Corticotropin preparation method

A technology of corticotropin and ethanol aqueous solution, which is applied in the field of biomedicine, can solve the problems of low corticotropin content, long production cycle, cumbersome process, etc., and achieve the effect of complete extraction, low production cost and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

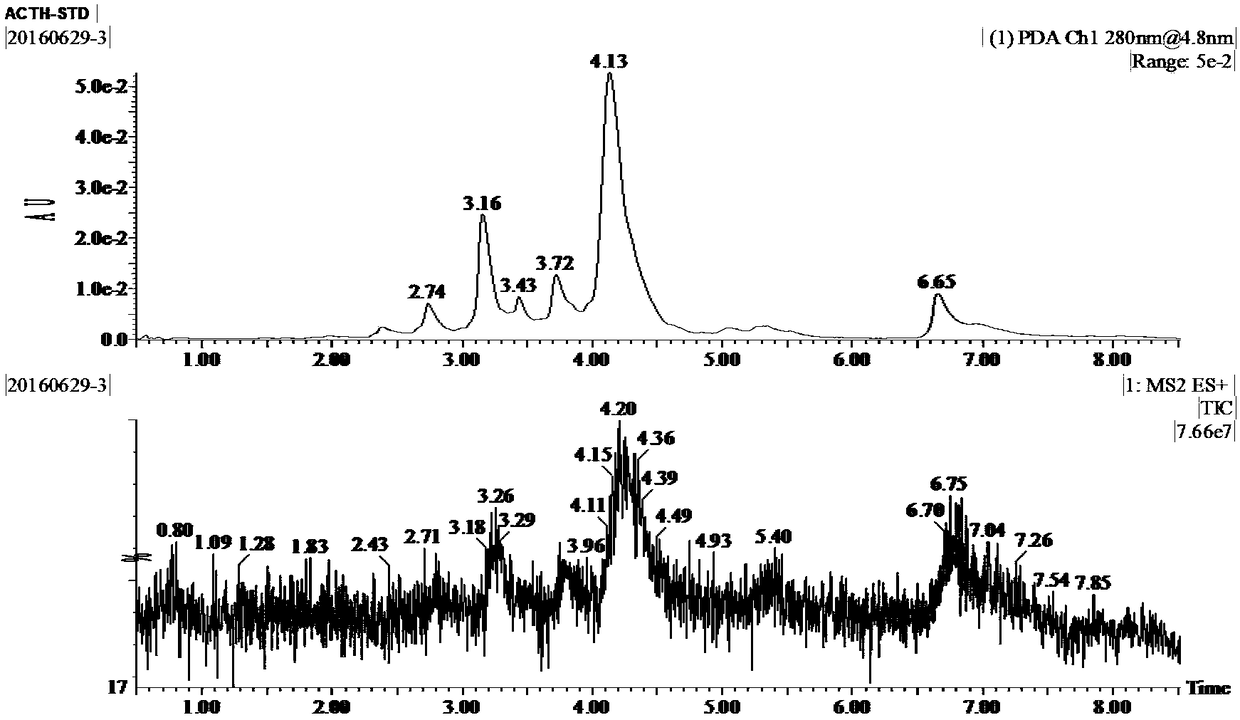

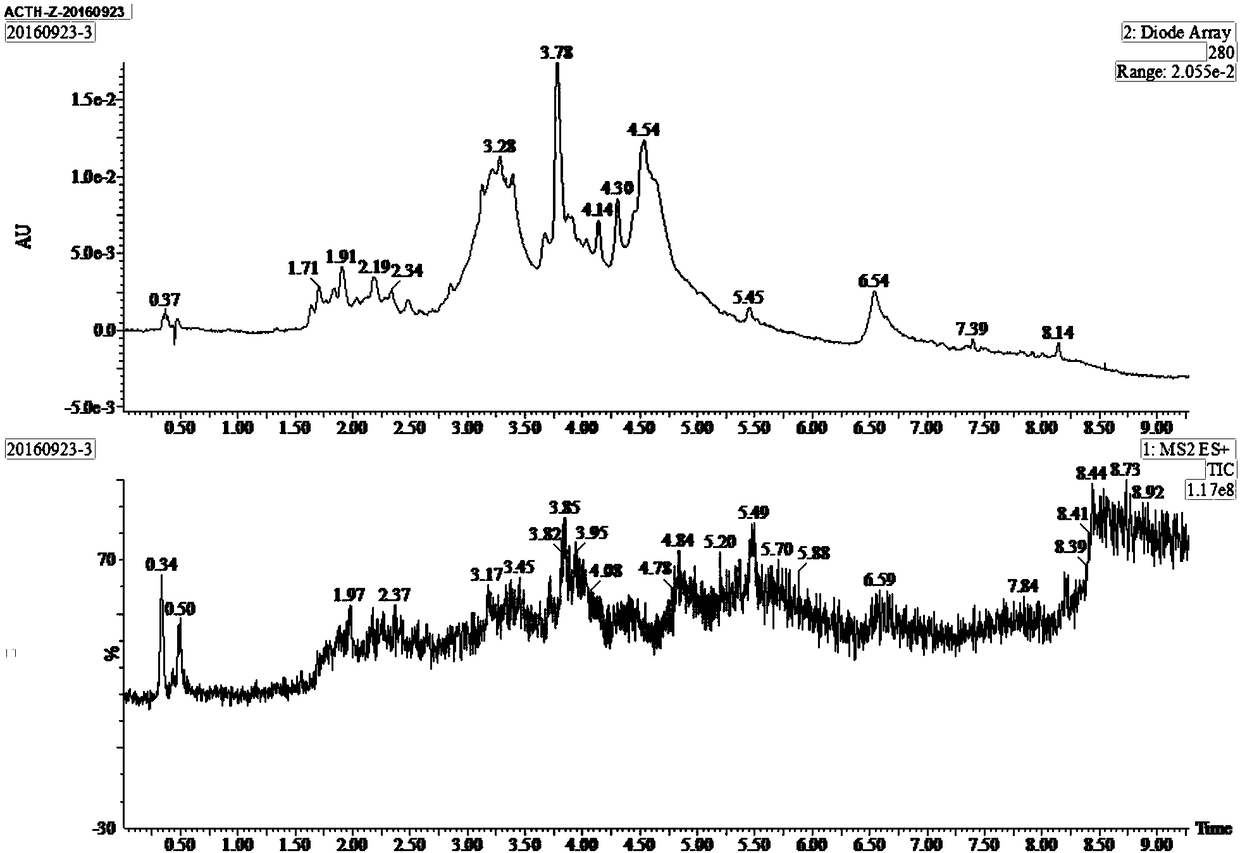

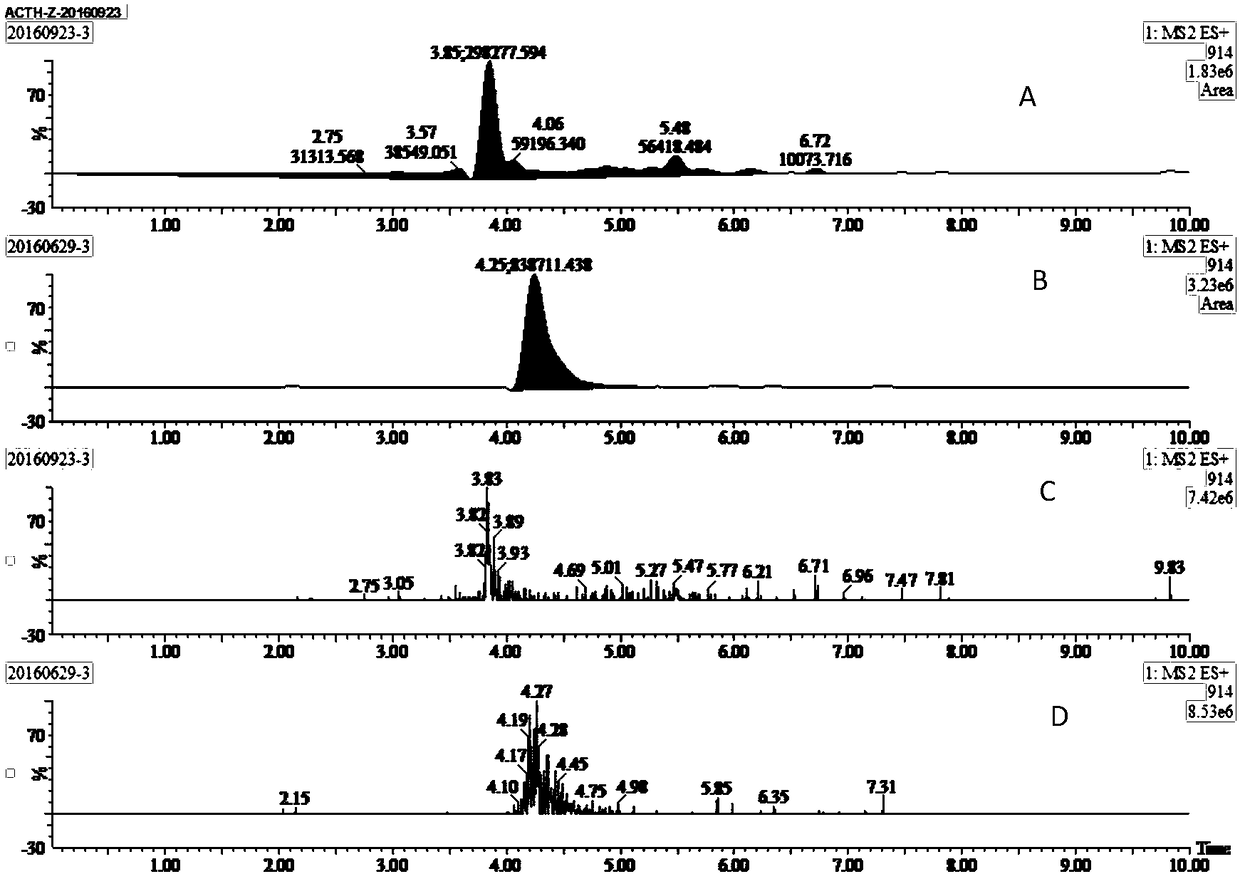

Image

Examples

Embodiment 1

[0038] preparation of corticotropin

[0039] The mixer used in this embodiment is Supor soybean milk machine (JS30-230 type), and the centrifuge is Hunan Xiangli CTL550 type.

[0040] Preparation: Take 50g of dried anterior pituitary granules and crush them into solid powder with a mixer (25g of solid particles each time, stir for 3-5 minutes), and set aside for later use.

[0041] Activated D-101 macroporous resin, alcohol washing, water washing, acid washing, water washing, alkali washing, water washing, until the lotion is neutral and clear, soak in deionized water for use.

