Alignment method, alignmenet apparatus, vacuum evaporation method and vacuum evaporation apparatus

A technology for alignment marks and detection methods, applied in vacuum evaporation coating, measuring devices, using optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

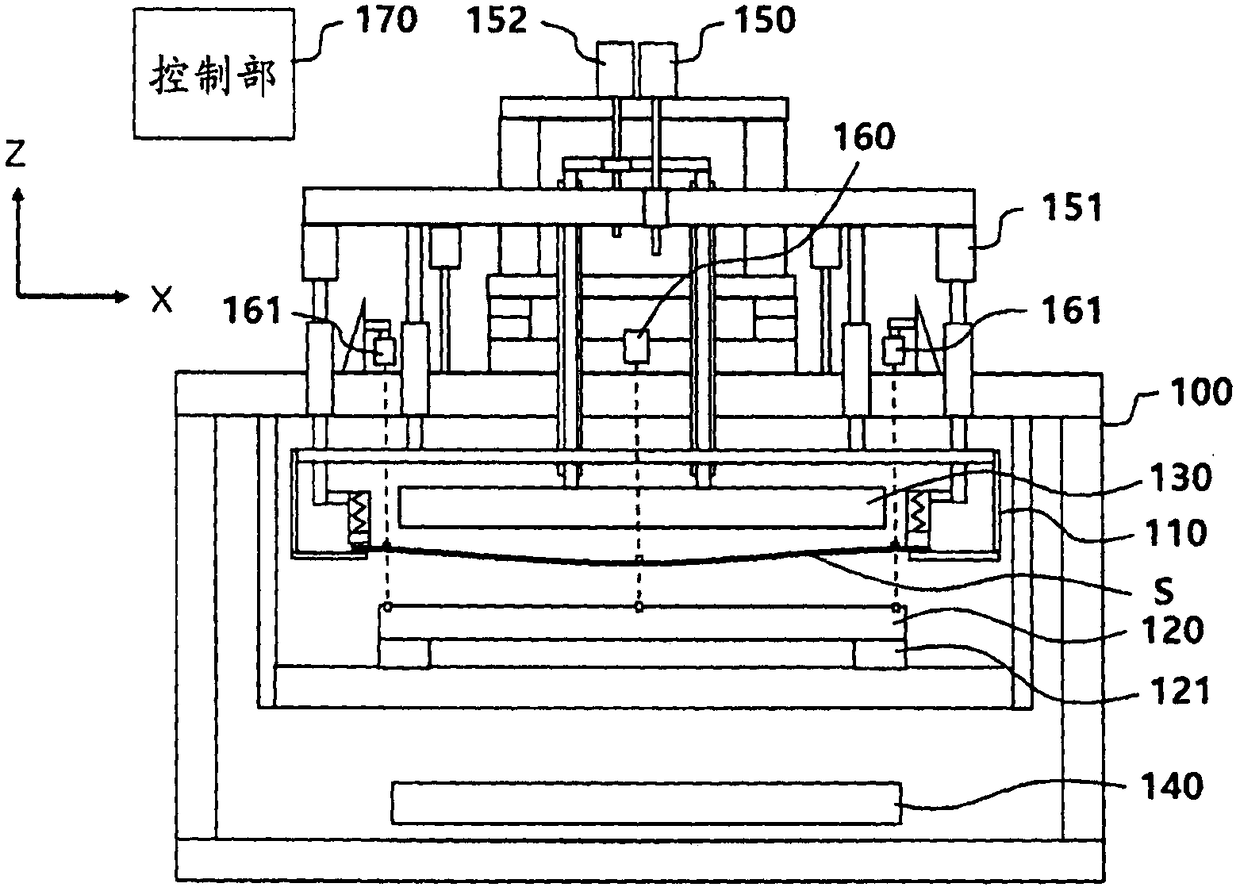

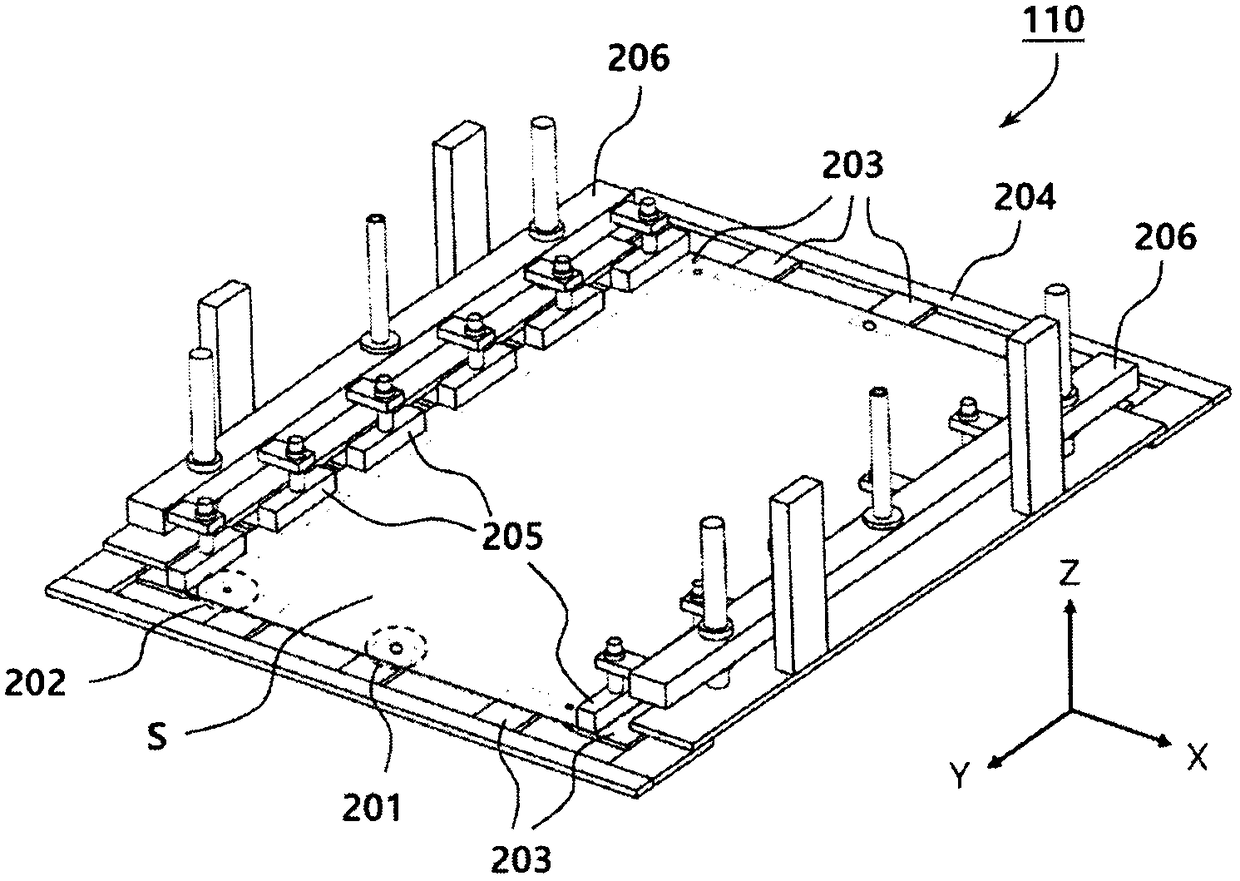

[0031] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The present invention can be modified variously, and can have various embodiments. Although specific examples are illustrated based on the drawings, the present invention is not limited to the specific examples, and it should be understood that all changes, equivalents, and substitutions included in the spirit and scope of the present invention are included.

