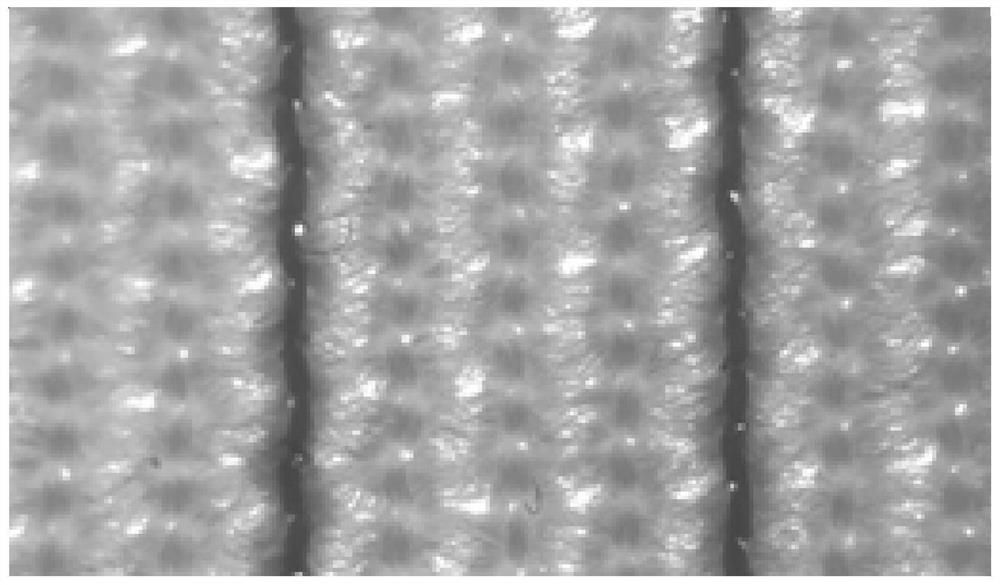

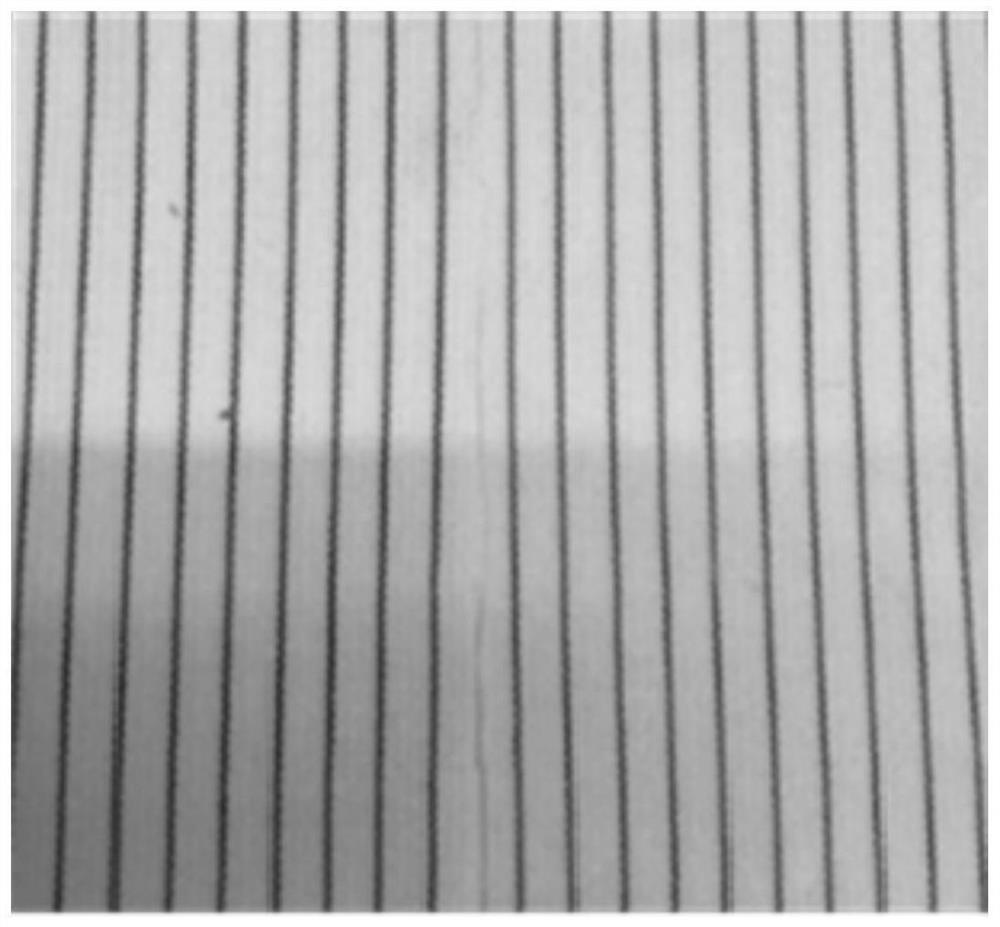

A kind of polyester warp-knitted striped fabric and production method thereof

A technology for polyester and fabrics, which is applied in warp knitting, dyeing, and equipment configuration for processing textile materials. It can solve the problems of cumbersome and complicated preparation processes, poor wrinkle resistance, and poor stability of fabrics, and achieve uniform color and penetration of fabrics. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Select the knitting equipment: Coryte warp knitting machine, the machine size is 28 needles / 25.4mm, the machine width is 186", the bar book is 3bars, and the machine speed is 1200r / min;

[0065] (2) Set the machine parameters: the threading method of the GB1 is to thread three threads and one empty thread, the lapping number is 1-0 / 0-1 / / , the let-off amount is 1010mm / rack, and the number of threads is 420 root, the number of pan heads is 4;

[0066] The yarn threading method of GB2 is to wear one empty three racks, the number of lap yarns is 1-0 / 0-1 / / , the let-off amount is 1000mm / rack, the number of threaded yarns is 140, and the number of pan heads is 4 indivual;

[0067] The threading method of GB3 is full threading, the number of lap yarns is 1-0 / 3-4 / / , the let-off amount is 2222mm / rack, the number of threads is 560, and the number of pan heads is 4;

[0068] (3) Making blanks: 5.6tex / 36f PET FDY (GB1), 5.6tex24f CDP FDY (GB2) and 5.6tex / 36f PET DTY (GB3) are ...

Embodiment 2

[0084](1) Select the knitting equipment: Coryte warp knitting machine, the machine size is 28 needles / 25.4mm, the machine width is 186", the bar book is 3bars, and the machine speed is 1100r / min;

