Self-stabilizing floating type temporary breakwater structure

A breakwater and temporary technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve the problems of limited energy dissipation effect of floating breakwaters, difficulty in driving and pulling piles, and high foundation cost, and achieve significant wave dissipation effect, light weight, and anti-skid Enhanced performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

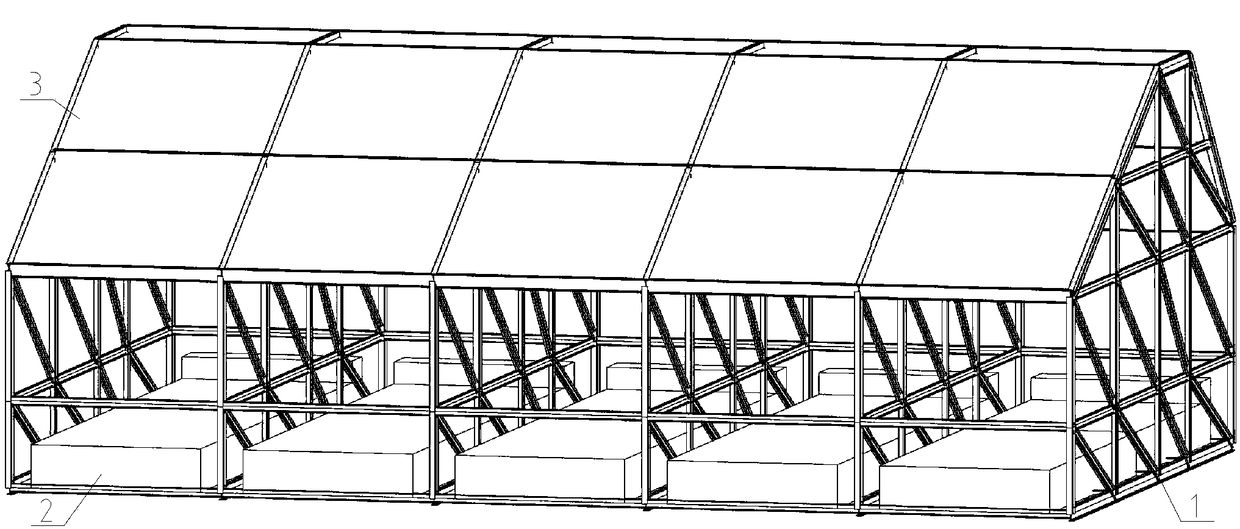

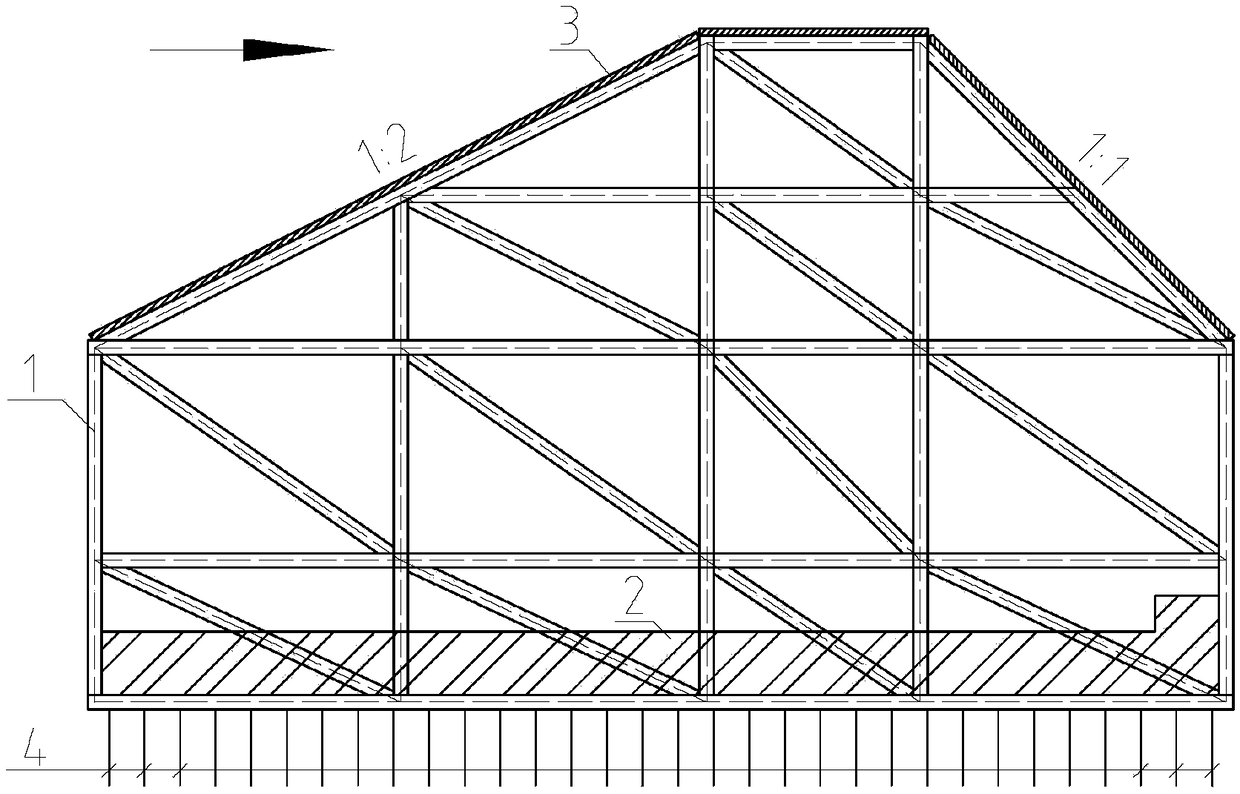

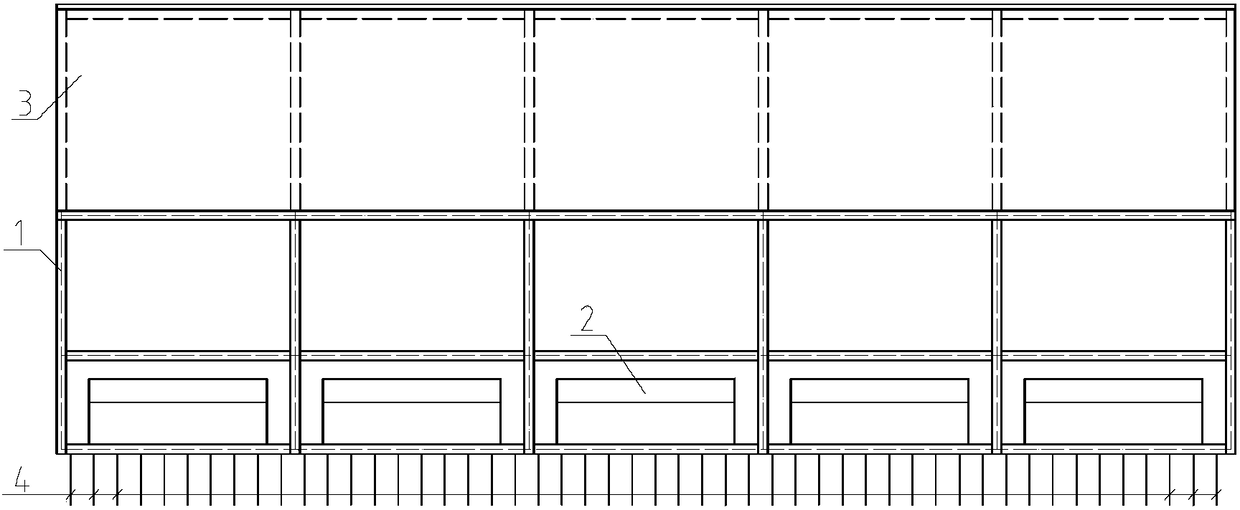

[0027] Referring to the drawings for details, this embodiment provides a self-stabilizing floating temporary breakwater structure, including a structural frame, a steel buoy box 2, a raised balance buoy box 5, planks 3, and anti-skid steel bars 4. figure 2 , Figure 4 The middle arrow indicates the direction of the incoming wave.

[0028] The structural frame is formed by connecting multiple steel structure trusses 1 through section steel, and each steel structure truss 1 is composed of multiple vertical support section steels, horizontal support section steels and oblique support section steels. The top wave surface and the back wave surface of the structural frame are both slope surfaces. The steel buoy box with submersible pump and air intake pipe inside is welded at the lower part, and the anti-skid steel bar is welded at the bottom. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com