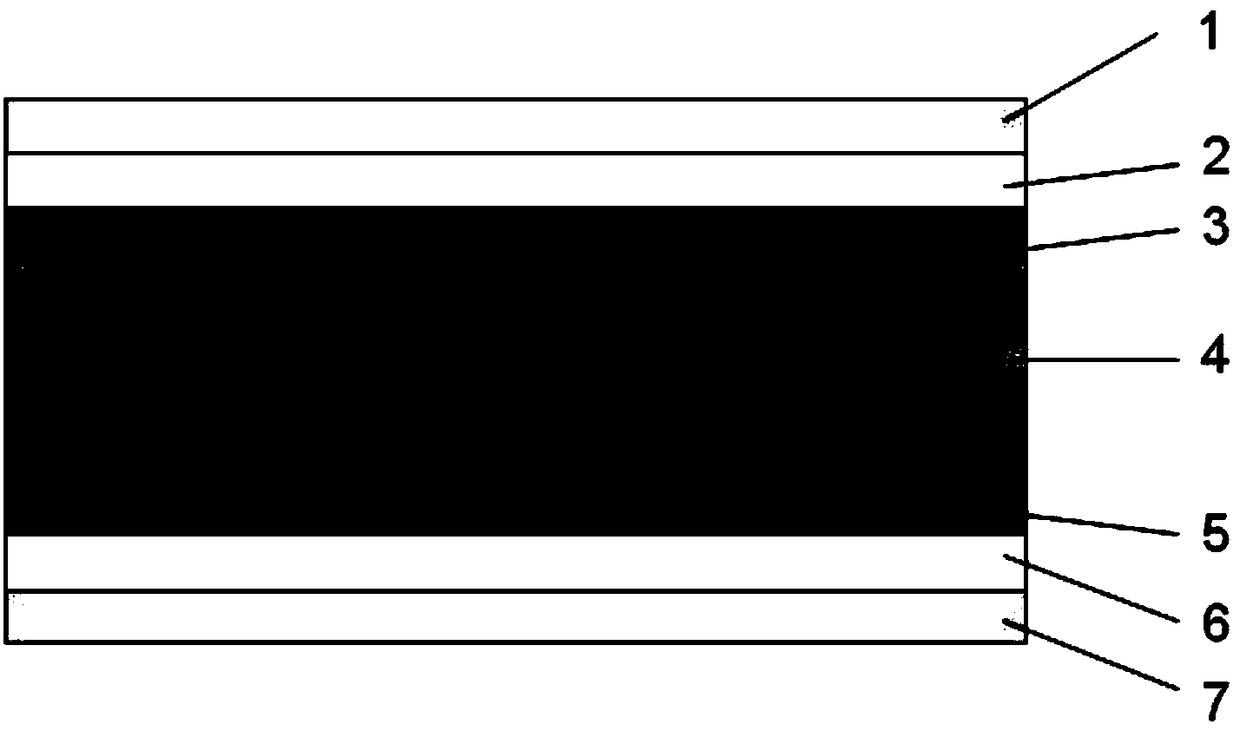

Polymer network liquid crystal dimming device

A technology of liquid crystal dimming and polymerizable compounds, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of poor dimming performance, high device driving voltage, and high total light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

