Continuous casting anti-blocking submersed nozzle

An anti-clogging, immersion technology, used in foundry equipment, casting melt containers, metal processing equipment, etc., can solve the problems of drift vibration, affecting the outflow of molten steel, affecting the strength of the nozzle, reducing secondary oxidation, stable and continuous pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

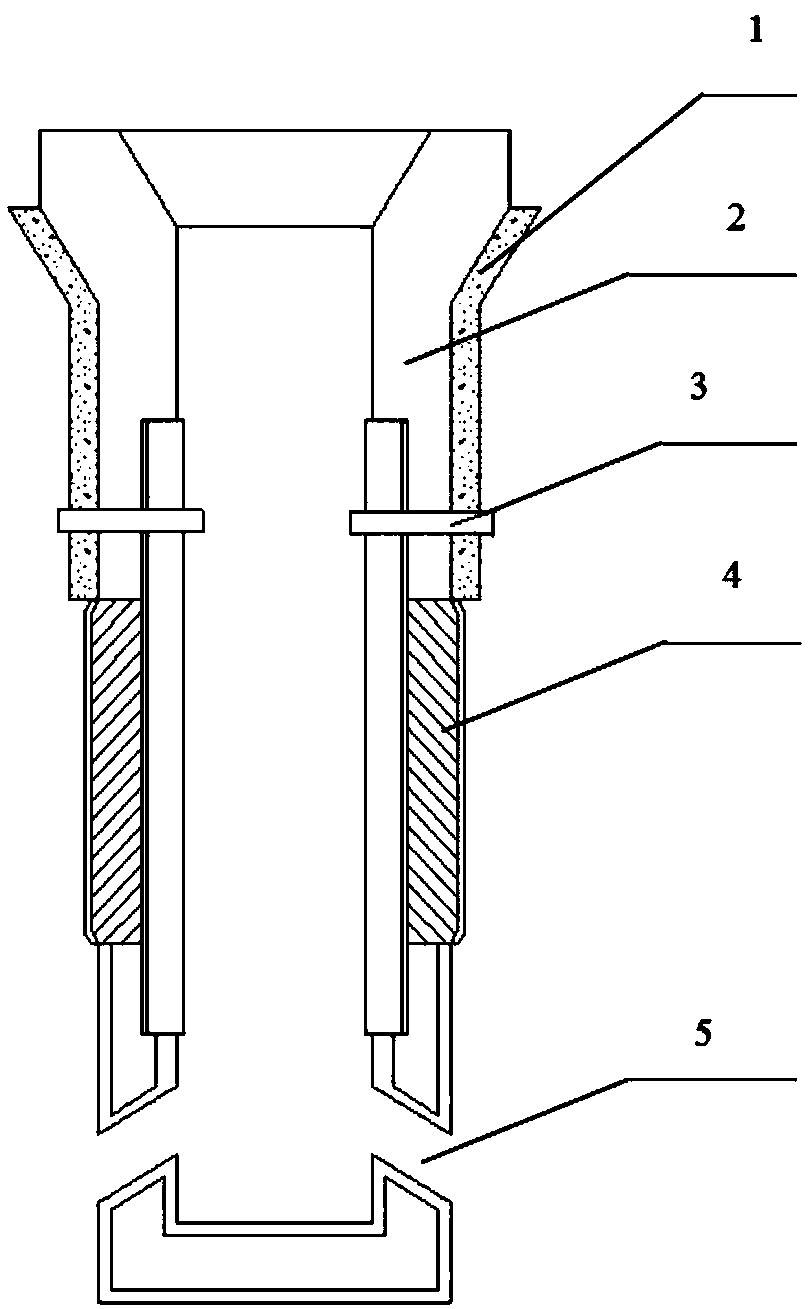

[0023] like figure 1 As shown, a continuous casting anti-clogging submerged nozzle, which includes a nozzle body 2, the inner cavity of the nozzle body 2 is a cylinder, the inlet of the nozzle body 2 is located on the top of the nozzle body 2, and is set in the middle of the nozzle body 2 There is a nozzle slag line 4, two discharge holes 5 are symmetrically arranged on the side wall of the nozzle body 2 near the bottom of the nozzle body 2, and the discharge holes 5 are inclined downward from the inside to the outside of the nozzle body 2.

[0024] Insulation cotton 1 is arranged outside the side wall of the nozzle body 2 between the top of the nozzle body 2 and the nozzle slag line 4 .

[0025] On the side wall of the nozzle body 2, a pair of argon blowing inlets 3 are arranged symmetrically. The argon blowing inlet 3 is arranged above the nozzle slag line 4 and close to the nozzle slag line 4. It runs through the side wall of the nozzle body 2 and the insulation cotton 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com