Direct printing machine and method for printing on containers by means of direct printing

A direct, container technology, applied in printing, kerning mechanisms, copy/marking methods, etc., can solve problems such as wear, pollution, high installation costs, etc., to achieve the effect of low pollution risk, compact layout, and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] specific implementation plan

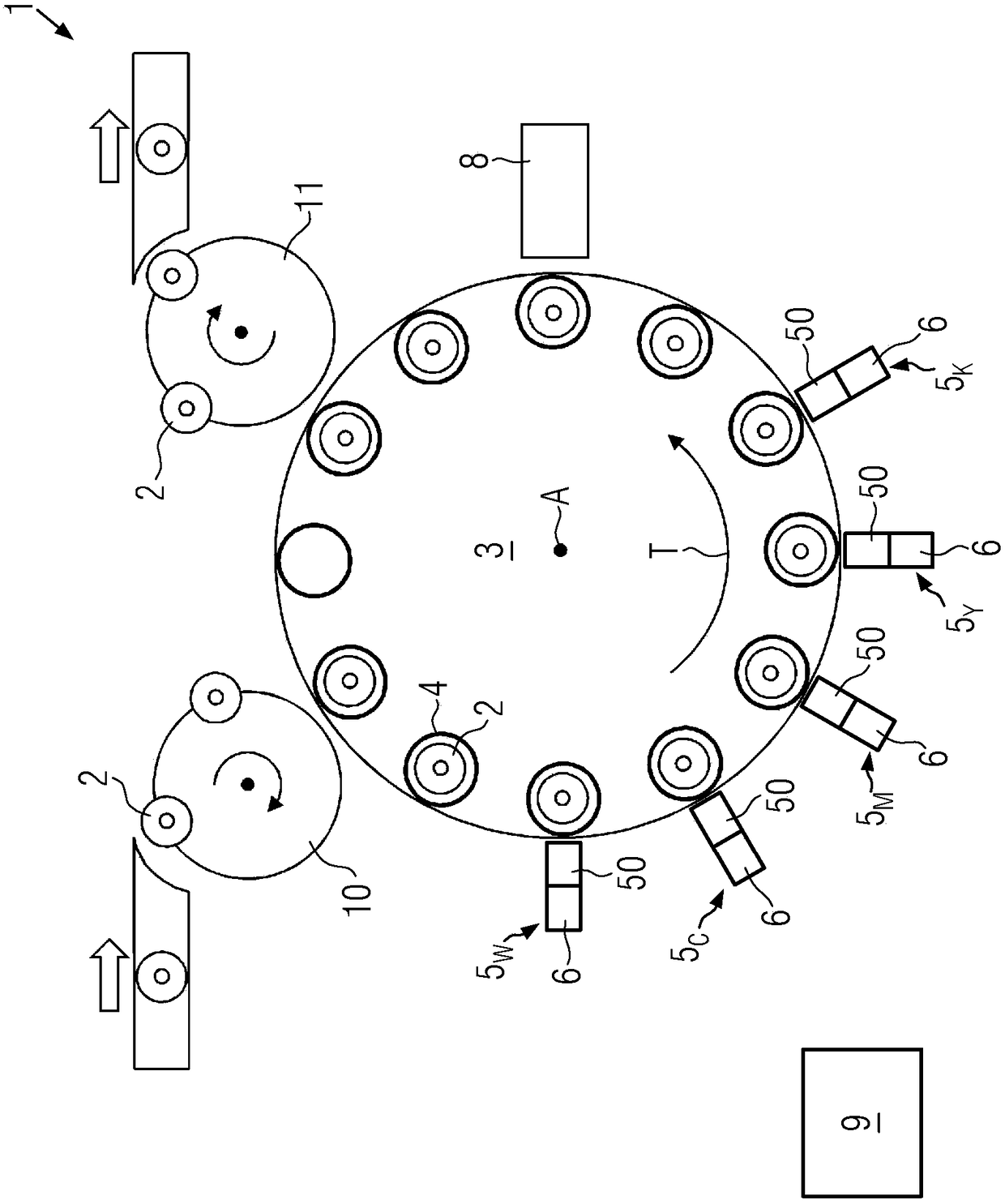

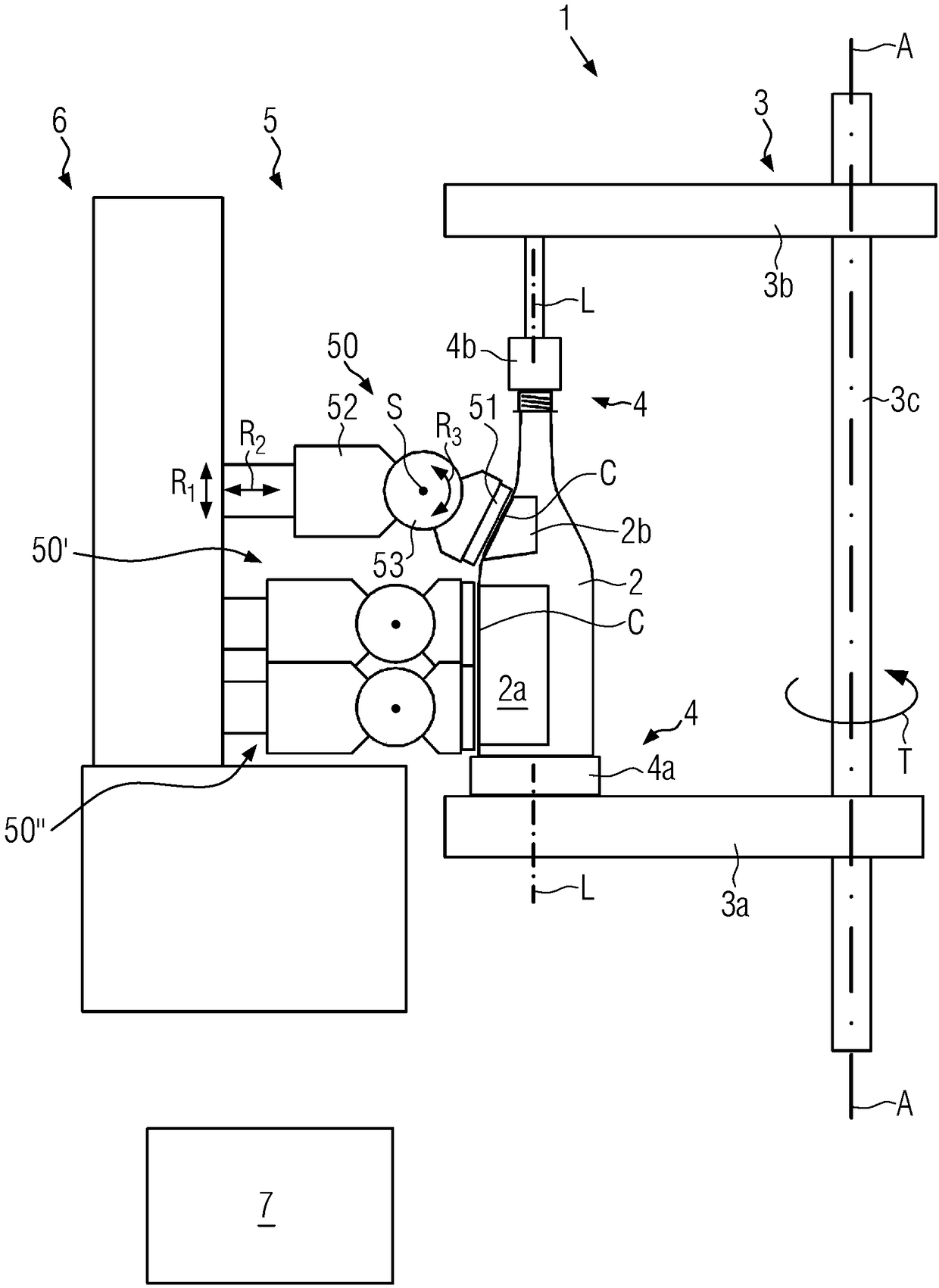

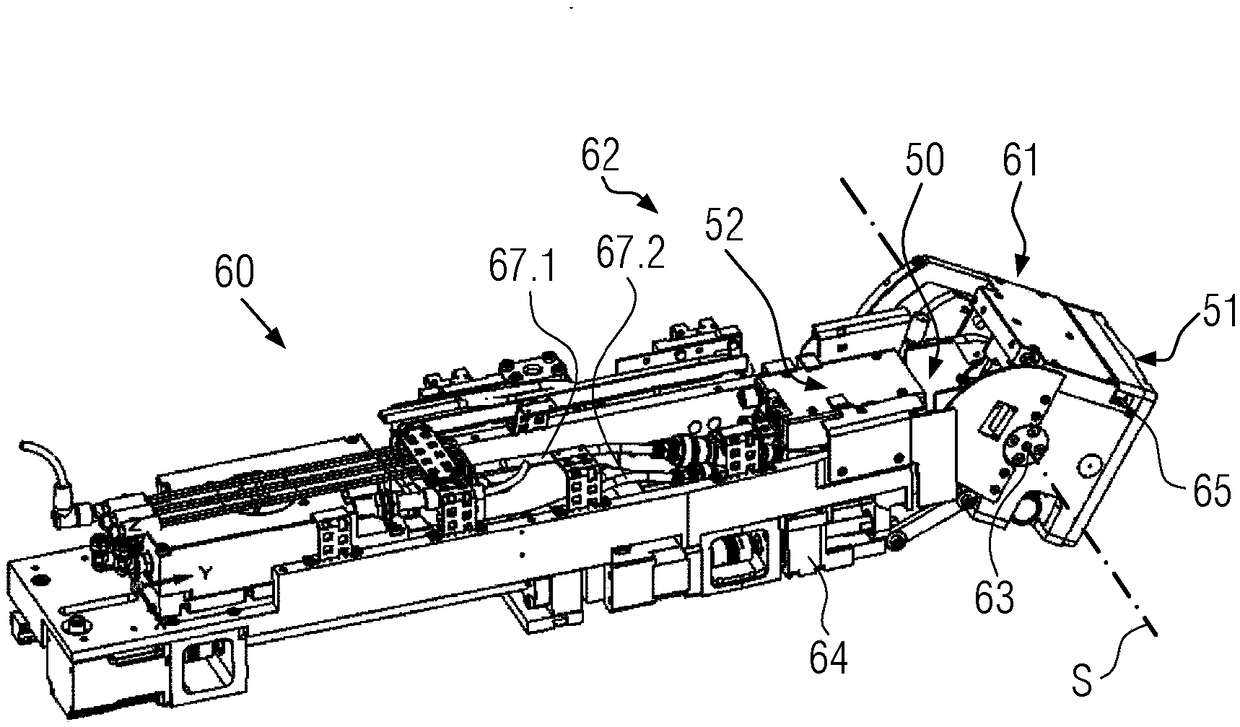

[0047] figure 1 An overview according to an embodiment of the invention of a direct printing machine 1 for printing direct stamps on containers 2 is shown in top view. It can be seen that the containers 2 , for example containing fillings and closures, are transferred by means of the infeed star 10 to the conveyor 3 and accommodated there in the container receptacles 4 . In this accommodated manner the conveyor 3 transports the containers past the direct printing station 5 which is incorporated on the conveyor W 、5 C 、5 M 、5 Y 、5 K And in each case printing is carried out by means of the direct printing module 50 in different colors, corresponding here, for example, to a logo comprising white, cyan, magenta, yellow and black. A multicolor direct print is thus produced on the container 2 . The direct print applied to the container is subsequently cured by means of a curing station 8 and thereby permanently stabilized, for example by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com