A control method and control device for anti-overflow of asphalt station and asphalt station

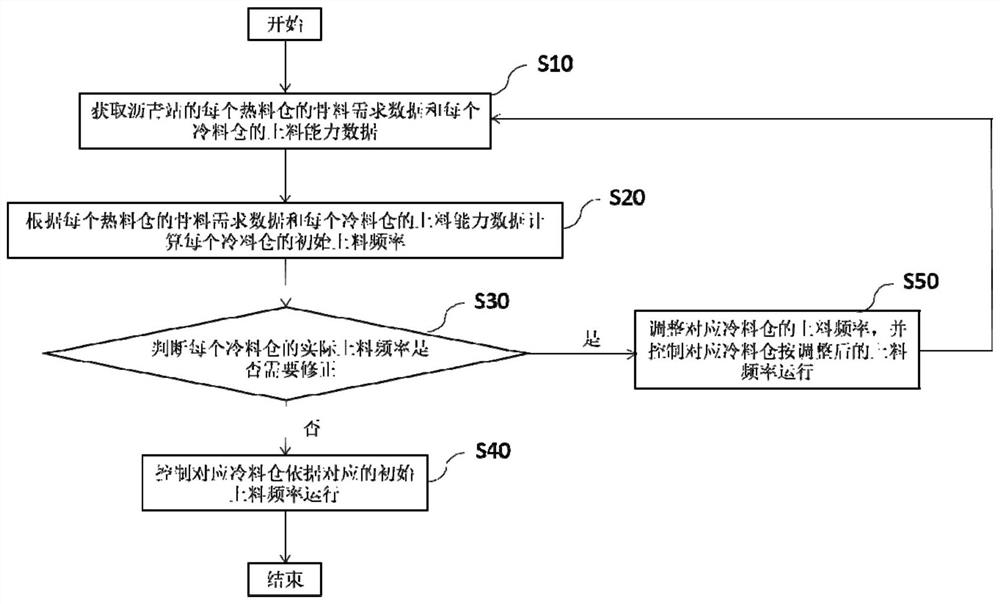

A control method and technology of asphalt plant, applied in the field of asphalt plant, can solve the problems of waste of aggregate, poor matching of feeding speed of cold silo, overflow or equal material, etc., so as to avoid the effect of overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

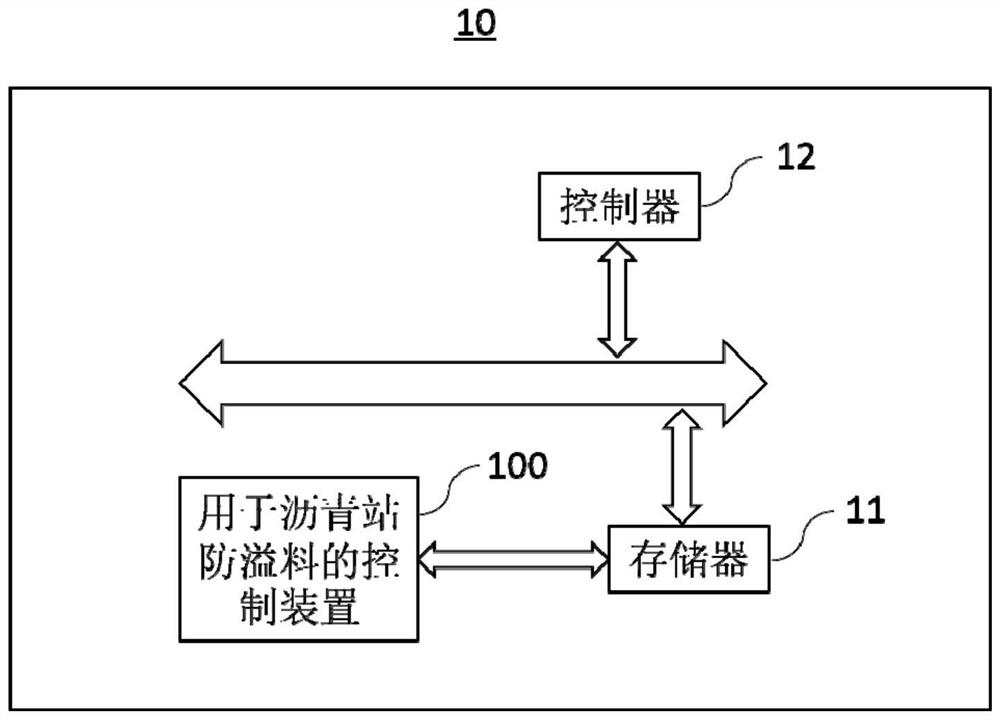

[0046] see figure 1 , figure 1 Shown is a schematic block diagram of the structure of the asphalt plant 10 corresponding to the control method and control device for anti-overflow of asphalt plant provided by the embodiment of the present invention. The control method for anti-overflow in an asphalt station and the control device 100 for anti-overflow in an asphalt station provided in this embodiment are applied to an asphalt station 10 . The asphalt station 10 is mainly used for batch production of asphalt materials such as asphalt mixture, modified asphalt mixture and colored asphalt mixture, and is an important engineering equipment capable of quickly obtaining asphalt materials. The asphalt plant 10 includes a memory 11 , a controller 12 and a control device 100 for anti-spillage of the asphalt plant. The control method and control device for anti-splashing in asphalt stations can correct the actual feeding frequency through the production cycle, formula ratio and feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com