An intelligent optimization design method for a low-wind-speed wind turbine generator wind wheel

A wind turbine, optimized design technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve problems such as structure and cost without consideration, reduce blade root load, reduce power cost, and efficiently design blades Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

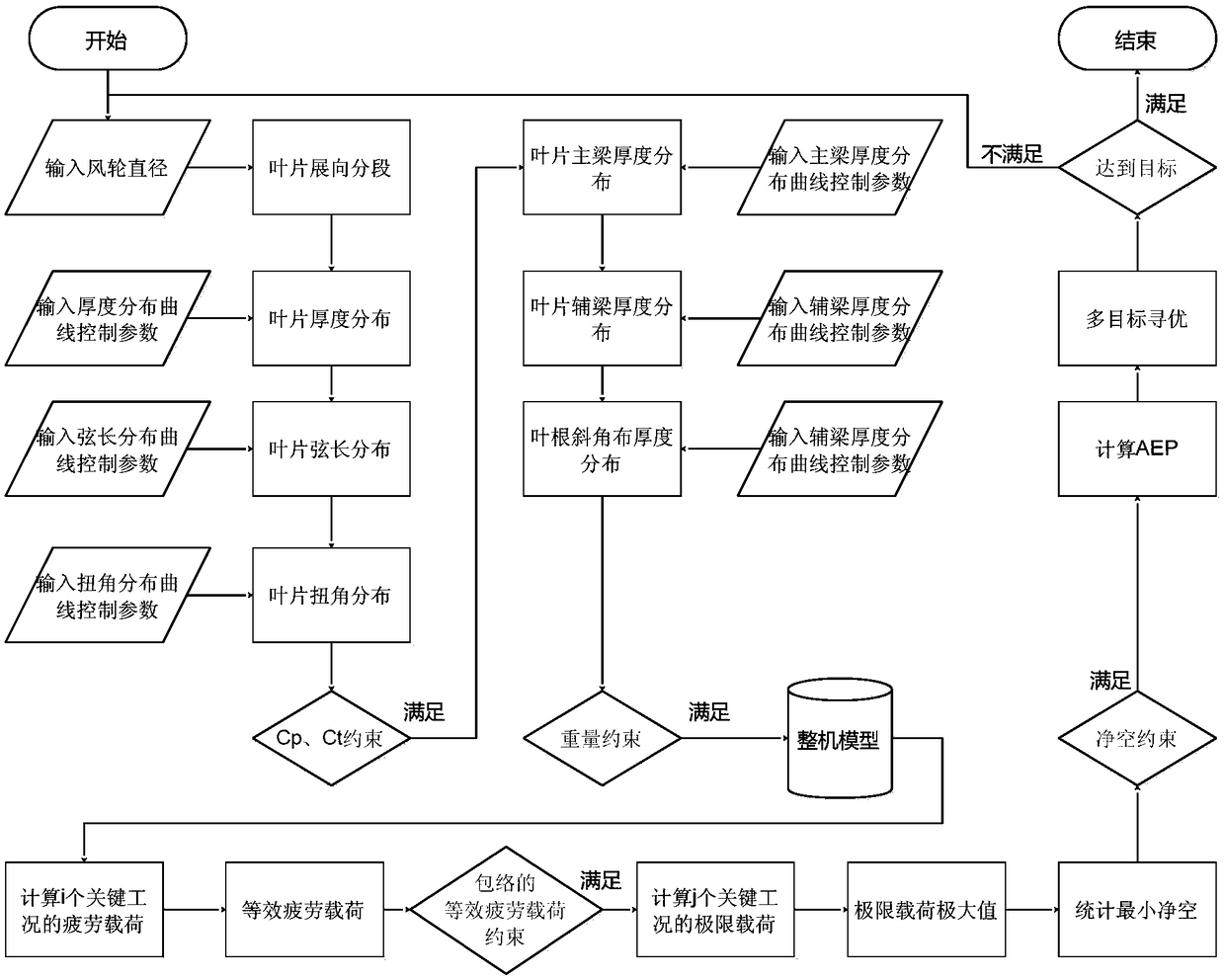

[0039] Refer to attached figure 1 As shown, this embodiment takes the megawatt class long blades for low wind speed as an example to describe the intelligent optimization design method of the wind wheel, and the specific method is as follows.

