Phase-change heat storage system with stirrer

A phase change heat storage and agitator technology, which is applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of insufficient utilization of phase change materials, increased heat storage costs, and low heat storage efficiency. Achieve the effect of improving utilization rate and heat storage efficiency, reducing heat storage cost and improving stirring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

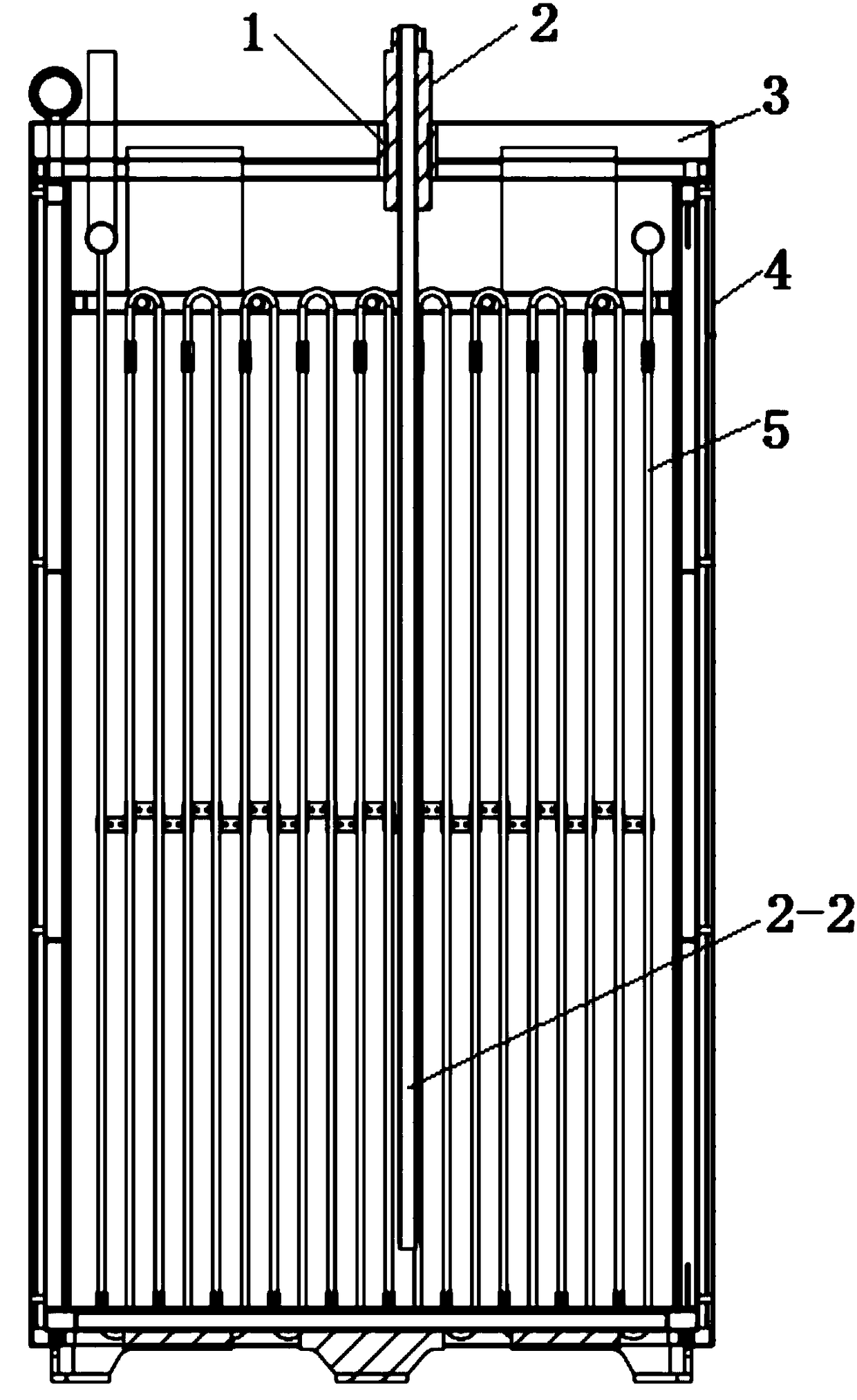

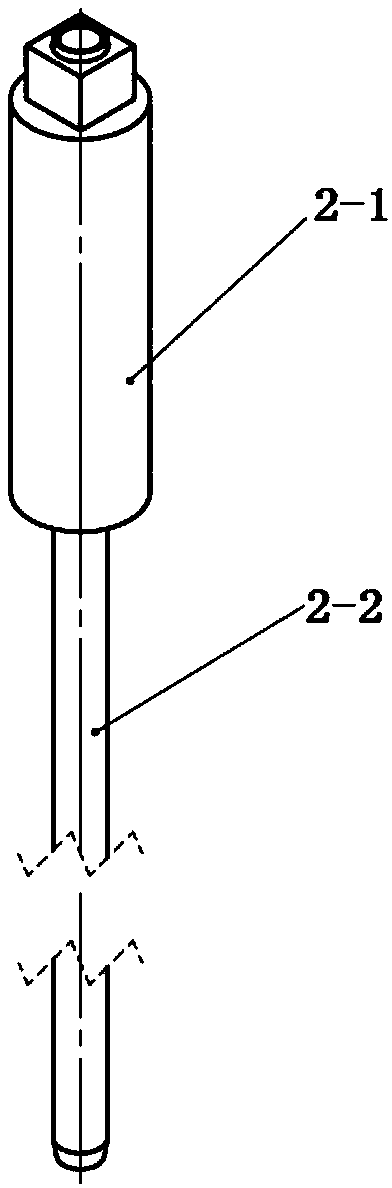

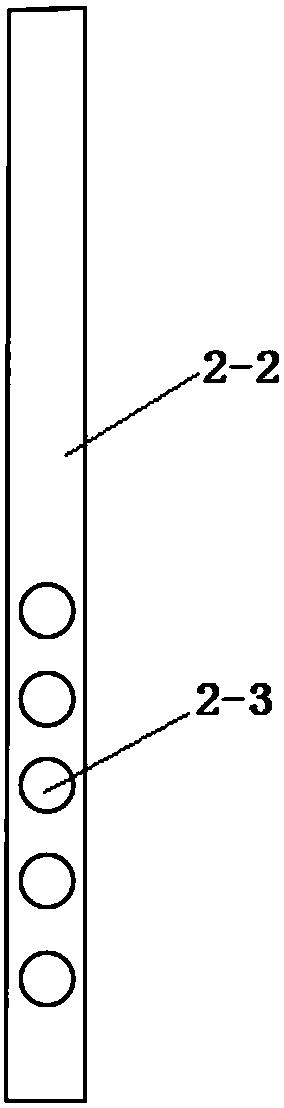

[0037] The phase change heat storage system with agitator includes a heat storage tank 4, an upper cover 3 and a heat exchanger 5. The heat storage tank 4 is a barrel-shaped structure with an open top, and an upper cover 3 is provided on the top. The heat exchanger 5 is arranged inside the heat storage tank 4, and the center of the upper cover 3 is provided with a through hole passing through the upper cover. The inner wall of the through hole is provided with threads, and a nitrogen pipe 2 is vertically arranged in the through hole. The nitrogen pipe 2 comprises an outer pipe 2-1 and an inner pipe 2-2;

[0038] The phase-change heat storage system with a stirrer of the present invention feeds high-pressure nitrogen gas into the bottom of the heat storage tank 4 through the nitrogen pipe 2, and blows the phase-change material solid deposited at the bottom of the heat storage tank 4 by the strong airflow formed by the high-pressure nitrogen gas, The floating and the upper liqui...

Embodiment 2