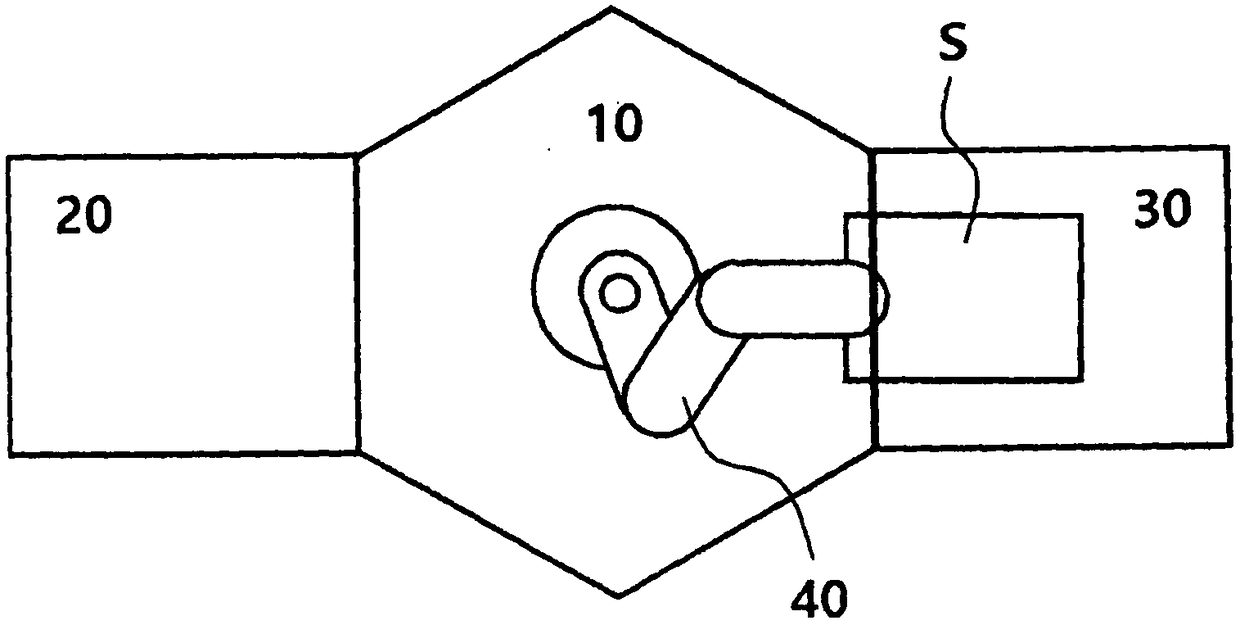

[0032]The present invention relates to a film forming apparatus for forming a thin film on a substrate and a control method thereof, and particularly relates to a technology for high-precision conveyance and position adjustment of a substrate. The present invention can be preferably applied to an apparatus for forming a thin film (material layer) of a desired pattern by vacuum evaporation on the surface of a parallel plate substrate. Also, any material such as glass, resin, or metal can be selected as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com