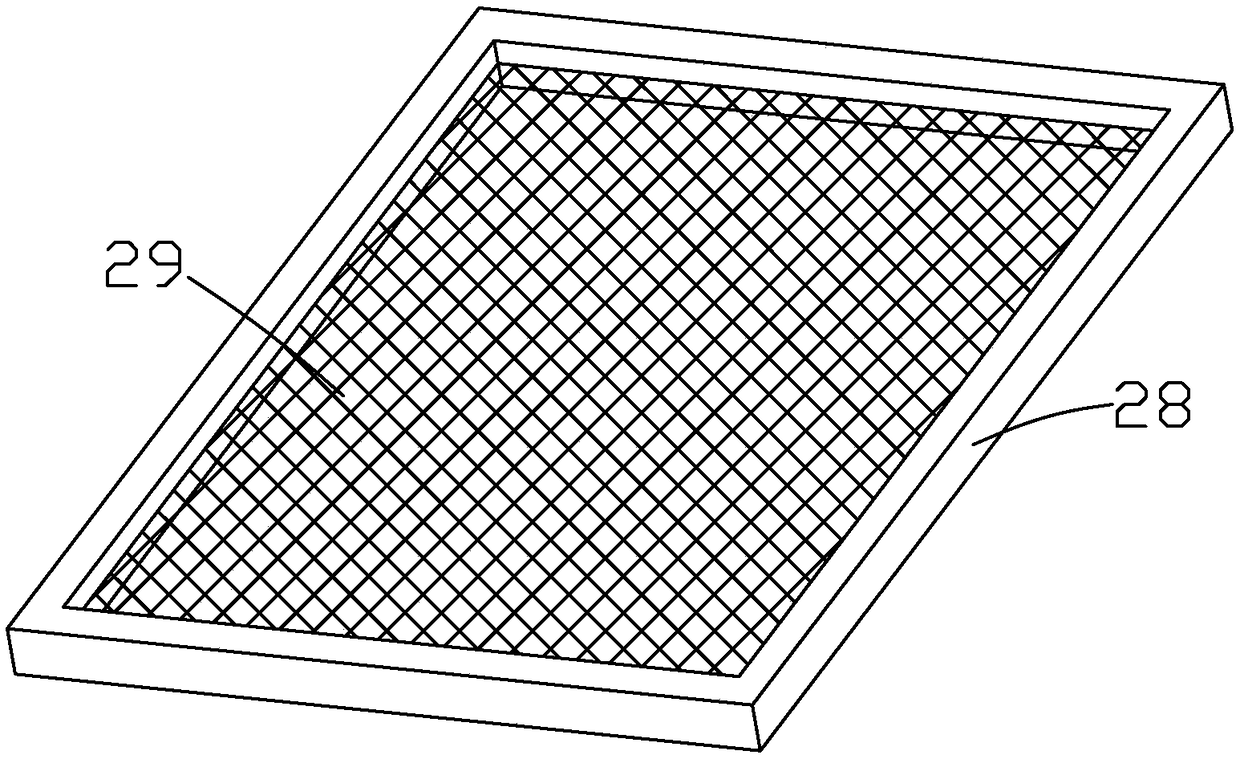

[0031] Such as Figure 1 to Figure 5 As shown, it is a fabric dehydrating device for textile machinery according to the present invention, which includes a box body 1 and a base 2, the box body 1 is fixedly connected to the top surface of the base 2, and the bottom of the base 2 is provided with a supporting foot 3 , the box 1 is provided with a cylinder 4, the left and right ends of the cylinder 4 are provided with limit holes 23, the transmission roller 14 matches the limit holes 23, and the outer circumference of the cylinder 4 is provided with a cloth inlet and outlet Slot 26, the cloth in and out groove 26 is rotatably connected with an arc door 24, the arc door 24 is provided with a handle 25, the design of the limit hole 23 has improved the stability and reliability of the transmission roller 14 when it works, and the cloth in and out of the groove 26 It is convenient for the installation and disassembly of the cloth roller 7, the arc door 24 can play a protective role,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com