Pneumatic cutting and sampling device for particulate matter and its operating method

A sampling device, pneumatic cutting technology, applied in the direction of sampling device, sampling, measuring device, etc., can solve the problem of changing the characteristics of residual ash particles, so as to ensure the authenticity and effectiveness, and avoid the effect of physical and chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

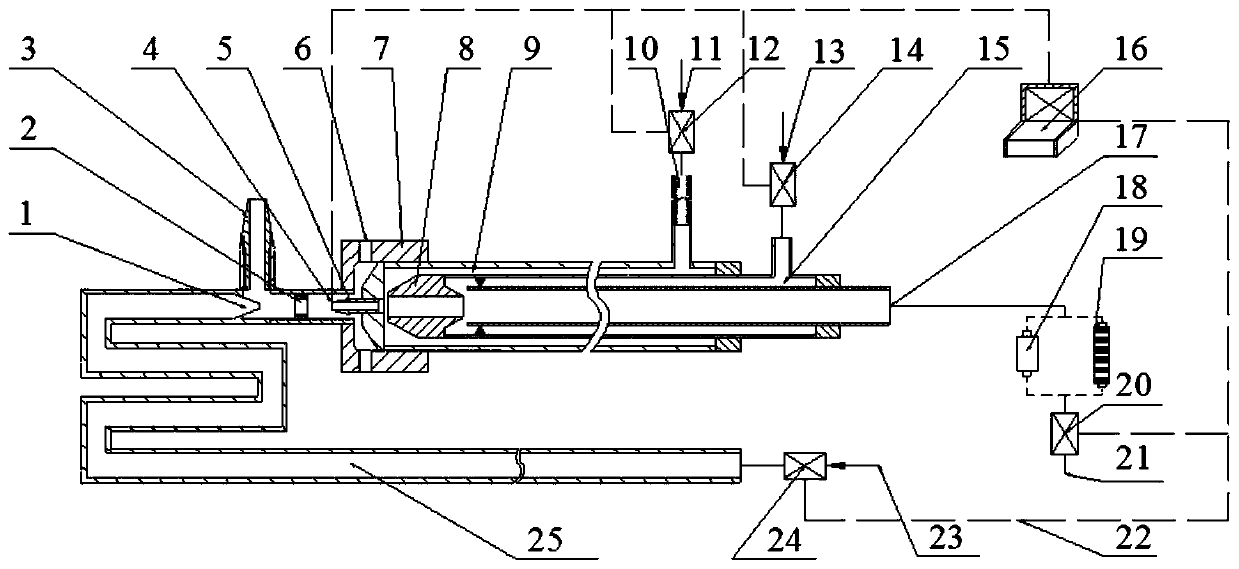

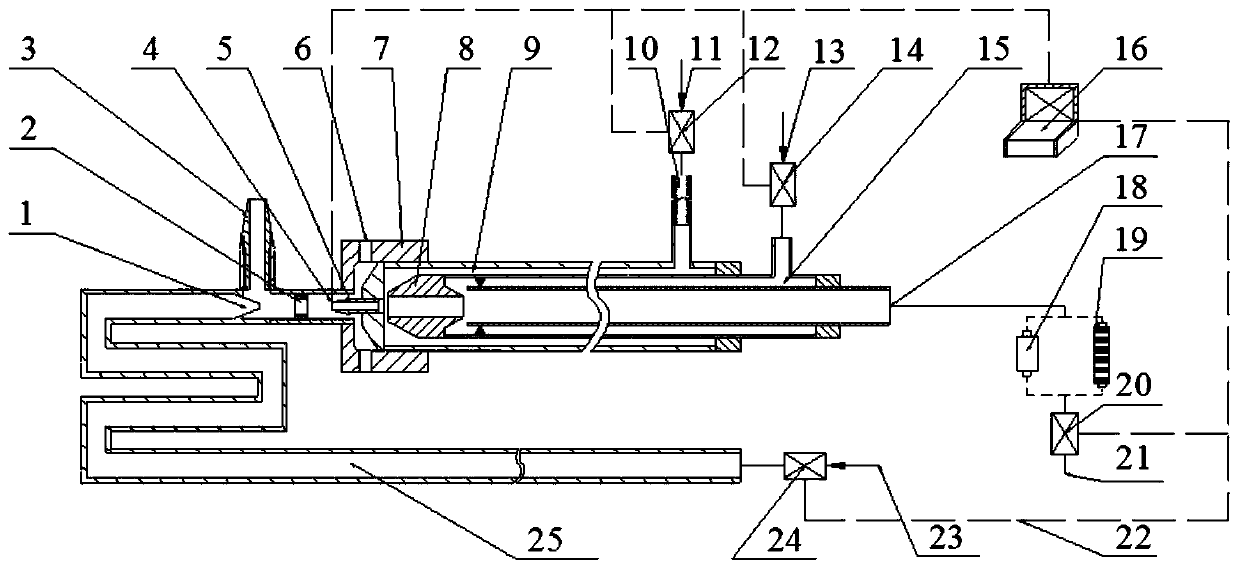

[0036] see figure 1 , a particulate matter pneumatic cutting and sampling system of the present invention, the high temperature pneumatic cutting and particulate matter sampling system includes a sampling part, an inertial separation device, a gun body, a temperature acquisition device, a particulate matter sampling device and a control processor.

[0037] The sampling part is composed of a tapered sampling nozzle 3 , a sample diluent heating tube 25 and an injection mixer 1 . The conical sampling nozzle 3 and the inlet of the ejector mixer 1 are directly connected by thread, and the outlet of the sampling dilution gas heating pipe 25 is connected with the inlet of the ejector mixer 1, and is composed of multi-section elbows to ensure that the sample dilution gas can be fully Heat to make the temperature consistent with the temperature of the sampling position in the flue.

[0038] The inertial separation device consists of an acceleration nozzle 2, a temperature acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com