Resin material and laminate

A technology of resin materials and adhesive resins, applied in the field of resin materials, can solve problems such as high cost, large difference in linear expansion coefficient, and poor processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9 and comparative example 1~8

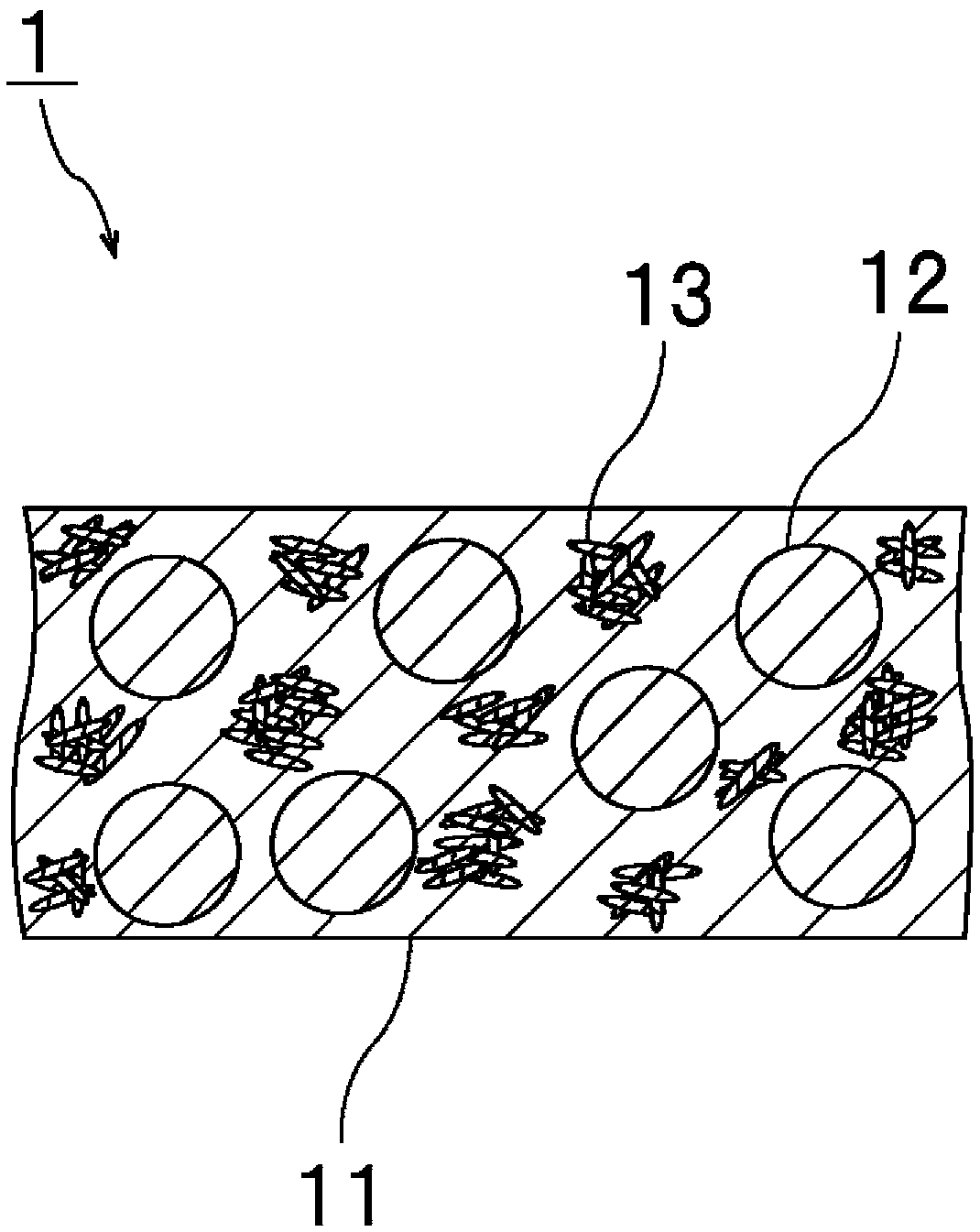

[0259] (1) Manufacture of resin materials

[0260] The ingredients shown in the following Tables 1 and 2 were mixed in the mixing amounts shown in the following Tables 1 and 2, and stirred at a speed of 500 rpm for 25 minutes using a planetary mixer to obtain a resin material.