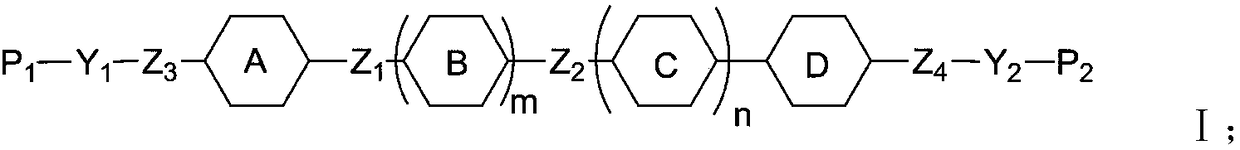

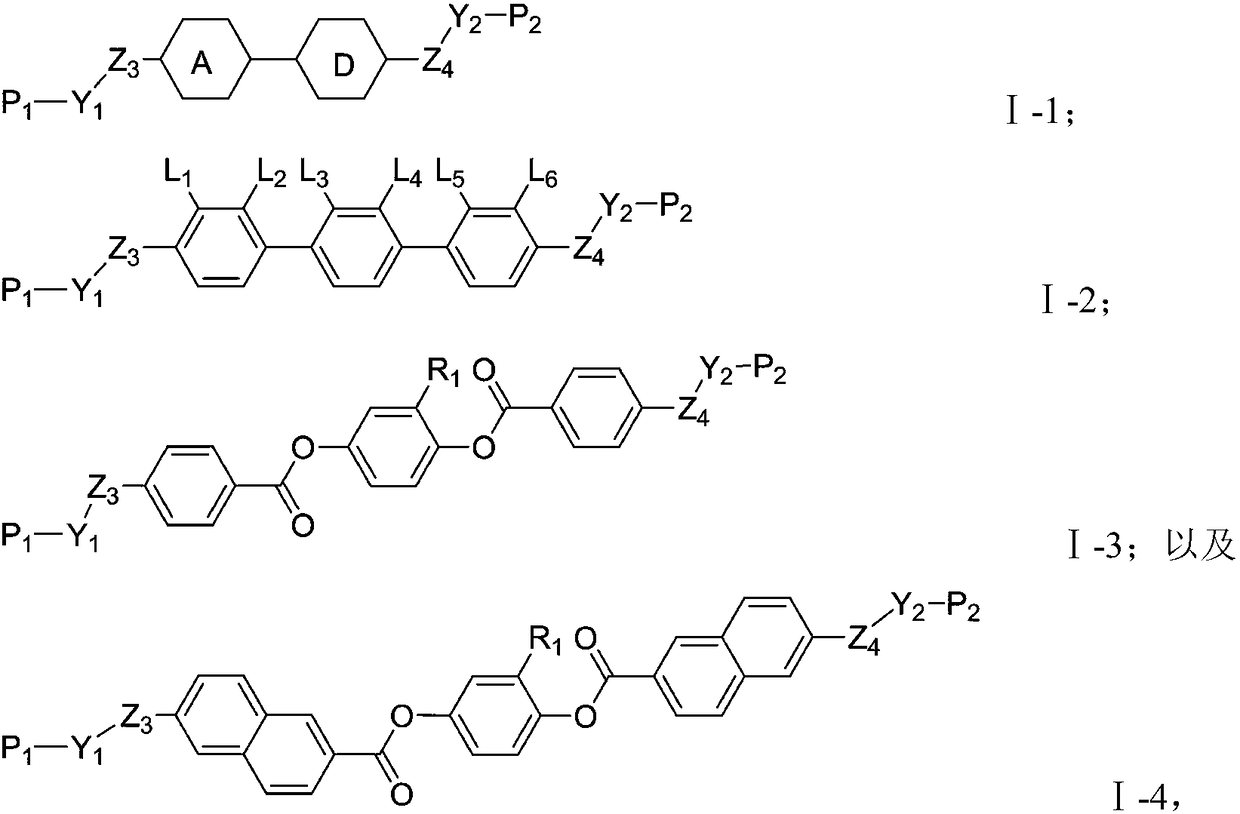

Method used

Image

Examples

Embodiment 1

[0255] The liquid crystal composition HNG700200-100 is prepared by each compound listed in Table 6 and the percentage by weight, HNG700200-100, I-3-13, photoinitiator-184, dichroic dye (will be numbered as 2, 13, 14 dichroic dyes are mixed at a mass ratio of 7:3:20) and mixed evenly at a mass ratio of 92.5:5.8:0.2:1.5, and then vacuum-infused into a 6 μm vertically aligned liquid crystal cell for performance testing and threshold voltage testing and saturation voltage data are shown in the table below:

[0256] Table 6 liquid crystal composition formula and test performance thereof

[0257]

[0258] HNG700200-100, Ⅰ-3-13, photoinitiator-184, dichroic dyes (made by mixing dichroic dyes numbered 2, 13, 14 at a mass ratio of 7:3:20) by mass ratio 92.5: 5.8: 0.2: 1.5 After mixing evenly, vacuum pour it into a 6μm vertically aligned liquid crystal cell, place the liquid crystal cell filled with the mixture at a main light wavelength of 365nm, and apply 30V at a light intensity ...

Embodiment 2

[0263] The liquid crystal composition TS029-1798 is prepared by each compound listed in Table 8 and the weight percentage, and TS029-1798, I-3-13, photoinitiator-184, dichroic dye (will be numbered as 2, 13, 14 dichroic dyes are mixed at a mass ratio of 7:3:20) and mixed evenly at a mass ratio of 92.5:5.8:0.2:1.5, and then vacuum-infused into a 6 μm vertically aligned liquid crystal cell for performance testing and threshold voltage testing and saturation voltage data are shown in the table below:

[0264] Table 8 liquid crystal composition formula and test performance thereof

[0265]

[0266]TS029-1798, Ⅰ-3-13, photoinitiator-184, and dichroic dyes (made by mixing dichroic dyes numbered 2, 13, and 14 at a mass ratio of 7:3:20) by mass ratio 92.5: 5.8: 0.2: 1.5 After mixing evenly, vacuum pour it into a 6μm vertically aligned liquid crystal cell, place the liquid crystal cell filled with the mixture at a main light wavelength of 365nm, and apply 30V at a light intensity o...

Embodiment 3

[0270] Each compound listed in Table 10 and percentage by weight are formulated into liquid crystal composition HNG700200-100, HNG700200-100, I-2-5, photoinitiator-184, dichroic dye (will be numbered as 2, 13, 14 dichroic dyes are mixed at a mass ratio of 7:3:20) and mixed evenly at a mass ratio of 91.5:5.8:0.2:2.5, and then vacuum-infused into a 6 μm vertically aligned liquid crystal cell for performance testing and threshold voltage testing and saturation voltage data are shown in the table below:

[0271] Table 10 liquid crystal composition formula and test performance thereof

[0272]

[0273] HNG700200-100, Ⅰ-2-5, photoinitiator-184, and dichroic dyes (made by mixing dichroic dyes numbered 2, 13, and 14 at a mass ratio of 7:3:20) by mass ratio 91.5: 5.8: 0.2: 2.5 After mixing evenly, vacuum pour into a 6μm vertically aligned liquid crystal cell, place the liquid crystal cell filled with the mixture at a wavelength of 365nm, and apply 30V at a light intensity of 30mw / c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com