Automatic timing viscosity meter

An automatic timing and viscometer technology, which is applied in the field of mechanical devices, can solve the problems of inaccurate liquid viscosity measurement, unreasonable viscometer base structure, and unreasonable placement of liquid cups, etc., to achieve a simple and strong promotion of viscosity measurement methods The effect of value, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

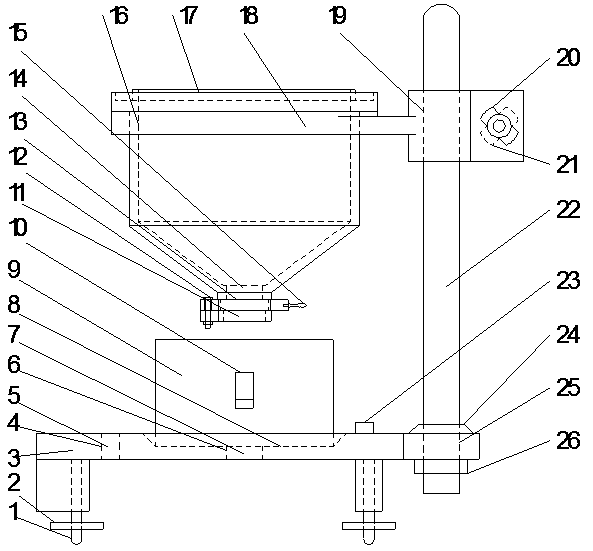

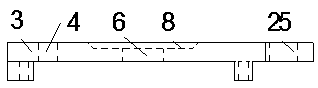

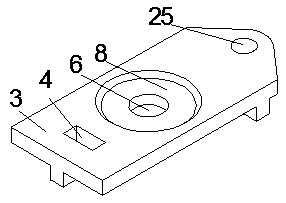

Embodiment 1

[0021] Embodiment 1: as Figure 1-7 As shown, an automatic timing viscometer includes a foot screw 1, a hand wheel 2, a platform base 3, a timing display installation groove 4, a timing display 5, a pressure sensor installation groove 6, a pressure sensor 7, a filling cup positioning groove 8, Filling Cup 9, Filling Cup Handle 10, Auxiliary Outlet 11, Bolt 12, Stop Plate 13, Main Outlet 14, Stop Plate Handle 15, Cross Arm Large Round Hole 16, Liquid Storage Cup 17 , cross arm 18, cross arm small round hole 19, lock bolt 20, lock nut 21, support pole 22, spirit level 23, rubber pad 24, support pole mounting hole 25, support pole nut 26; hand wheel 2 Fixed on the foot screw 1, the foot screw 1 is connected to the platform base 3, the timing display 5 is connected to the pressure sensor 7, the timing display 5 is installed in the timing display installation groove 4 on the platform base 3, and the pressure sensor 7 is installed on the platform base 3 in the pressure sensor insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com