[0045] The phase change heat storage system with agitator includes a heat storage tank 4, an upper cover 3 and a heat exchanger 5. The heat storage tank 4 is a barrel-shaped structure with an open top, and an upper cover 3 is provided on the top. The heat exchanger 5 is arranged inside the heat storage tank 4, and the center of the upper cover 3 is provided with a through hole passing through the upper cover. The inner wall of the through hole is provided with threads, and a nitrogen pipe 2 is vertically arranged in the through hole. The nitrogen pipe 2 comprises an outer pipe 2-1 and an inner pipe 2-2;

[0046] The phase-change heat storage system with a stirrer of the present invention feeds high-pressure nitrogen gas into the bottom of the heat storage tank 4 through the nitrogen pipe 2, and blows the phase-change material solid deposited at the bottom of the heat storage tank 4 by the strong airflow formed by the high-pressure nitrogen gas, The floating and the upper liqui...

Embodiment 3

[0054] The phase change heat storage system with agitator includes a heat storage tank 4, an upper cover 3 and a heat exchanger 5. The heat storage tank 4 is a barrel-shaped structure with an open top, and an upper cover 3 is provided on the top. The heat exchanger 5 is arranged inside the heat storage tank 4, and the center of the upper cover 3 is provided with a through hole passing through the upper cover. The inner wall of the through hole is provided with threads, and a nitrogen pipe 2 is vertically arranged in the through hole. The nitrogen pipe 2 comprises an outer pipe 2-1 and an inner pipe 2-2;

[0055] The phase-change heat storage system with a stirrer of the present invention feeds high-pressure nitrogen gas into the bottom of the heat storage tank 4 through the nitrogen pipe 2, and blows the phase-change material solid deposited at the bottom of the heat storage tank 4 by the strong airflow formed by the high-pressure nitrogen gas, The floating and the upper liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com