[0085] (2) Set the machine parameters: the threading method of the GB1 is to thread three threads and one empty thread, the lapping number is 1-0 / 0-1 / / , the let-off amount is 1000mm / rack, and the number of threads is 420 root, the number of pan heads is 4;

[0086] The yarn threading method of GB2 is to wear one empty three racks, the number of lap yarns is 1-0 / 0-1 / / , the let-off amount is 1000mm / rack, the number of threaded yarns is 140, and the number of pan heads is 4 indivual;

[0087] The yarn threading method of GB3 is full threading, the number of laying yarns is 1-0 / 3-4 / / , the let-off amount is 2100mm / rack, the number of threading yarns is 560, and the number of pan heads is 4;

[0088] (3) Making blanks: 5.6tex / 36f PET FDY (GB1), 5.6tex24f CDP FDY (GB2) and 5.6tex / 36f PET...

Embodiment 3

[0104] (1) Select the knitting equipment: Coryte warp knitting machine, the machine size is 28 needles / 25.4mm, the machine width is 186", the bar book is 3bars, and the machine speed is 1300r / min;

[0105] (2) Set up the machine parameters: the threading method of the GB1 is to wear three empty ones, the lapping number is 1-0 / 0-1 / / , the let-off amount is 1050mm / rack, and the threading number is 420 root, the number of pan heads is 4;

[0106] The yarn threading method of GB2 is to wear one empty three racks, the number of lap yarns is 1-0 / 0-1 / / , the let-off amount is 1060mm / rack, the number of threaded yarns is 140, and the number of pan heads is 4 indivual;

[0107] The yarn threading method of GB3 is full threading, the number of lap yarns is 1-0 / 3-4 / / , the let-off amount is 2300mm / rack, the number of threading yarns is 560, and the number of pan heads is 4;

[0108] (3) Making blanks: 5.6tex / 36f PET FDY (GB1), 5.6tex24f CDP FDY (GB2) and 5.6tex / 36f PET DTY (GB3) are used ...

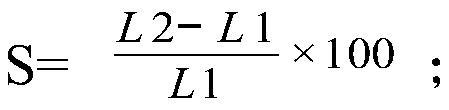

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com