Method for circularly extracting protein and humus from residual sludge after dehydration by combining ultrasonic method with acid process

A technique of recycling and extracting excess sludge, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as inability to maximize resource utilization, poor biochemical performance, etc., with a short time to achieve and easy operation , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

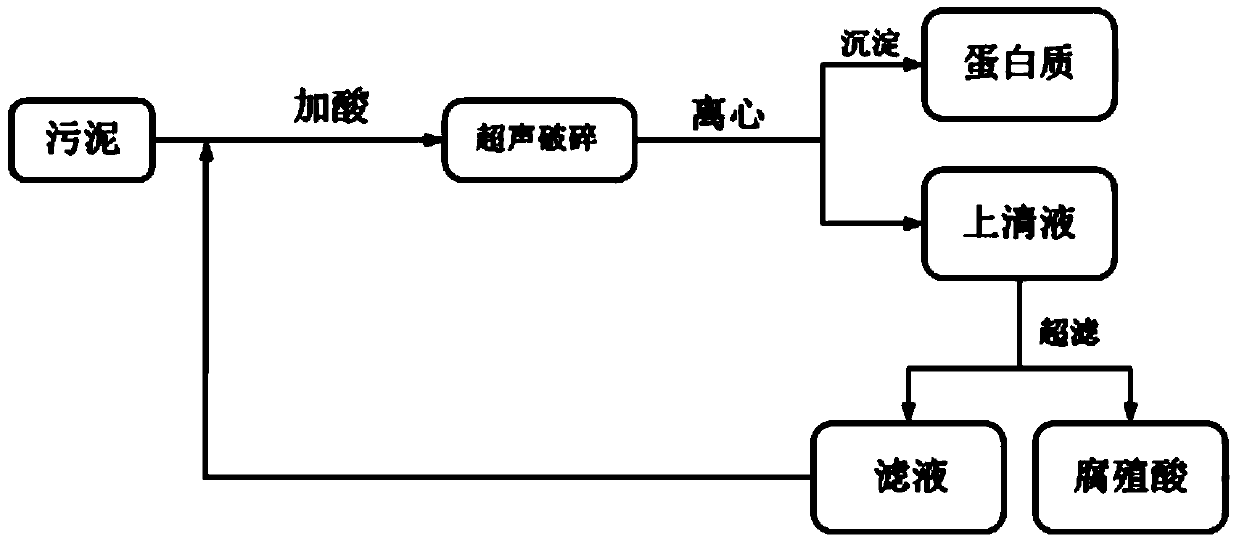

[0029] Embodiment 1: A method of utilizing ultrasonic method and acid method to extract protein and humus in dewatered excess sludge in this embodiment is carried out according to the following steps:

[0030] 1. Ultrasonic cracking of the dehydrated excess sludge of urban sewage treatment plants under acidic conditions: adjust the excess sludge of urban sewage treatment plants to a pH of 1 to 3 with sulfuric acid at a concentration of 2mol / L, at a frequency of 20KHz, power density Crumble in a 1-2W / mL ultrasonic breaker for 10-30 minutes, then pass through a 100-mesh sieve to remove solid particulate matter on the sieve to obtain a lysate;

[0031] 2. Static precipitation promotes protein precipitation: the lysate is statically settled at room temperature for 30-60 minutes, so that the cracked protein is precipitated under acidic conditions;

[0032] 3. Extract protein by centrifugation: centrifuge the lysed solution after settling in a centrifuge at a temperature of 4-30°C a...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pH in step 1 is 2. Others are the same as in the first embodiment.

