Invisible fluorescent white dye transfer printing method of thermal sublimation cloth

A thermal sublimation, thermal transfer technology, applied in transfer printing, dyeing, printing and other directions, can solve the problem of inability to have the characteristics of disperse dyes, and achieve the effect of convenient operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

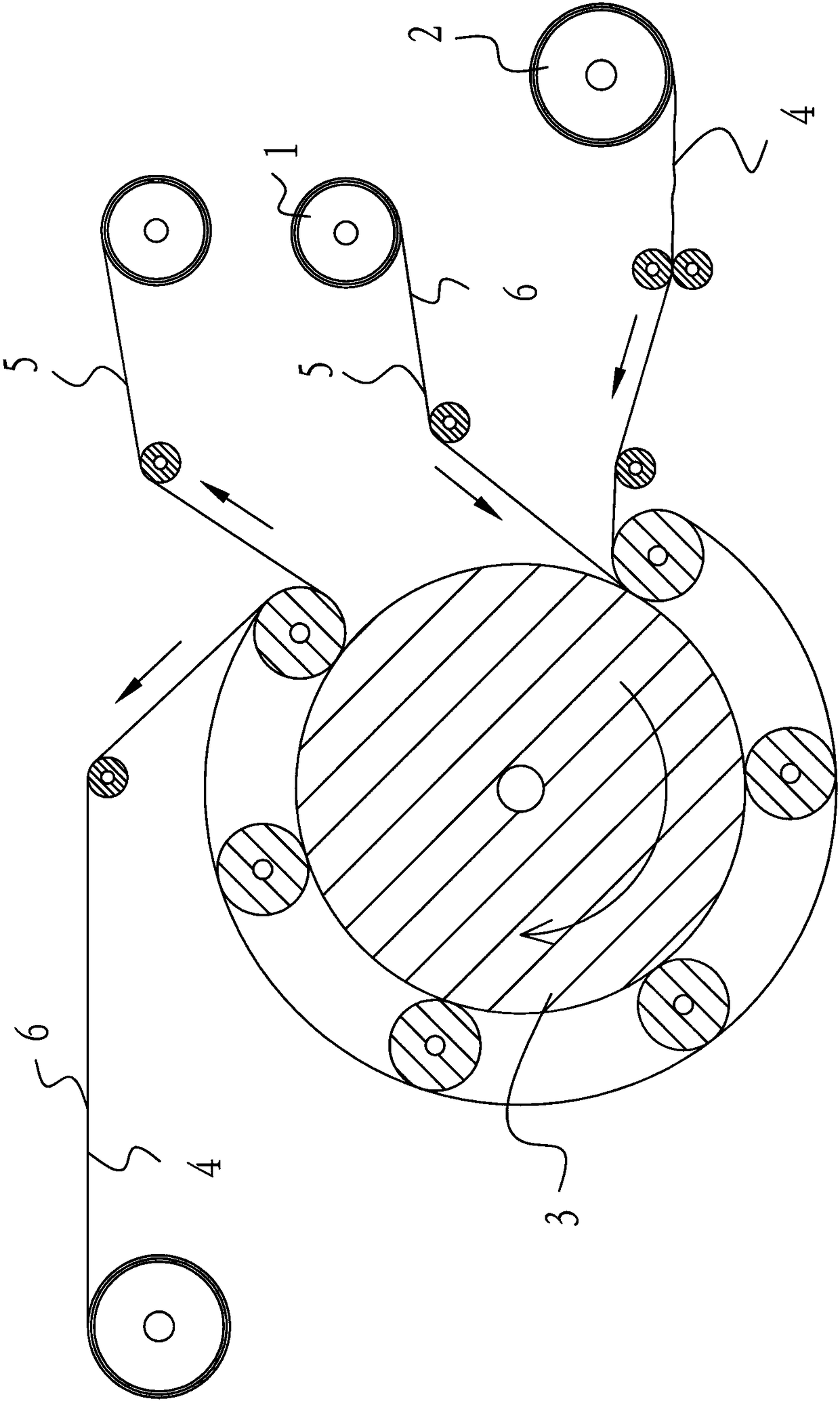

Image

Examples

Embodiment Construction

[0018] In order to achieve the above-mentioned purpose and effect, the technical means and the structure adopted by the present invention are hereby described in detail with respect to the preferred embodiments of the present invention.

