Odour protection aluminum frame wood-plastic plate

An anti-odor, aluminum frame technology, applied in the fields of formwork/formwork components, on-site preparation of building components, formwork/formwork/work frame connectors, etc., can solve the problem of poor installation efficiency, poor overall stability, and lack of Anti-odor function and other issues, to achieve the effect of good effect, improved sealing, simple and convenient splicing operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

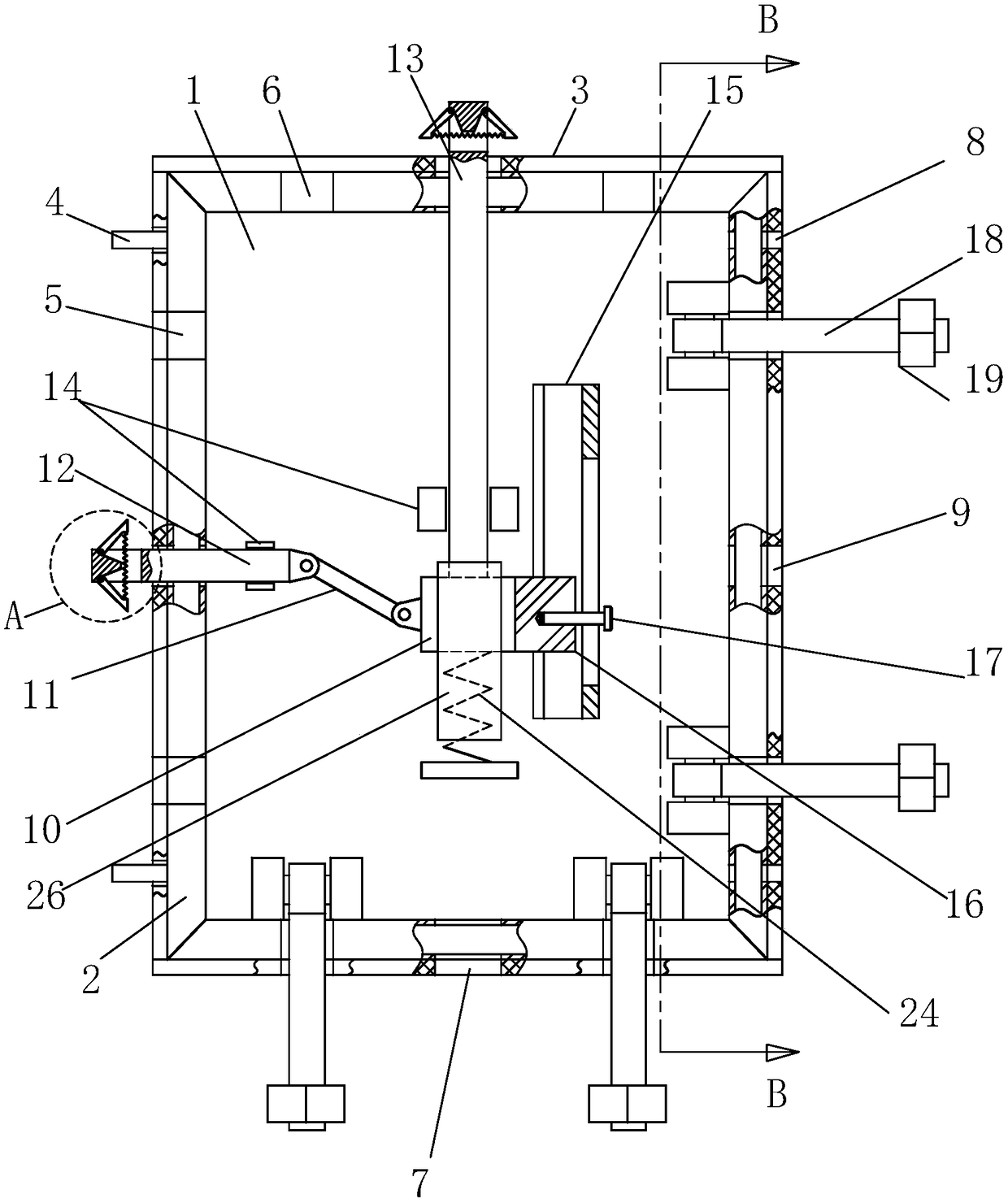

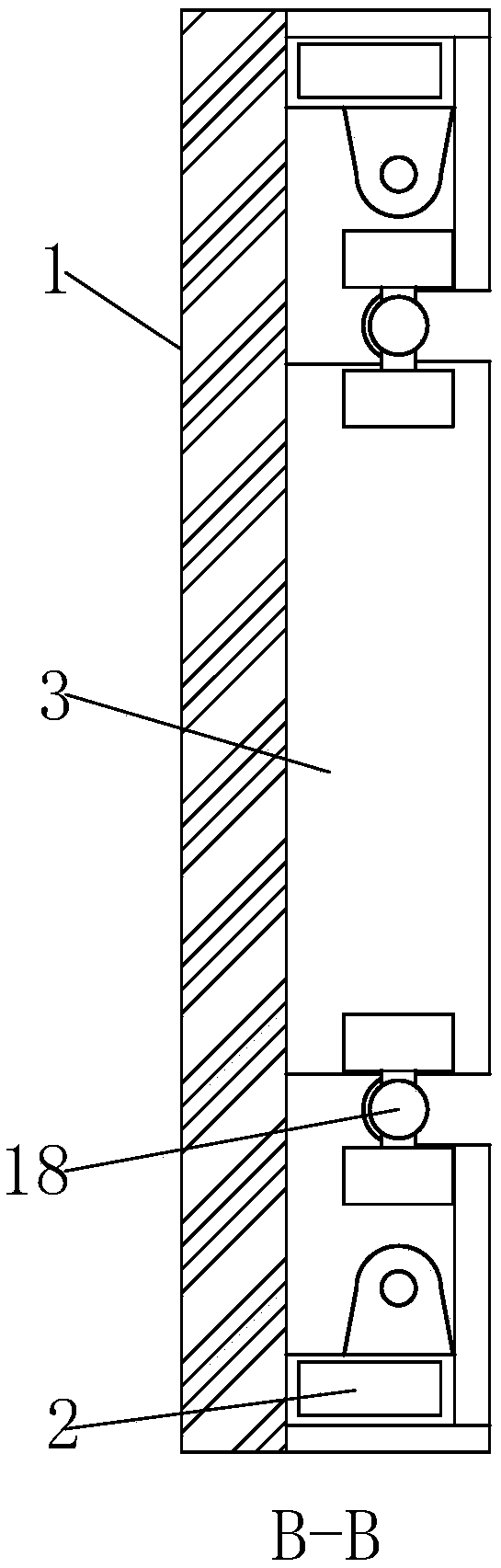

[0039] see Figure 1-6 , the present invention provides a technical solution:

[0040]An anti-odor aluminum-frame wood-plastic board, comprising a board surface 1 and an aluminum frame 2 arranged around the board surface 1; the side of the aluminum frame 2 is provided with a first through hole 7 and a third through hole 9, so The outer surface of the aluminum frame 2 is wrapped with a rubber layer 3 for sealing, and the sealing rubber layer 3 is used to realize seamless compression between adjacent aluminum frames 2, which can effectively prevent cement and odor from spilling and spreading; the board surface 1 The middle part of the support block 10 is provided with; the left side of the support block 10 is hinged with a connecting rod 11; the left end of the connecting rod 11 is hinged with a side slide bar 12 passing through the third through hole 9; The upper side is provided with a vertical slide bar 13 passing through the first through hole 7, the lower end surface of th...

Embodiment 2

[0047] On the basis that other technical solutions of embodiment 1 remain unchanged, this embodiment adopts the following technical solutions:

