Bevel gear transmission pipeline robot

A pipeline robot and bevel tooth technology, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of high sealing risk of the main structure of the robot, no industrial computer for pipeline robots, and inconvenient operation, etc., and achieve good driving effect and large torque , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the purpose and technical solution of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

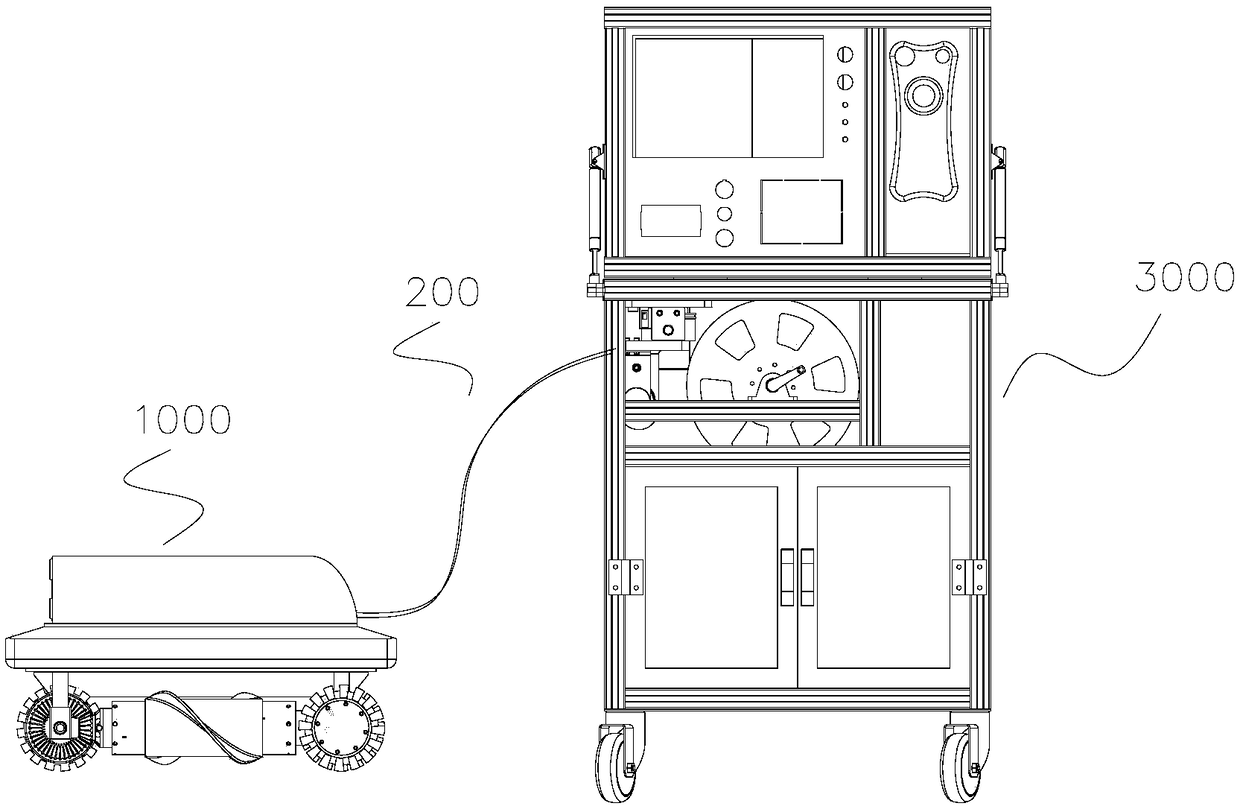

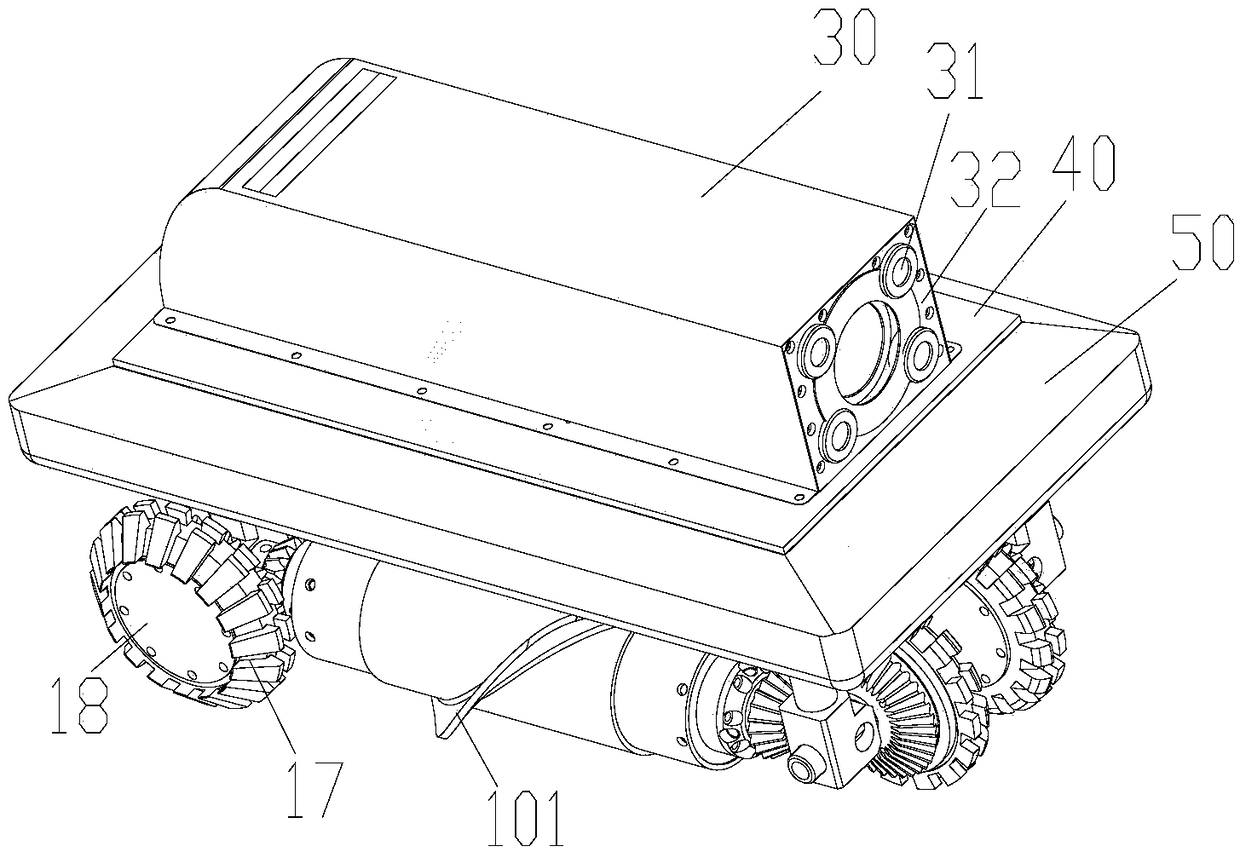

[0081] Such as Figure 1-22 As shown, a pipeline robot with bevel gear transmission includes an industrial computer 3000 and a main structure 1000 .

