An energy-saving and environment-friendly dryer

An energy-saving and environment-friendly dryer technology, which is applied in the field of dryers, can solve the problems of not being able to make full use of the drying tube for hot air drying, and the energy-saving reduction of the dryer, so as to improve the drying effect, increase the drying time, and reduce the flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

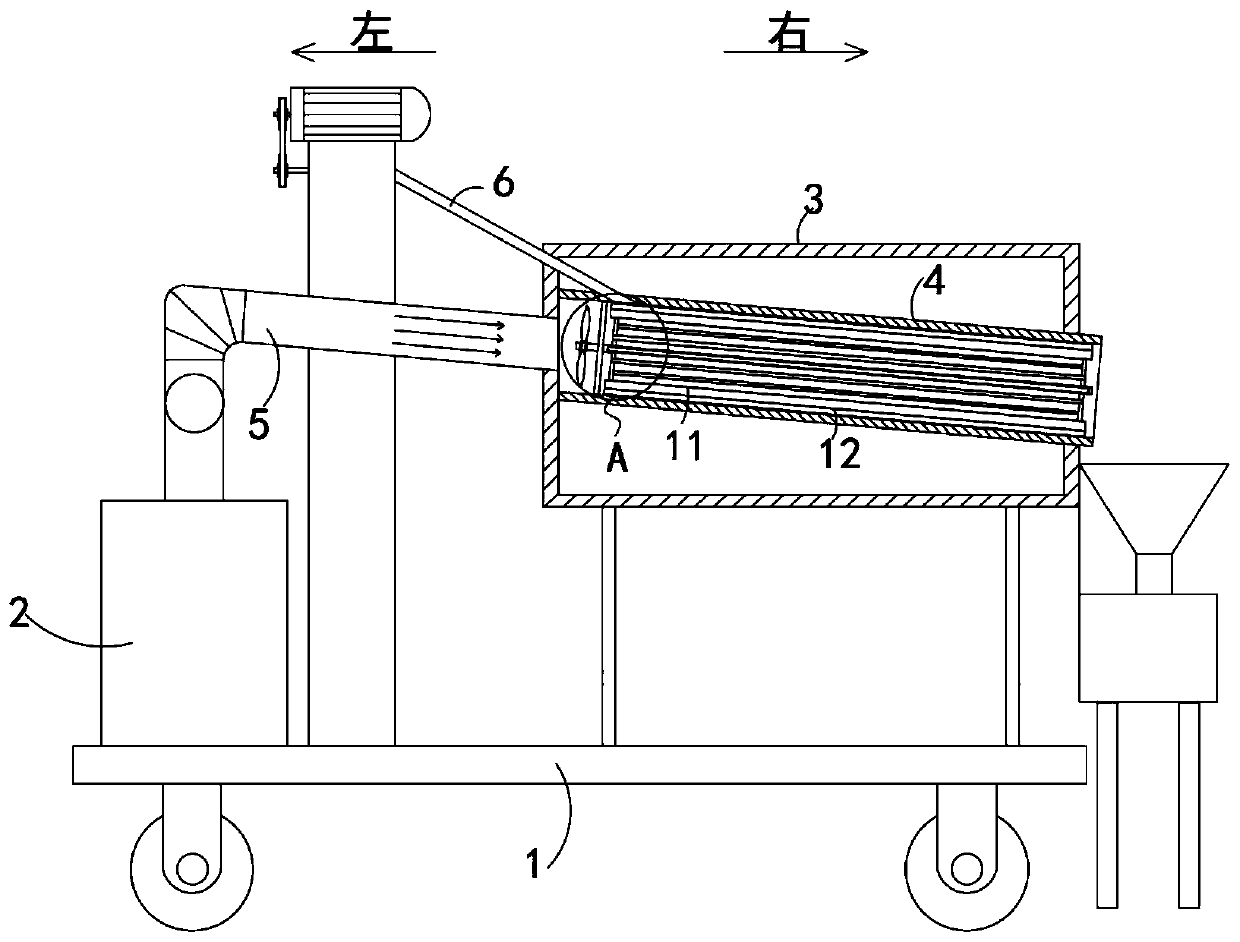

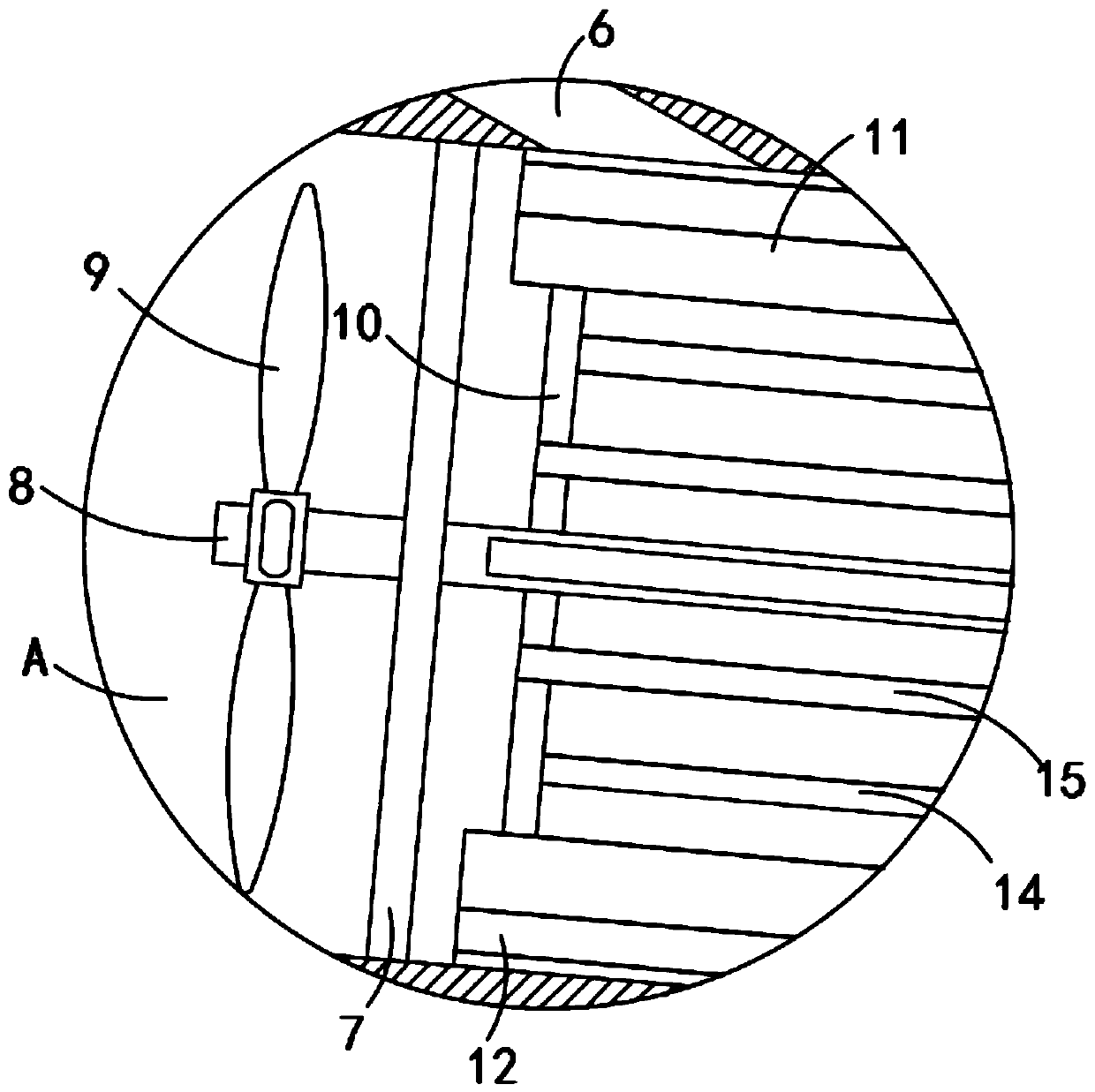

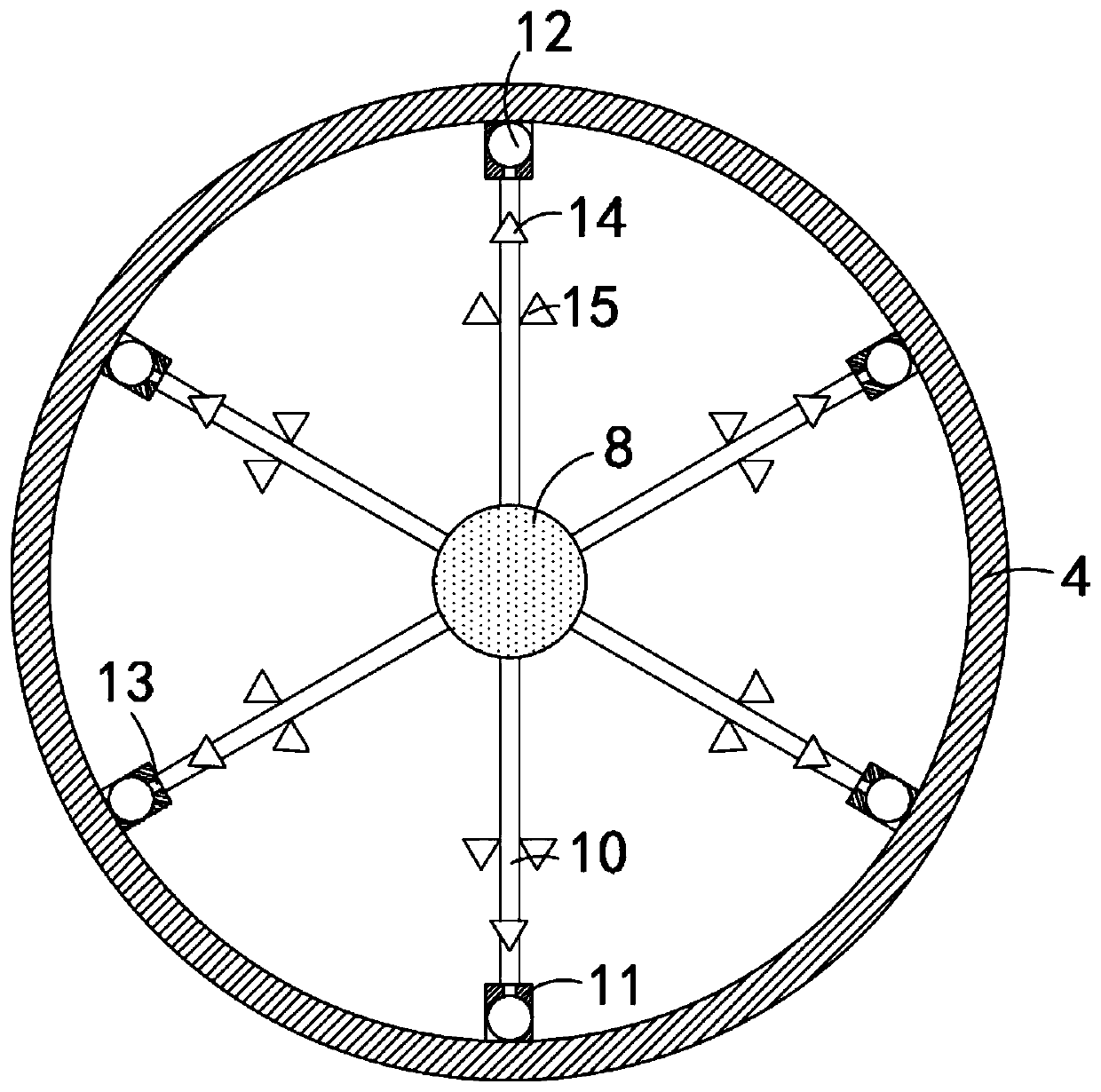

[0019] Such as Figure 1-3 As shown, a kind of energy-saving and environment-friendly drying machine comprises frame body 1, and the upper end of frame body 1 is provided with hot blast stove 2 and drying box 3, and drying box 3 is provided with drying pipe 4, and the left end of drying pipe 4 is connected with drying box The inner wall of 3 is fixedly connected, and the right end of the drying pipe 4 passes through the right inner wall of the drying box 3 and extends to the outside, wherein, the grains dried by the drying pipe 4 are discharged from the right end, and the dried grains are collected by an external collection device. The grains collected are collected, the left end of the drying pipe 4 is communicated with an air duct 5, and the left end of the air duct 5 is communicated with the air outlet end of the hot blast stove 2. It should be noted that the hot blast produced by the hot blast stove 2 enters through the air duct 5. In the drying pipe 4, and the flow direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com