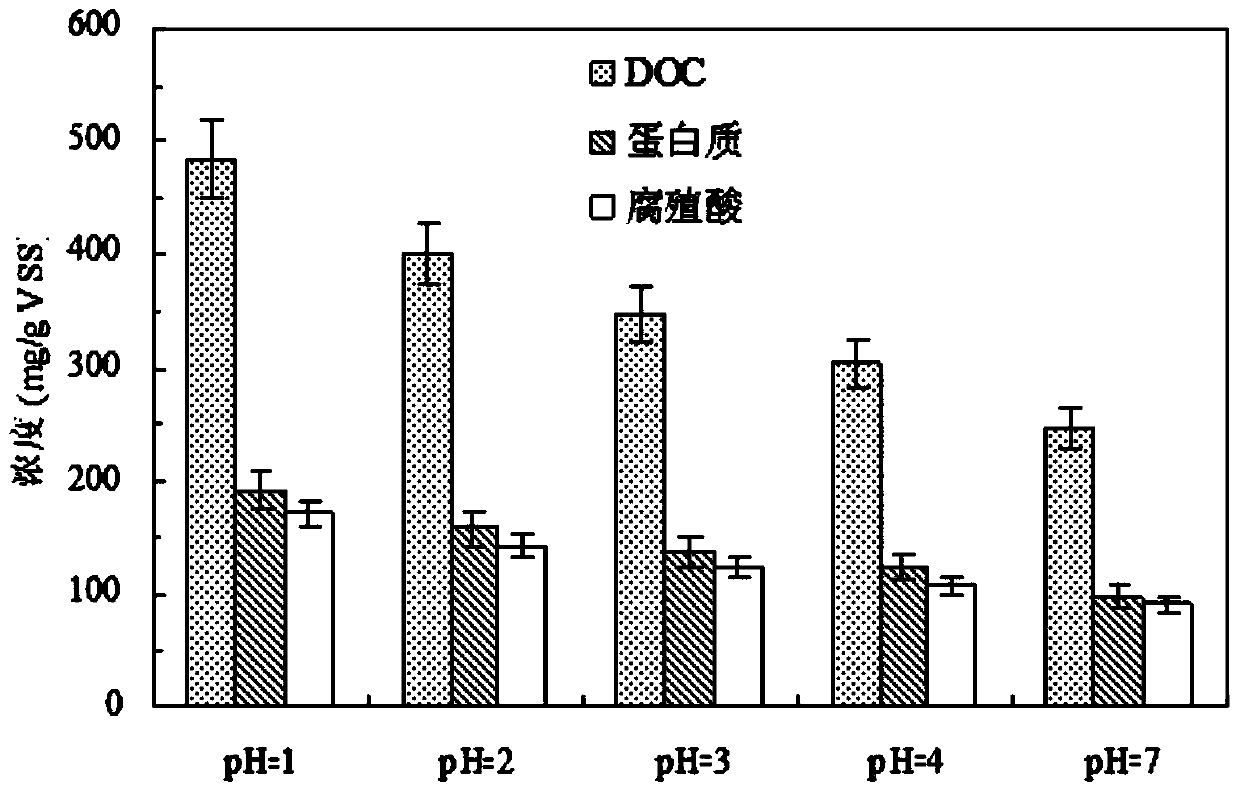

[0037]In this embodiment, 2mol / L sulfuric acid is used to adjust to different pH values, the pH is 1, 2, and 3, and then ultrasonically treated, and the lysate is taken for detection. When the pH is 1, 2, and 3, the protein recovery rate is 75 %, but when the pH of the solution is equal to 3, the recovery rate of humic substances is only 57.8%. Considering the economic benefit and crushing effect, pH=2 is the optimum pH value.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the power density in step 1 is 1.5 W / mL. Others are the same as in the first or second embodiment.

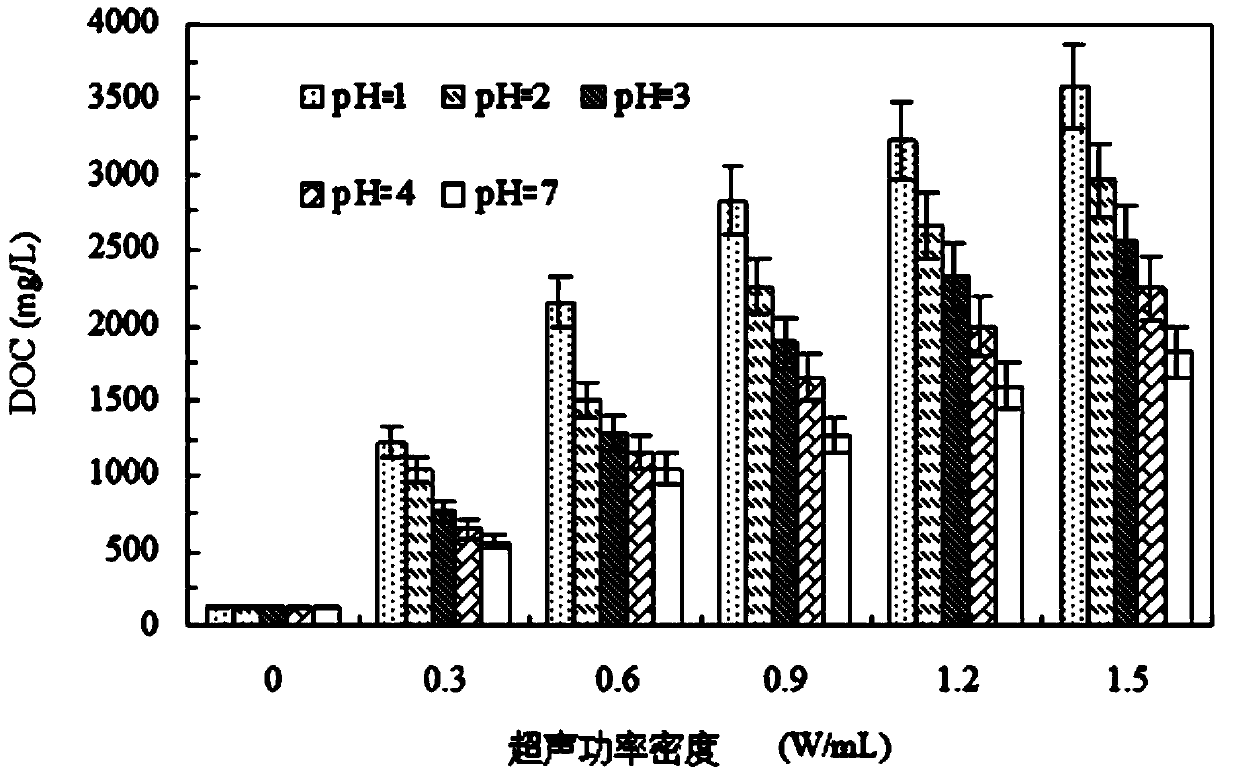

[0039] The sludge of this embodiment is ultrasonically treated under different ultrasonic power densities and different pHs, and the content of dissolved organic carbon (DOC) in the lysate is measured after ultrasonication. The results show that: under the same pH value, when the ultrasonic power When the density increased from 0W / mL to 1.5W / mL, the concentration of DOC in the lysate gradually increased, and then with the increase of ultrasonic power density, the dissolution and removal of DOC was gentle, so when the ultrasonic power density was 1.5W / mL Works best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com