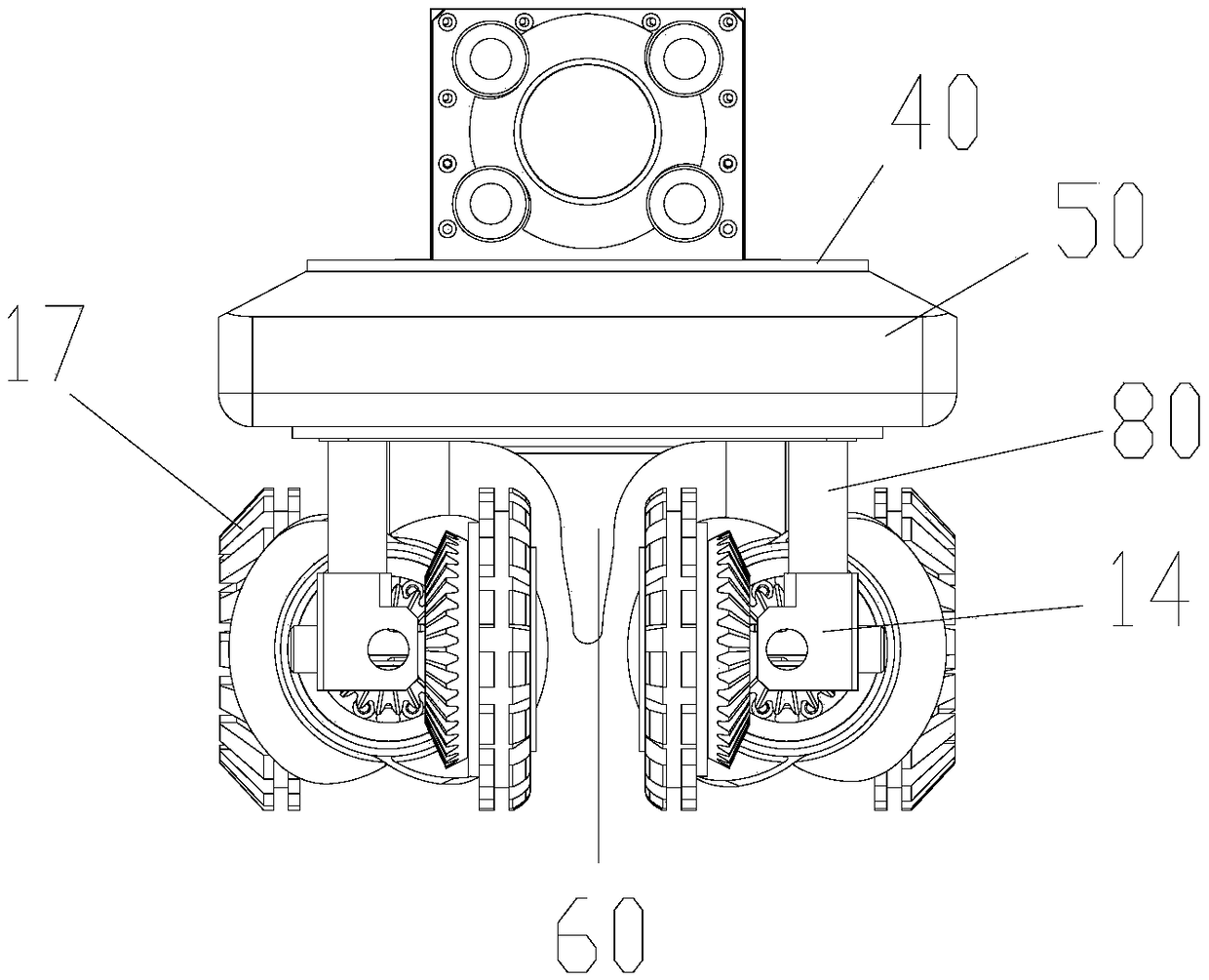

[0082] The main structure includes a support plate 40 , two driving devices rotatably disposed on the support plate, and a first controller fixedly disposed on the support plate 40 . Each driving device comprises a driving roller and two driving rollers arranged at the two ends of the driving roller; each driving roller comprises a first bevel gear 10, a second bevel gear 16, a first connecting piece 14 and a roller, the first bevel gear 10 One end protrudes outward along the axial direction to form a boss 1001, and the center of the boss 1001 is provided with a first through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com