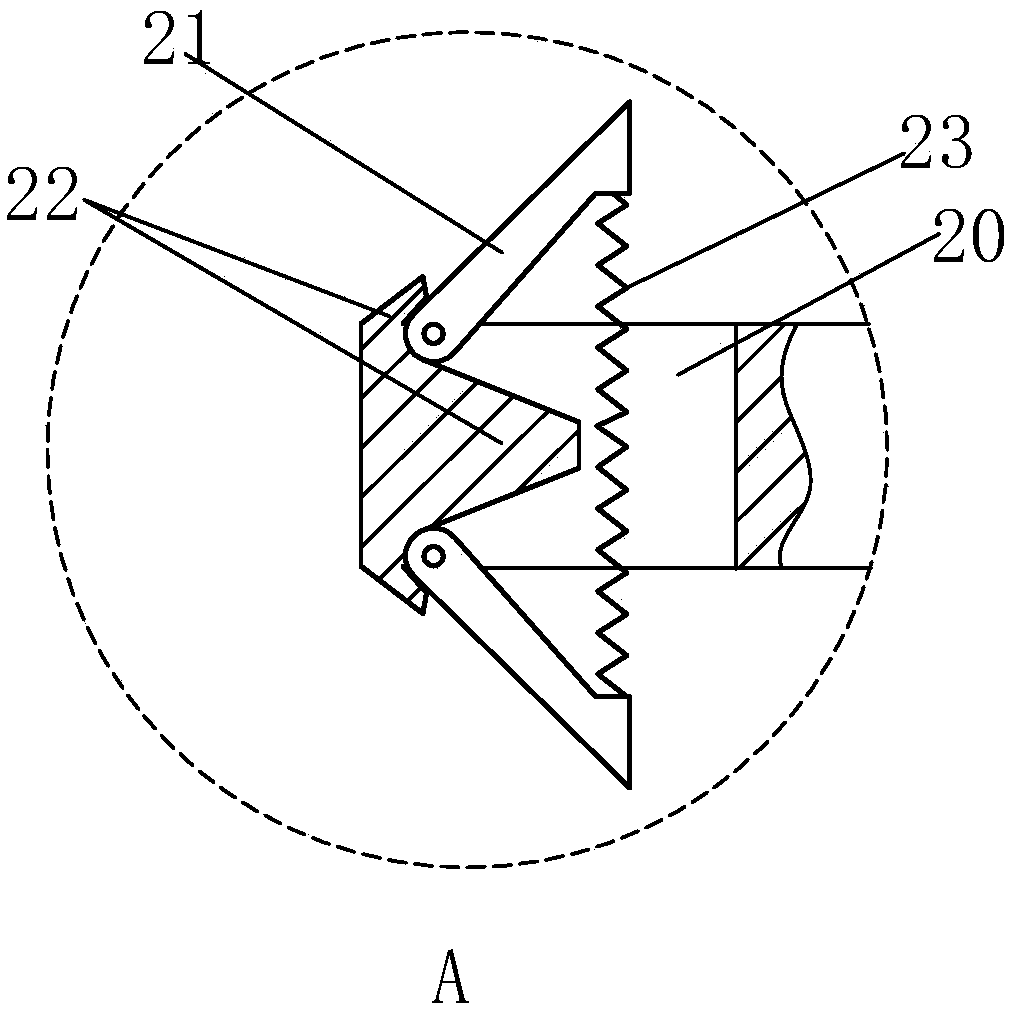

[0048] The thread profile of the threaded push rod 26 is wavy; the lower end of the threaded push rod 26 is provided with a track perpendicular to the board surface 1, and the threaded push rod 26 can move to the side near the operator along the track, and then Break away from the cooperation with the thread groove 25; when in use, the support block 10 is pushed upwards, and after the barb structure passes through the side of the adjacent aluminum frame 2, the support of the threaded push rod 26 to the support block 10 is released, and the support block 10 is reduced Under the support of the shock spring 24, it is reset downwards, and the fastening force of the tensioning claws 21 is tightened to realize the fast and tight splicing of the aluminum frame 2 .

[0049] By setting the wavy thread profile, it is possible to alleviate the h...

Embodiment 3

[0051] On the basis that other technical solutions of embodiment 1 remain unchanged, this embodiment adopts the following technical solutions:

[0052] The threaded push rod 26 is a hollow structure, and the surface of the threaded push rod 26 is provided with a toothed hole 27 penetrating to the hollow structure; a number of toothed rods 28 are interspersed radially in the toothed hole 27; The ejector rod 29 is interspersed; the ejector rod 29 can be penetrated into the hollow structure to eject the toothed rod 28 out of the tooth hole 27, and the outer ends of the plurality of toothed rods 28 are spliced with each other to form a wave-shaped thread structure. The rod 29 is located inside the threaded push rod 26 to ensure that the outer end profile of the gear rod 28 arranged around the ejector rod 29 forms a threaded structure, thereby pushing the support block 10 upwards. After the barb structure passes through the side of the adjacent aluminum frame 2, Pull out the ejec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap