Harmless drying device and method for sulfur-containing sludge

A drying device and drying method technology, applied in chemical instruments and methods, separation methods, dehydration/drying/concentrated sludge treatment, etc., to achieve the effects of high treatment efficiency, improved treatment efficiency, and safe operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

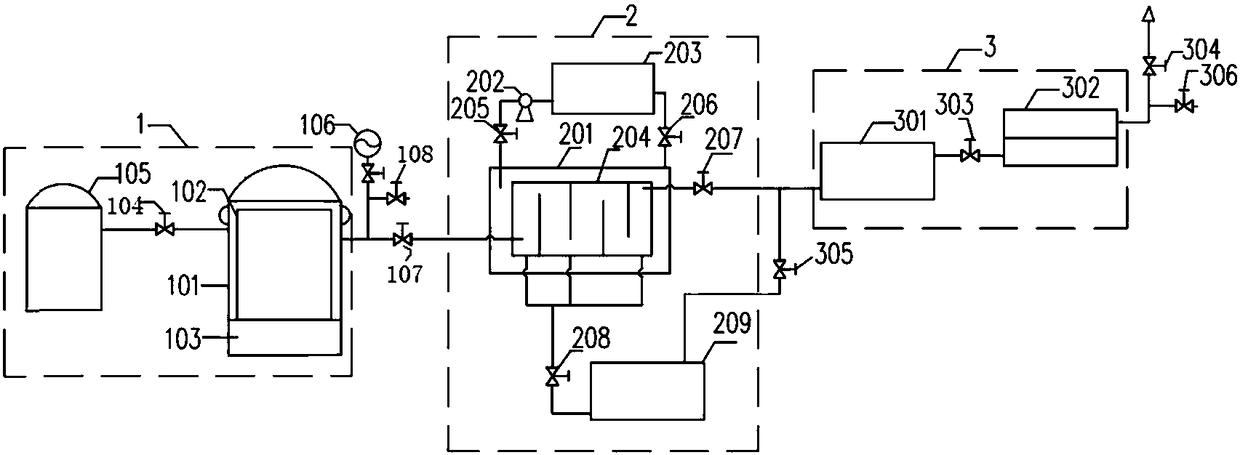

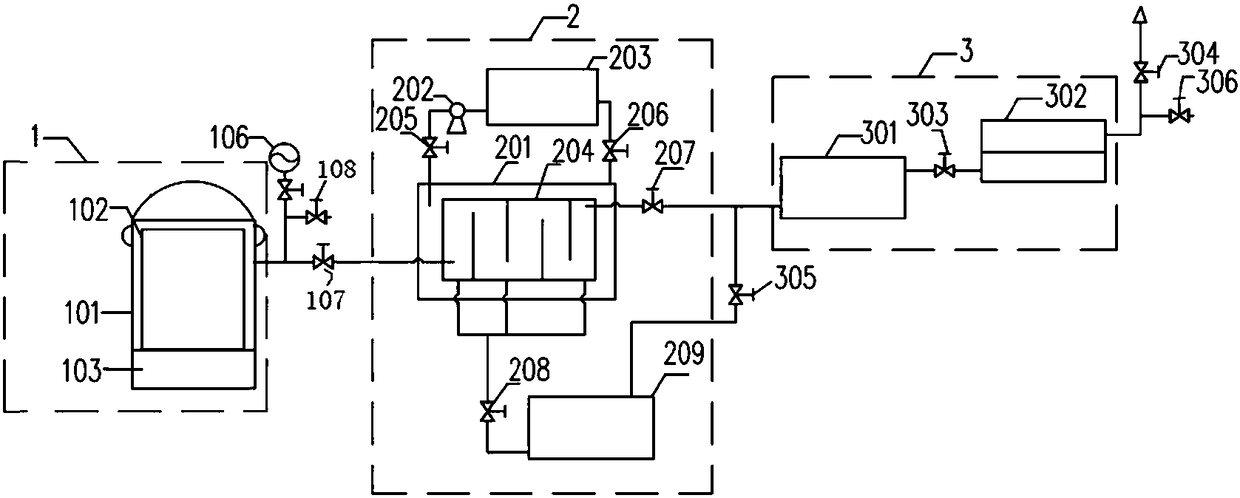

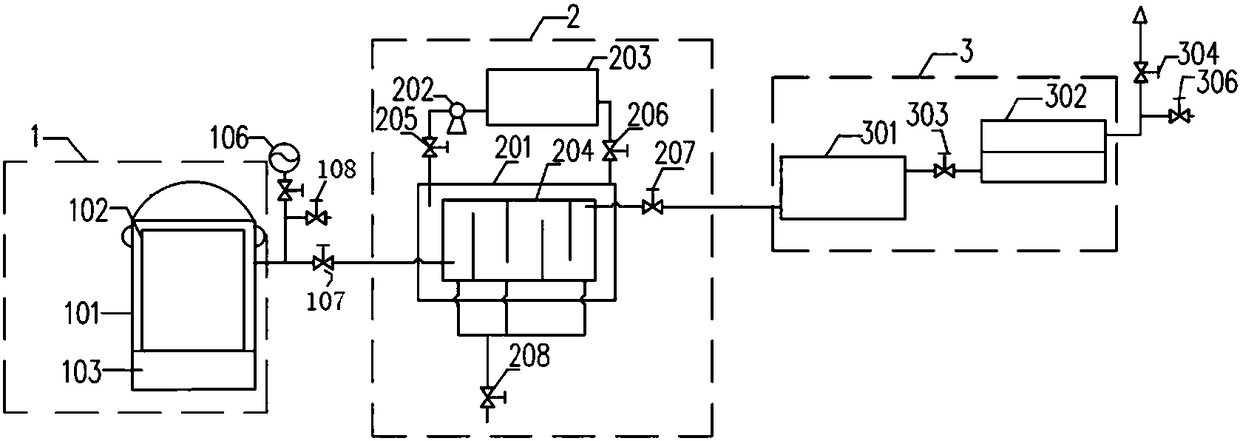

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The embodiment of the harmless drying device for sulfur-containing sludge of the present invention, the schematic diagram of the structure is as follows figure 1 As shown, it includes a sequentially connected sulfur-containing sludge heating device 1, a condensation device 2, and a condensed gas treatment device 3. The sulfur-containing sludge heating device 1 includes a heating tank 101 and a nitrogen tank 105, and a sludge bucket is arranged in the heating tank 101. 102, the heating tank 101 includes a tank body and a cover plate that are tightly fitted, and a partition is provided in the tank body, and the partition board separates the tank inner cavity into a heating chamber 103 located at the lower part and a sludge bucket accommodating chamber located at the upper part. There is a gap between the mud bucket and the tank body, and the gap for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com