Intelligent pumping unit monitoring system

A technology of monitoring system and pumping unit, which is applied in the direction of mining fluid, measurement, instruments, etc., can solve the problems that cannot meet the monitoring needs of a large number of operating points, and achieve the effect of great promotion value, cost saving and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

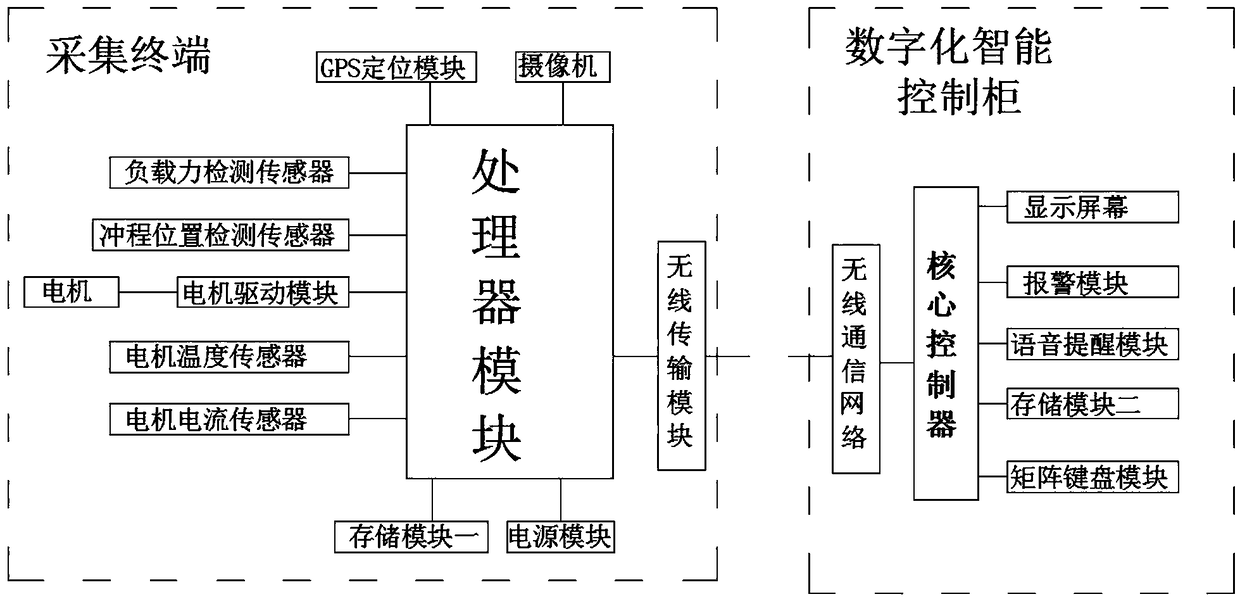

[0029] Such as figure 1 As shown, an intelligent pumping unit monitoring system includes a digital intelligent control cabinet located in the monitoring center and collection terminals located in each operating point;

[0030] The acquisition terminal includes a camera, a load force detection sensor, a stroke position detection sensor, a motor drive module, a motor temperature sensor, a motor current sensor, a power supply module and a wireless transmission module;

[0031] The camera is installed at the operating point for real-time collection of image data at the wellhead and image data of the pumping unit working process, and sends the collected image data to the processor module in real time;

[0032] The load force detection sensor is used to detect the change of the load, and send the detected pressure change data to the processor module in real time;

[0033] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com