Milling fixture for mold steel

A die steel, grinding and milling technology, applied in the direction of clamping, manufacturing tools, grinding workpiece supports, etc., can solve the problems of low cost performance, poor applicability of equipment, large processing errors, etc., achieve good applicability and improve applicability , Good processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

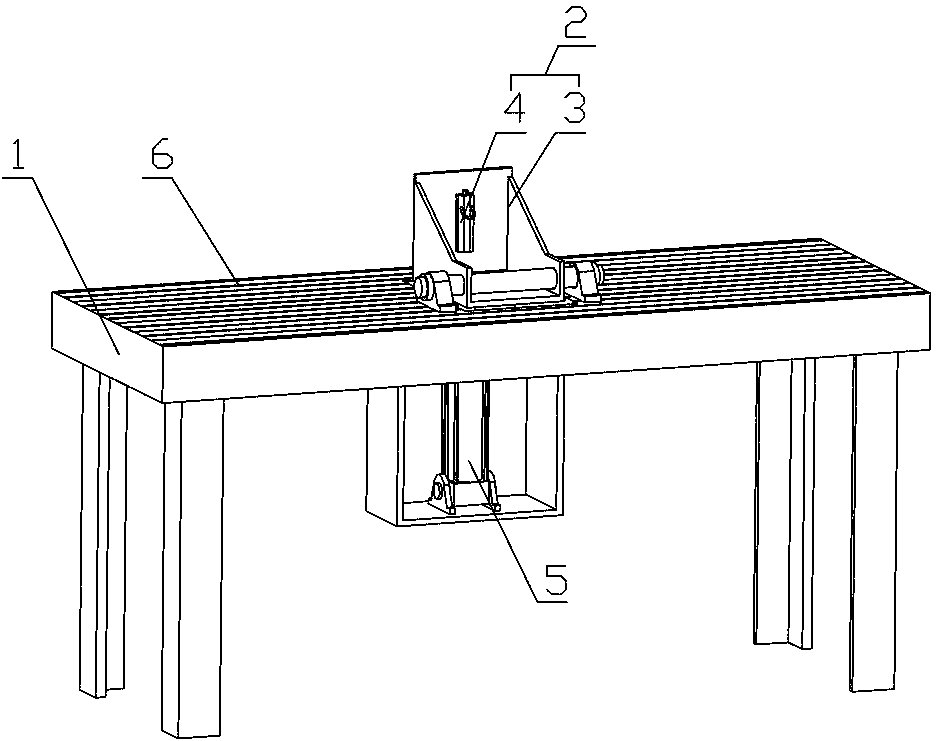

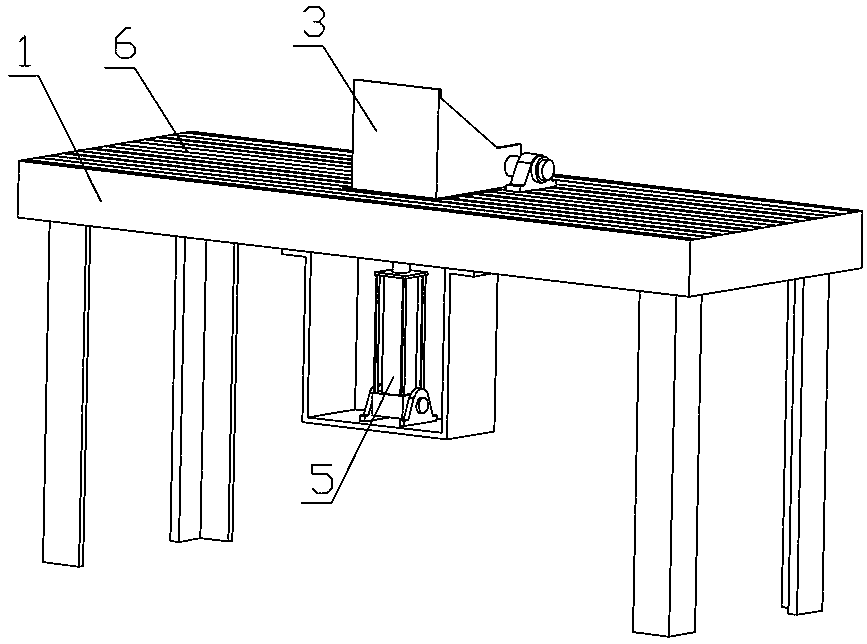

[0014] A special milling fixture for mold steel, which has a pedestal 1 for placing mold steel, and a milling fixture 2 that can adjust the milling angle is installed on the seat surface of the pedestal 1, and the milling fixture 2 has a The magnetic fixture body 3 of mold steel, the front of the magnetic fixture body 3 is facing the milling machine, the back of the magnetic fixture body 3 is equipped with an electromagnet 4, and one end of the bottom of the magnetic fixture body 3 is movably hinged on the pedestal 1, and the other end of the bottom is A lifting cylinder 5 for adjusting the inclination angle of the magnetic clamp body is connected.

[0015] In this embodiment, the front of the magnetic fixture body 3 facing the milling machine is attached to the mold steel.

[0016] In this embodiment, the lifting cylinder 5 is connected to the front end of the bottom of the magnetic clamp body 3 , and the hinge point between the magnetic clamp body 3 and the pedestal 1 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com