Firework inner barrel improved structure

A technology for inner cylinders and fireworks, which is applied in pyrotechnics, offensive equipment, weapon types, etc. It can solve problems such as complex procedures, affecting the effect of discharge, and the thickness of overfire mud cannot be freely expanded and contracted, so as to simplify the production process and eliminate the problem of non-contact fire. Guarantee the overall quality and discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below, the present invention will be further described in detail with reference to the drawings and embodiments.

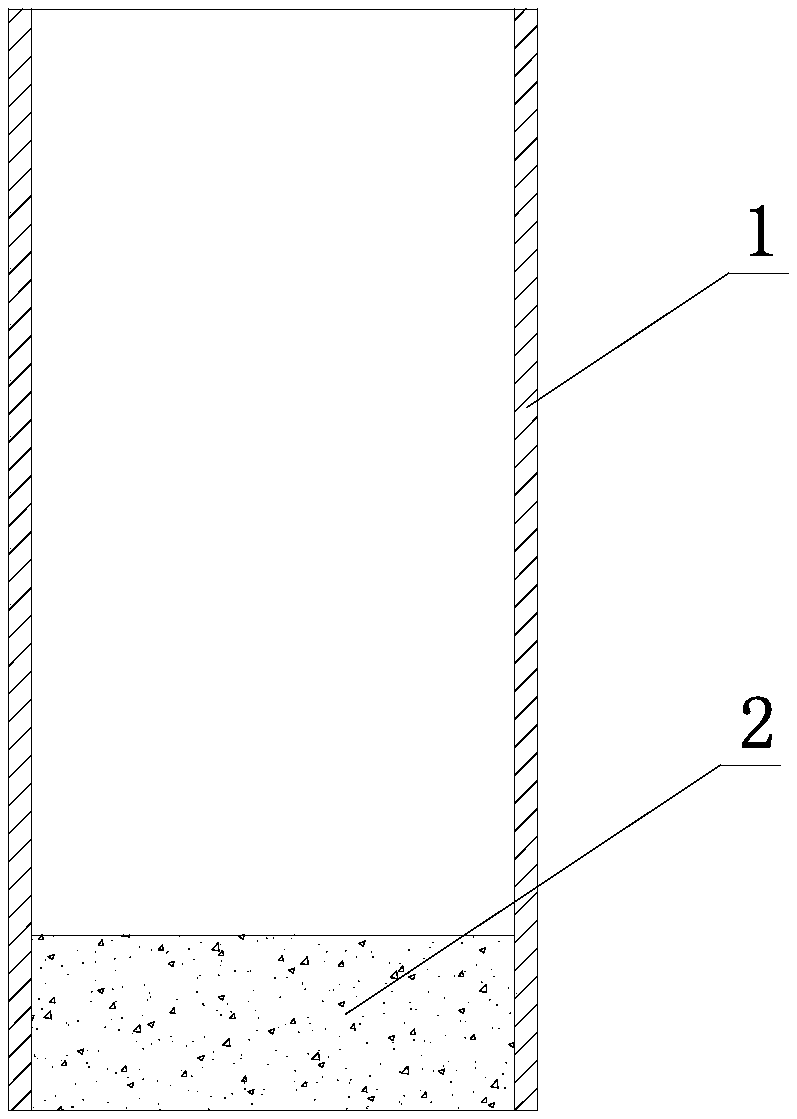

[0011] figure 1 Embodiments of the invention are shown. Its composition: it is composed of a cylinder body 1 and a gunpowder slurry 2 .

[0012] The specific embodiment of the present invention is:.

[0013] An improved structure of a firework inner cylinder, which is characterized in that it includes a cylinder body 1 and an overheating powder 2 filled in the inner cavity of the cylinder, the overheating powder 2 is composed of yellow mud and overheating powder, and is filled in the cylinder body The effect medicine of 1 is ignited by the burning of described powder mud.

[0014] The above are only preferred implementations of the present invention, and the protection scope of the present invention is not limited to the above-mentioned embodiments, and all technical solutions under the idea of the present invention belong to the protection scope of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com