Facing brick veneering splicing structure and construction method thereof

A construction method and technology for facing bricks, which are applied in the directions of floors, adhesives, building structures, etc., can solve the problems of facing bricks lifting or even peeling off, cracking of hardened bonding layers, and damage to structural strength, etc., so as to ensure the overall construction quality, The effect of strengthening stability and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

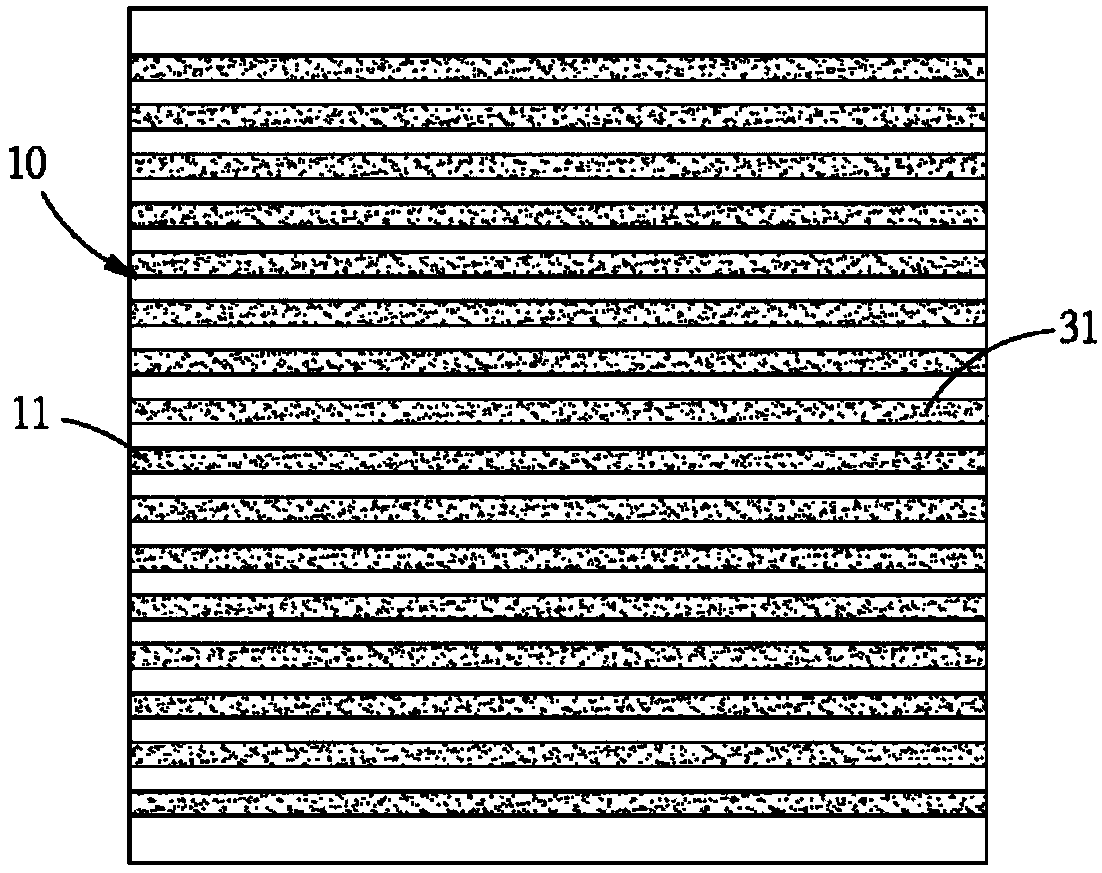

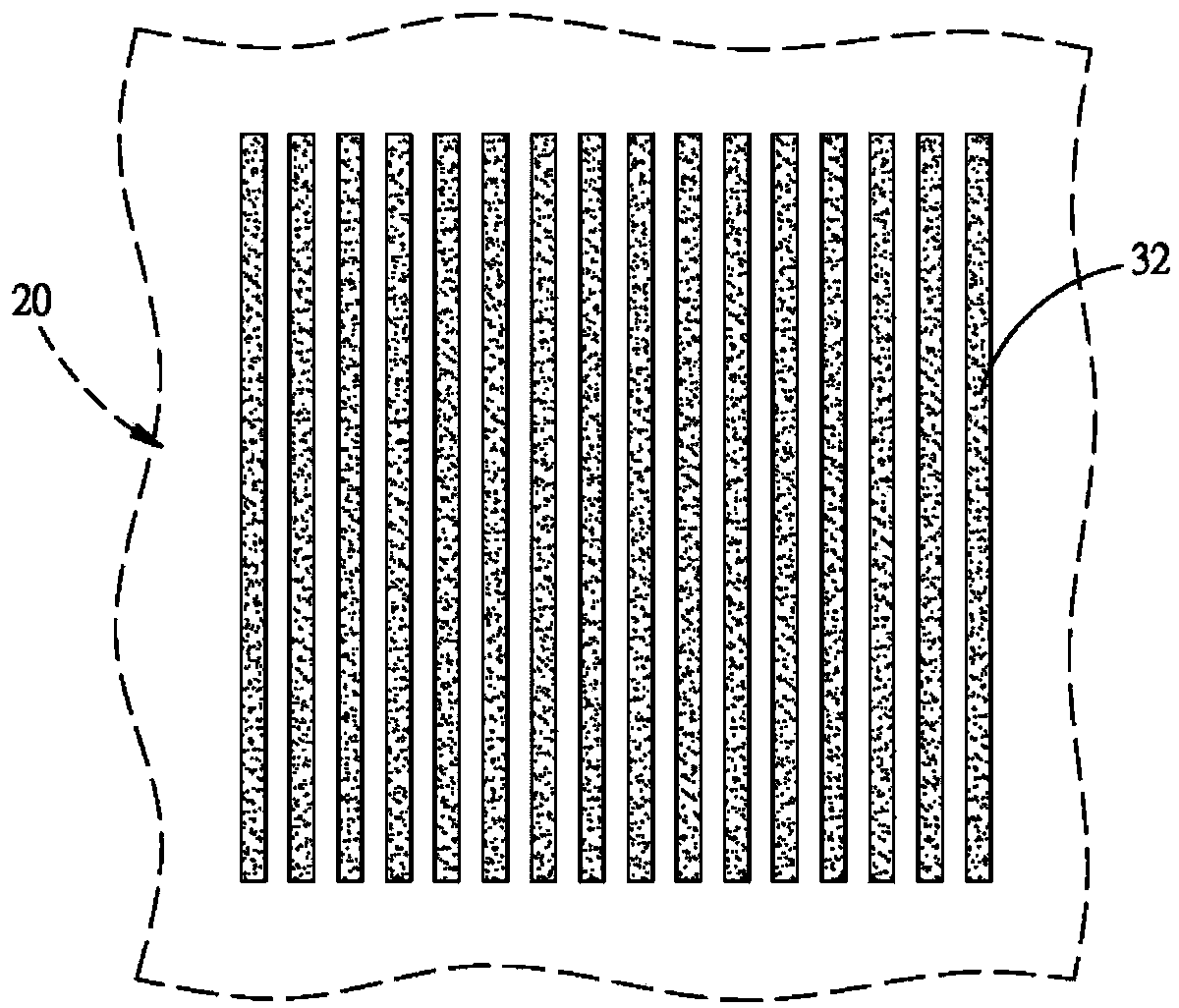

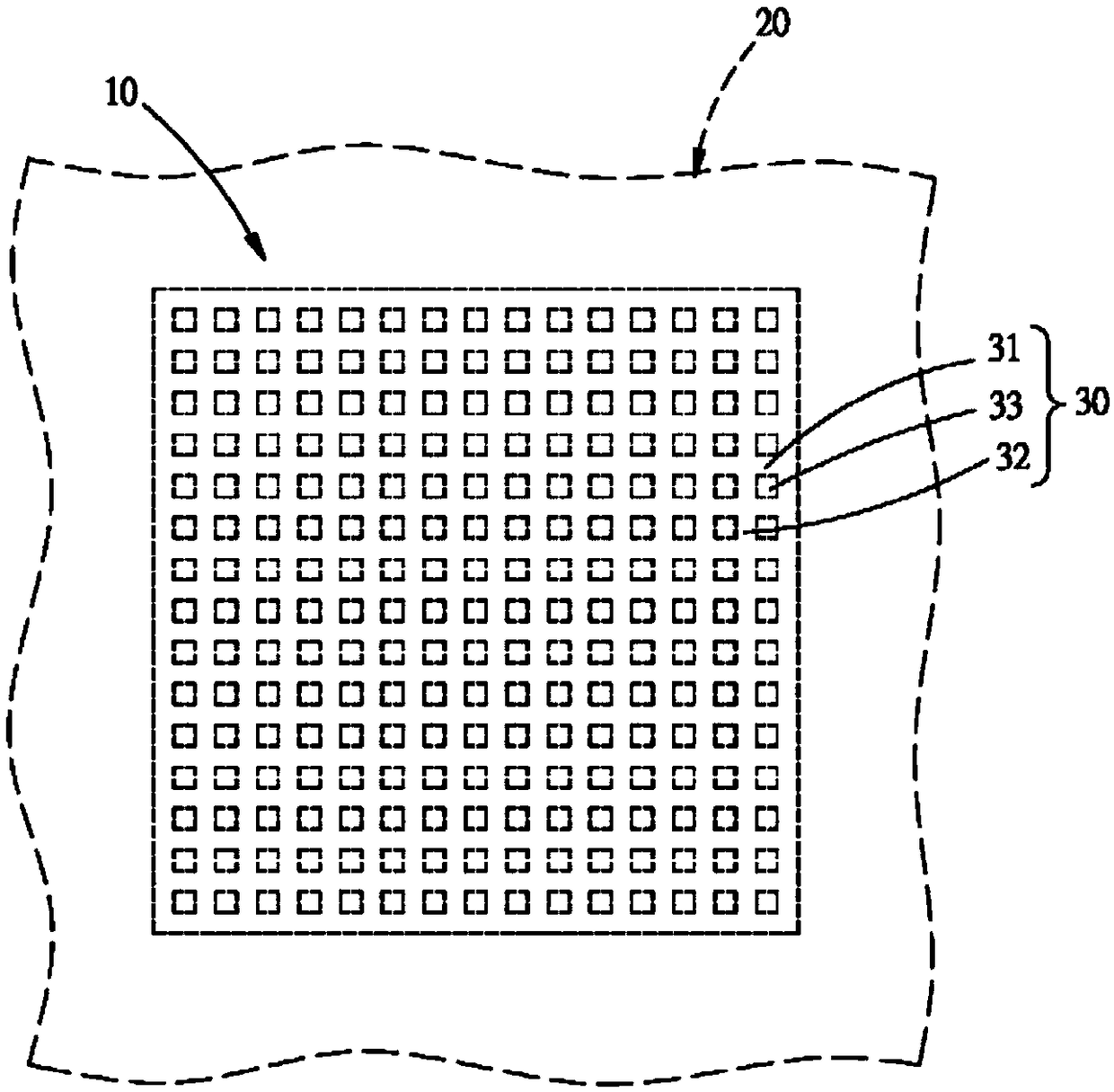

[0034] see Figure 1 to Figure 4 , the present invention provides a tile veneer bonding structure and a construction method thereof, which are used to bond the veneer 11 of the tile 10 to the paving surface 20 of the building through the bonding structure 30 . Wherein, the facing bricks 10 include facing bricks arranged on the ground, walls, and walls, and the materials of the facing bricks 10 include stone, vitrified bricks, etc., but are not limited to the foregoing.

[0035] Among them, such as figure 1 , figure 2 , image 3 As shown, the bonding structure 30 is a network layer structure formed by interlacing the first cement mortar strips 31 and the second cement mortar strips 32 . Such as figure 1 As shown, the first cement mortar strip 31 is coated and formed on the veneer 11 of the tile 10 along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com