[0042] 1. Extraction: put the ground dry powder of anterior pituitary gland into a 3L three-necked bottle, connect a thermometer, add 1L of 1M / L HOAc aqueous solution, stir and wet and mix well, add dropwise 50% H 2 SO 4 The pH value of the solution adjustment system was 2.0. The reaction flask was placed on an oil bath, stirred and heated to make the internal temperature reach 80°C, maintained the ...

Embodiment 2

[0047] preparation of corticotropin

[0048] The equipment and preparation steps used in this example are the same as those in Example 1.

[0049] 1. Extraction: put the ground dry powder of the anterior pituitary gland into a 3L three-necked bottle, connect a thermometer, add 1L of 1M / L HOAc aqueous solution, stir, wet and mix well, add 50% H dropwise 2 SO 4 The pH value of the solution adjustment system is 2.5. The reaction flask was placed on an oil bath, stirred and heated to make the internal temperature reach 70°C, maintained the temperature, and kept stirring for 20 minutes for extraction. Then take out the oil bath, quench to 4°C, centrifuge (4000r / min, 5min), pour out the supernatant and combine to obtain the extract (stored at 15°C).

[0050] 2. Adsorption: Add 30g of activated D-101 macroporous resin to the extract obtained in the first step, and slowly stir and adsorb at 20°C for 10h, and the adsorption is completed. The adsorbed extract is filtered, and the ma...

Embodiment 3

[0054] preparation of corticotropin

[0055] The equipment and preparation steps used in this example are the same as those in Example 1.

[0056] 1. Extraction: put the ground dry powder of the anterior pituitary gland into a 3L three-necked bottle, connect a thermometer, add 1L of 1M / L HOAc aqueous solution, stir, wet and mix well, add 50% H dropwise 2 SO 4 The pH value of the solution adjustment system is 1. The reaction flask was placed on an oil bath, stirred and heated to make the internal temperature reach 75°C, maintained the temperature, and kept stirring for 20 minutes for extraction. Then the oil bath was taken out, quenched to 10°C, centrifuged (4000 r / min, 5min), the supernatant was poured out and combined to obtain the extract (stored at 10°C).

[0057] 2. Adsorption: Add 30g of activated D-101 macroporous resin to the extract obtained in the first step, and slowly stir and adsorb at 27°C for 15h, and the adsorption is completed. The adsorbed extract is filte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap