Method of manufacturing an optical connection component

An optical connection and component technology, applied in the field of manufacturing optical connection components, can solve the problems of optical fiber mechanical reliability degradation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] [Description of Embodiments of the Invention of the Present Application]

[0045] First, each aspect of the embodiments of the invention of the present application will be pointed out and described individually.

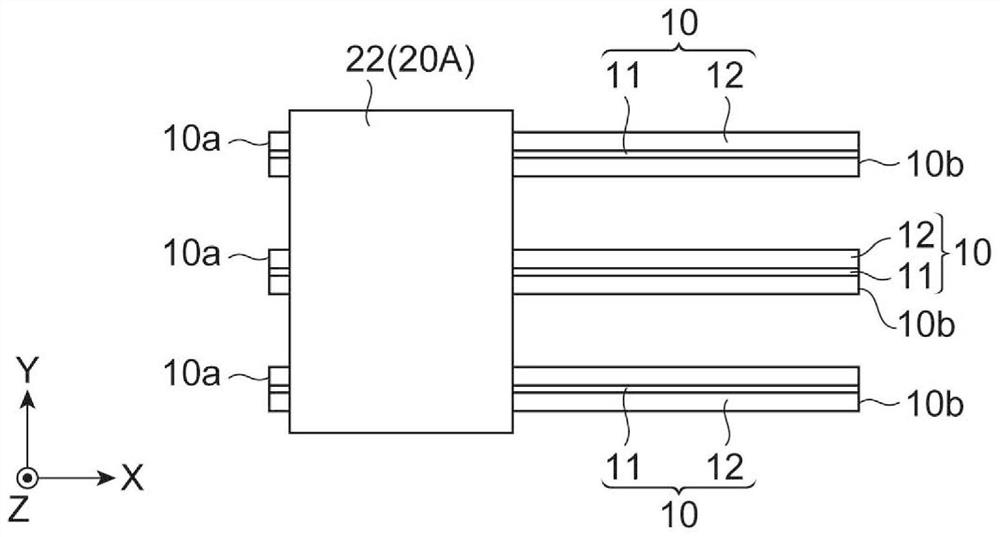

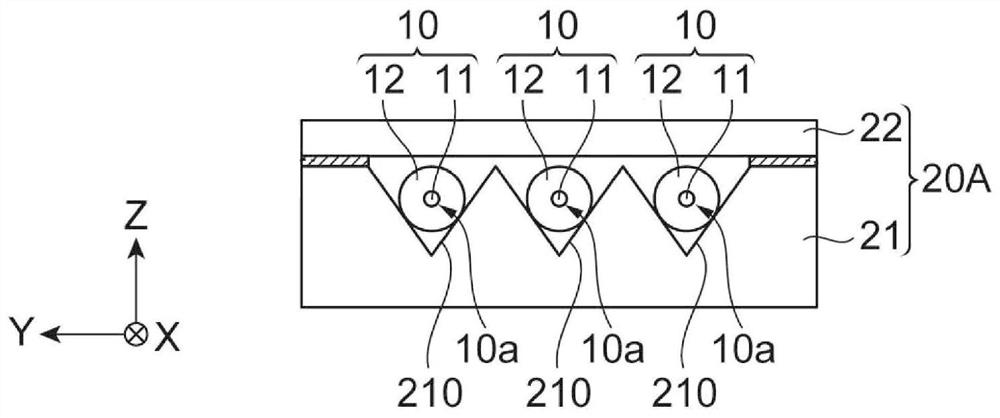

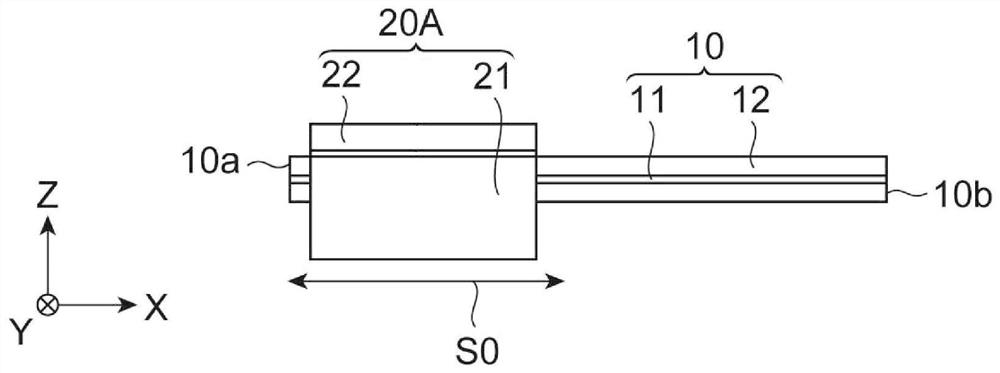

[0046] (1) In the method of manufacturing an optical connection part according to the present embodiment, an optical connection part including a bent optical fiber having a curved shape portion and an optical fiber fixing part attached to the bent optical fiber is manufactured. Specifically, as an aspect of this embodiment, the method includes at least a preliminary step, an installation step, a bending optical fiber manufacturing step, and a fixing step, and the bending optical fiber manufacturing step includes an elastic bending step and a heating step. In a preliminary step, an optical fiber made of silica-based glass is prepared, and a first optical fiber fixing member having a structure for restricting movement of the optical fiber in a direction perpendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com