Sizing agent soaking detection method

A detection method and sizing agent technology, applied in the field of sizing agent immersion detection, can solve problems affecting normal production and high test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

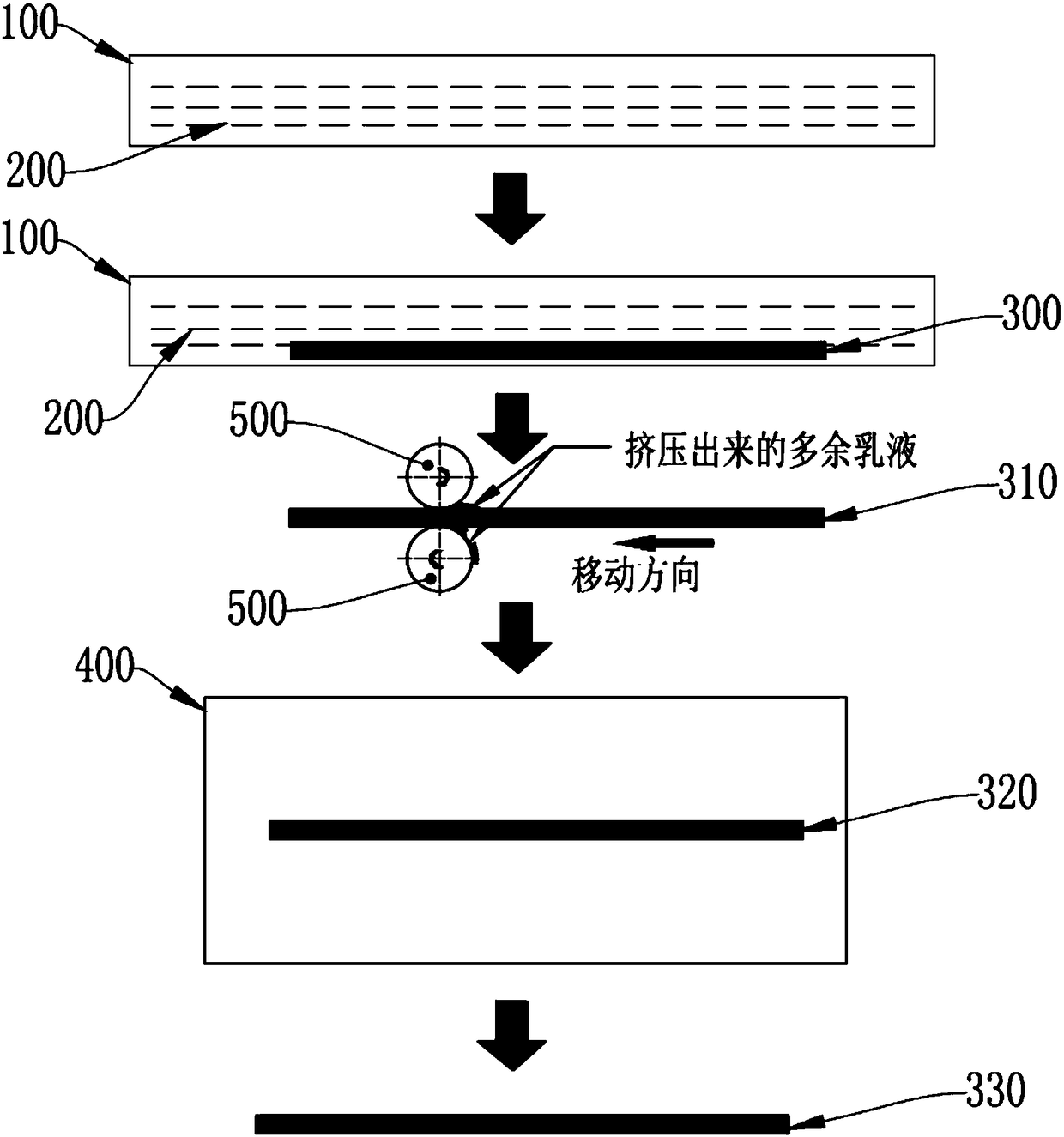

Image

Examples

Embodiment 1

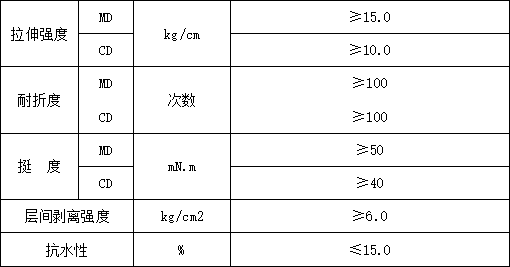

[0060] Detection of the sizing agent to be tested

[0061] The difference between this embodiment and the detection of the above-mentioned first standard sizing agent is that the above-mentioned standard sizing agent is replaced with the sizing agent to be detected. The formula of the sizing agent to be detected in this embodiment is: Rosin gum. Finally, the detection data of this embodiment are shown in the following table:

[0062] The detection data of table 2 embodiment 1

[0063]

[0064] Comparing the test data in this table with the standard range data in Table 1, it can be concluded that the sizing agent formula in this example is not suitable for the production of fiberboard.

Embodiment 2

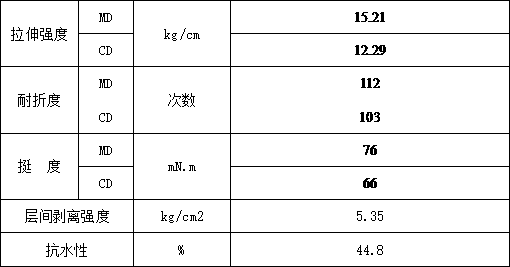

[0066] Detection of the sizing agent to be tested

[0067] The difference between this embodiment and the detection of the above-mentioned second standard sizing agent is that the above-mentioned standard sizing agent is replaced with the sizing agent to be detected. The formula of the sizing agent to be detected in this embodiment is: paraffin wax produced by a certain company Emulsion sizing agent. Finally, the detection data of this embodiment are shown in the following table:

[0068] The detection data of table 3 embodiment 2

[0069]

[0070] Comparing the test data in this table with the standard range data in Table 1, it can be concluded that the sizing agent formula in this example is suitable for the production of fiberboard.

Embodiment 3

[0072] Detection of the sizing agent to be tested

[0073] The difference between this embodiment and the detection of the above-mentioned third standard sizing agent is that the above-mentioned standard sizing agent is replaced with the sizing agent to be detected. The formula of the sizing agent to be detected in this embodiment is: a modified permanent starch. Finally, the detection data of this embodiment are shown in the following table:

[0074] The detection data of table 4 embodiment 1

[0075]

[0076] Comparing the test data in this table with the standard range data in Table 1, it can be concluded that the sizing agent formula in this example is suitable for the production of fiberboard.

[0077] As can be seen from the above, the sizing agent immersion detection method is to imitate the actual production situation, the board to be tested is produced, and finally according to the existing cardboard performance detection method, the performance data of the board...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com