[0040] The intelligent optimization design method for the wind rotor of the low-wind-speed wind turbine in this embodiment includes the following steps:

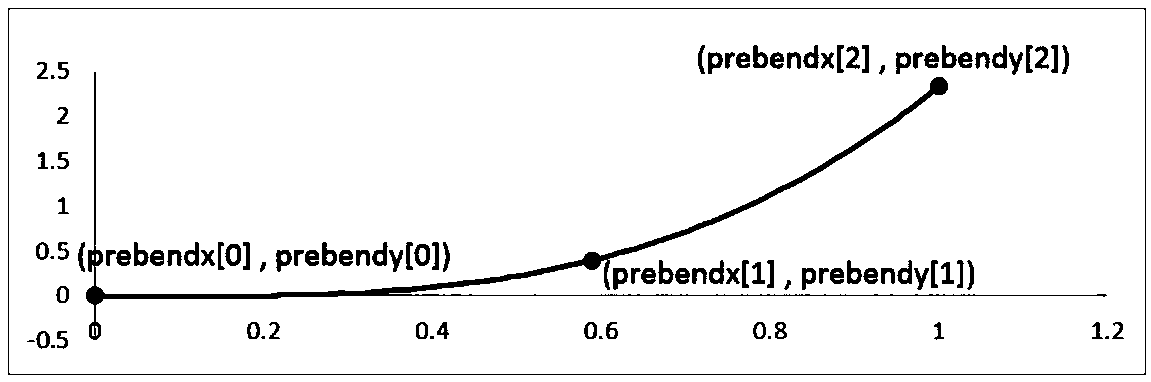

[0041] (1) Select optimization variables from the aerodynamic shape design parameters of wind turbine rotors. The selected aerodynamic shape optimization variables include wind rotor diameter L, chord length, twist angle, thickness distribution, and pre-bending line. All aerodynamic shape optimization variables are selected multiple control points as optimization variables;

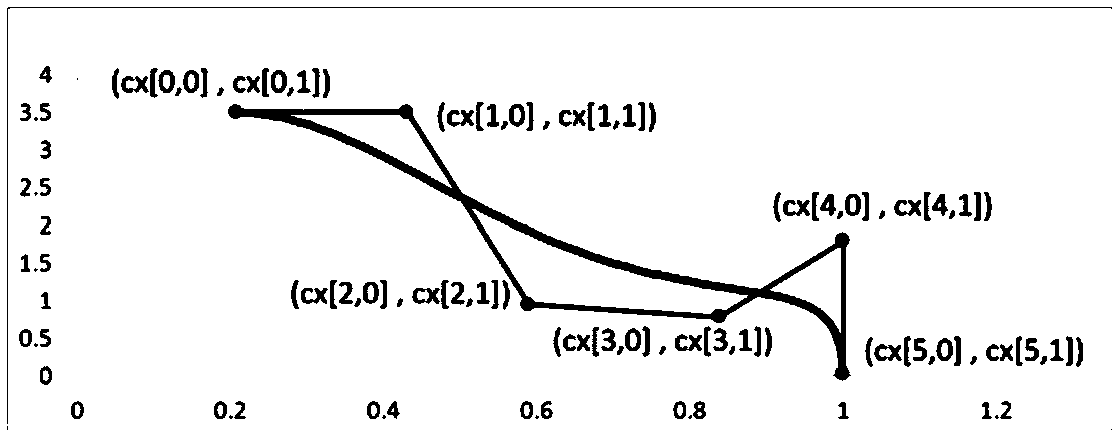

[0042] Among them, the chord length and twist angle distribution are defined by high-order Bezier curves, which can ensure the smooth transition of the blade shape. The thickness distribution adopts a decreasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com