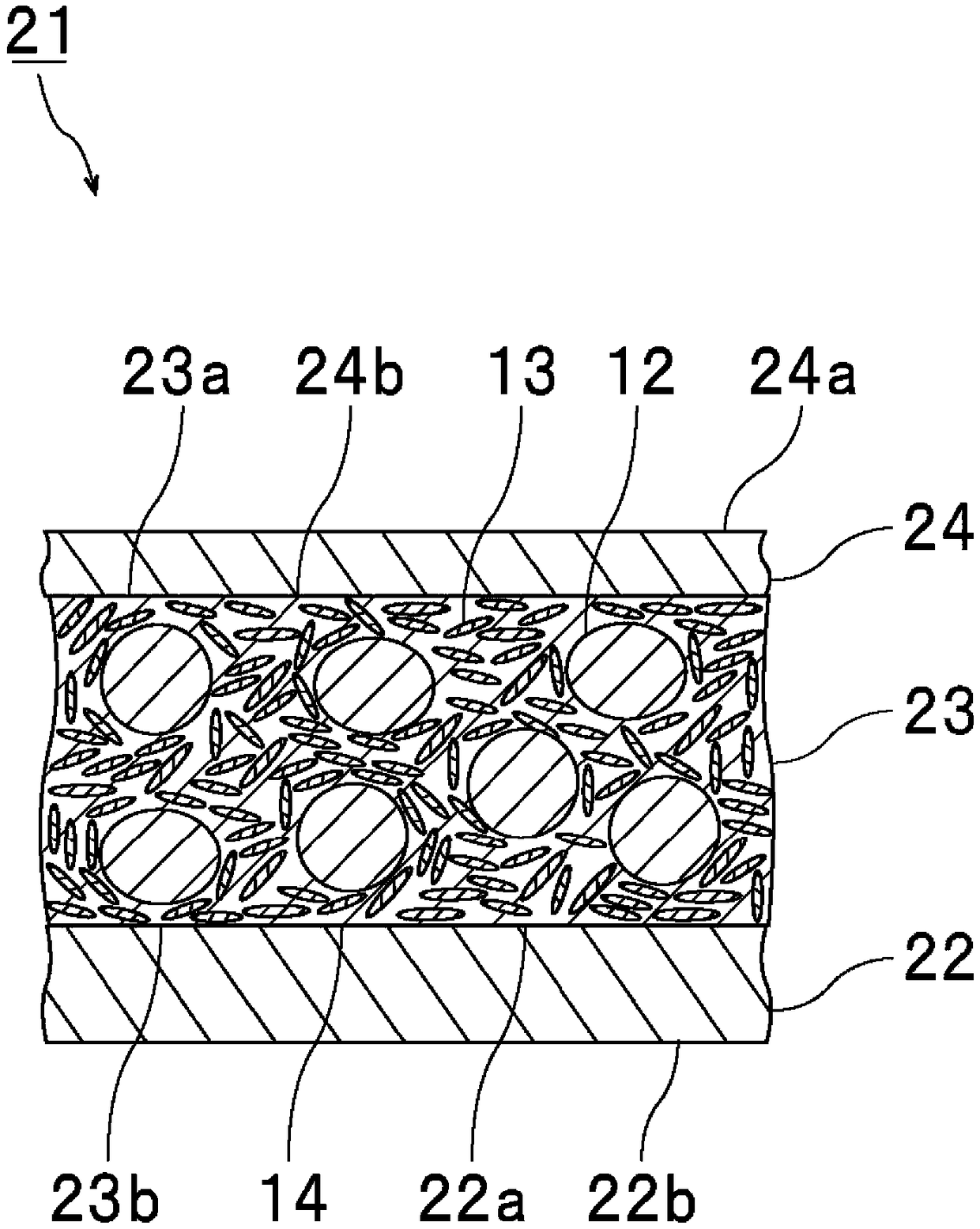

[0261] (2) Manufacture of laminated body

[0262] The obtained resin material was coated on a release PET sheet (thickness 50 μm) so as to have a thickness of 350 μm, and dried in an oven at 90° C. for 10 minutes to form a curable sheet (insulating layer) to obtain a laminated sheet material. Thereafter, the release PET sheet was peeled off, both sides of the curable sheet (insulating layer) were sandwiched between copper foil and aluminum plate, and vacuum pressing was performed at a temperature of 200°C and a pressure of 12 MPa to manufacture a laminated body .