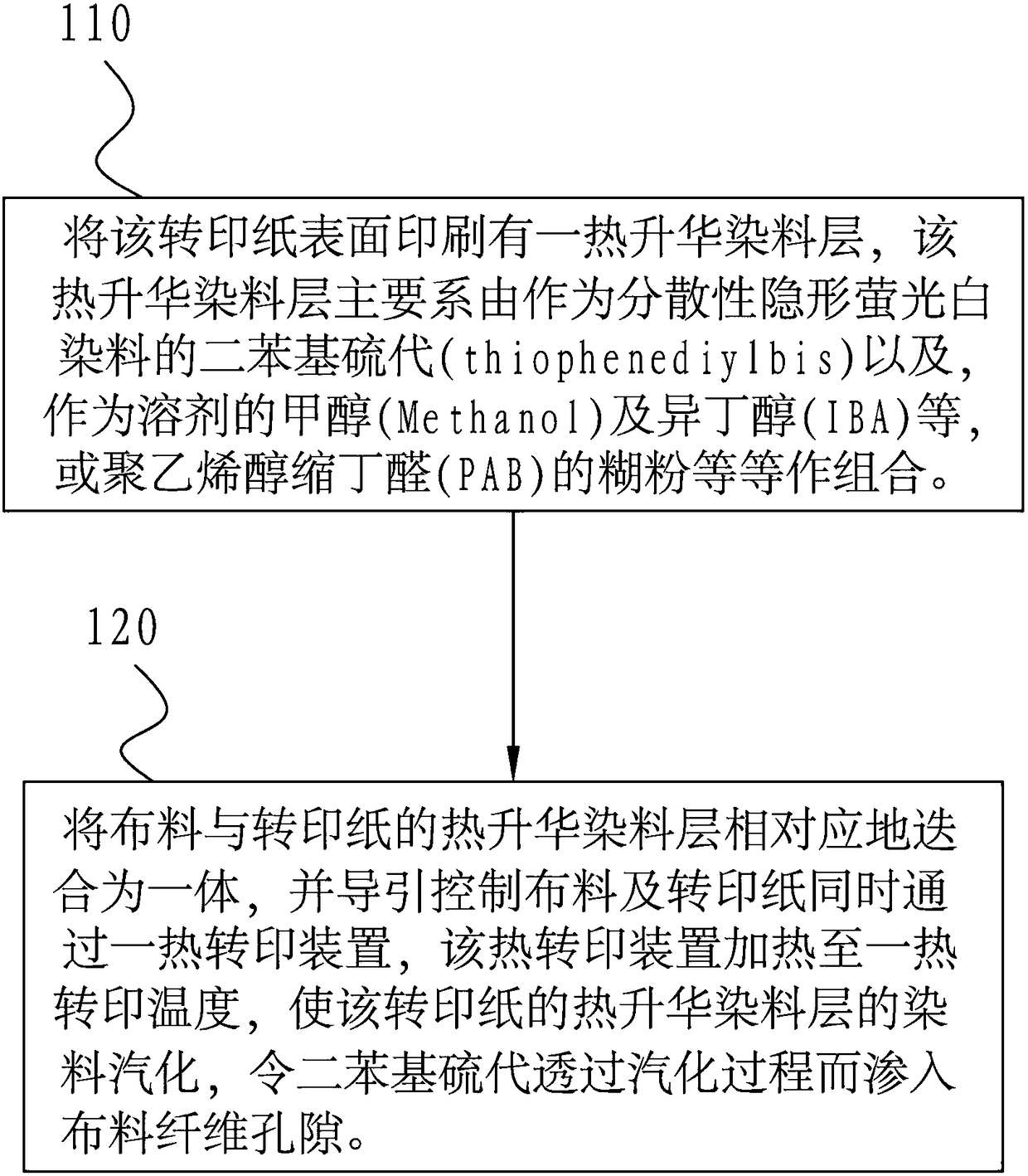

[0019] see figure 2 , figure 2 It is a schematic flow chart of the thermal sublimation transfer method of the present invention.

[0020] Such as figure 2 As shown, the present invention provides a method for transferring invisible fluorescent white dye to sublimation cloth, which method at least includes: a thermal transfer heating device, a cloth, and a transfer paper equivalent in length to the cloth. Proceed as follows:

[0021] Step 110: Printing a thermal sublimation dye layer on the surface of the transfer paper, the thermal sublimation dye layer is mainly composed of thiophenediylbis as a dispersible invisible fluorescent white dye and methanol (Methanol) as a solvent and isobutanol (IBA), etc., or aleurone of polyvinyl butyral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com