[0263] (Evaluation)

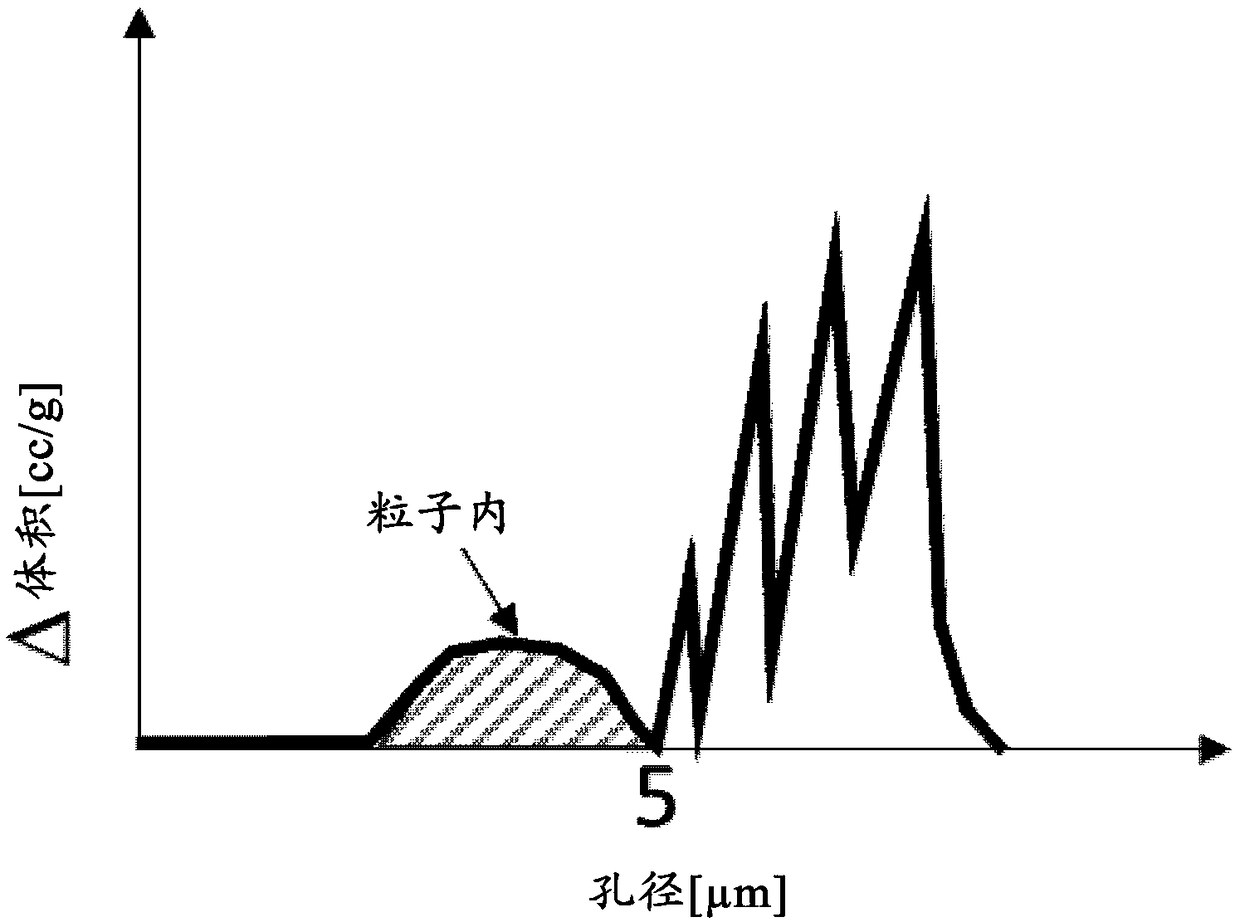

[0264] (1) thermal conductivity

[0265] The obtained laminate was cut into 1 cm squares, and carbon black was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com