Processing method for manufacturing fuse holder, fuse holder and fuse

A processing method and technology of fuse holders, which are applied in processing and manufacturing, additive processing, fuse manufacturing, etc., can solve problems such as high cost, high logistics consumption, and various types, and achieve improved strength, reduced material cost, and small weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

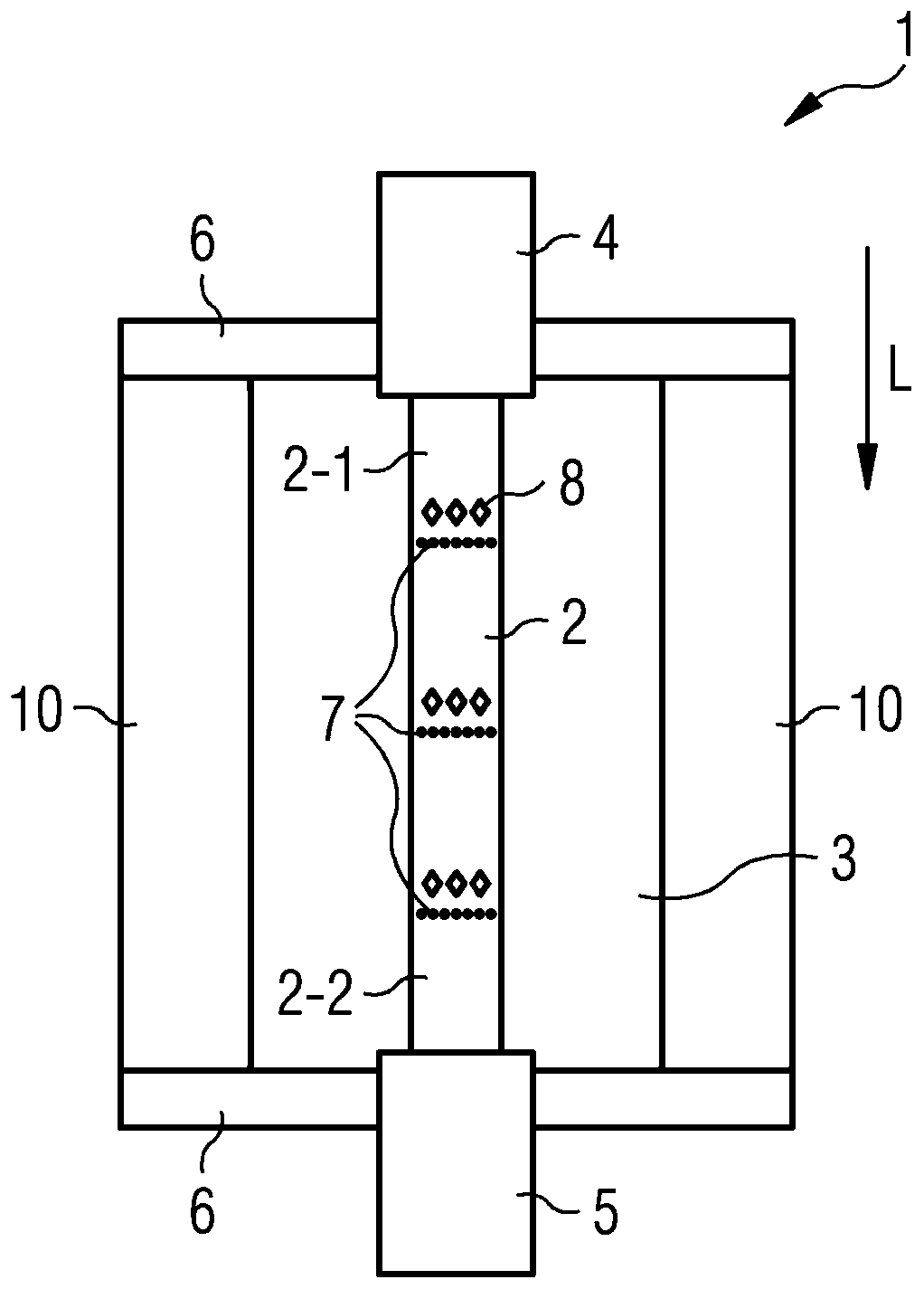

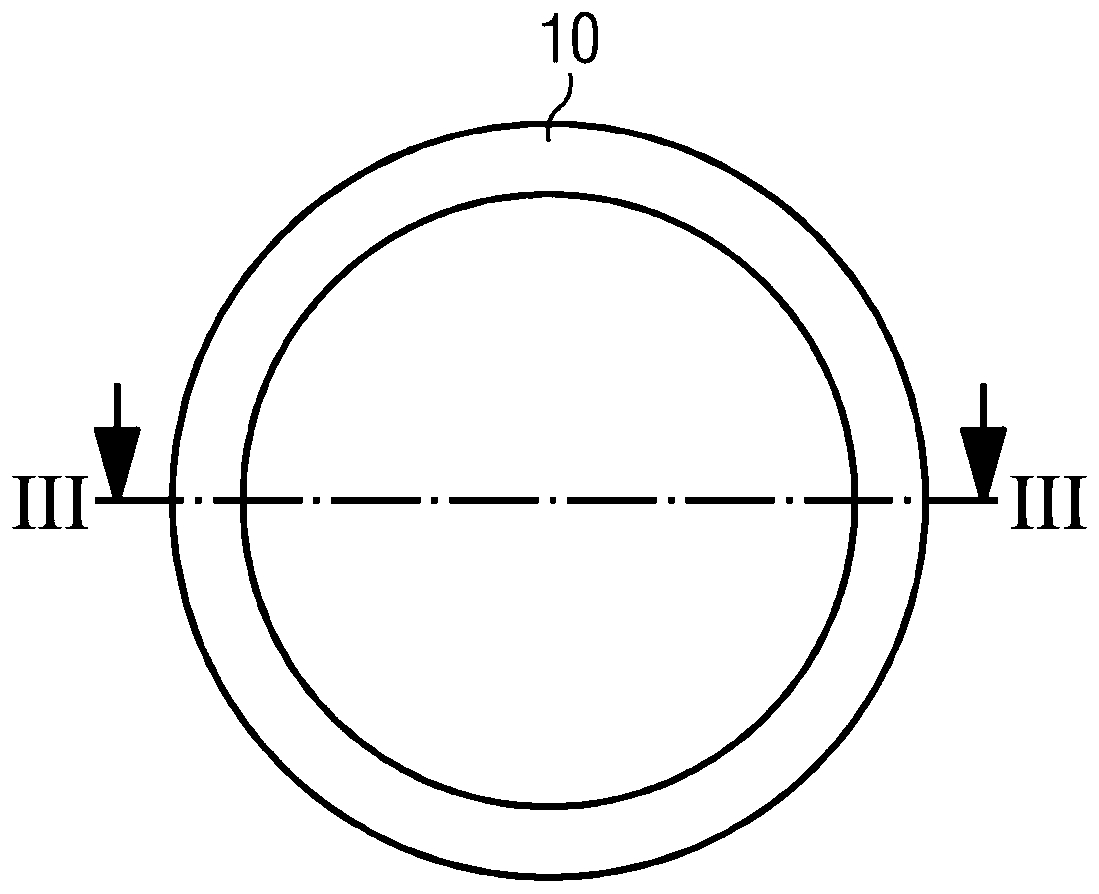

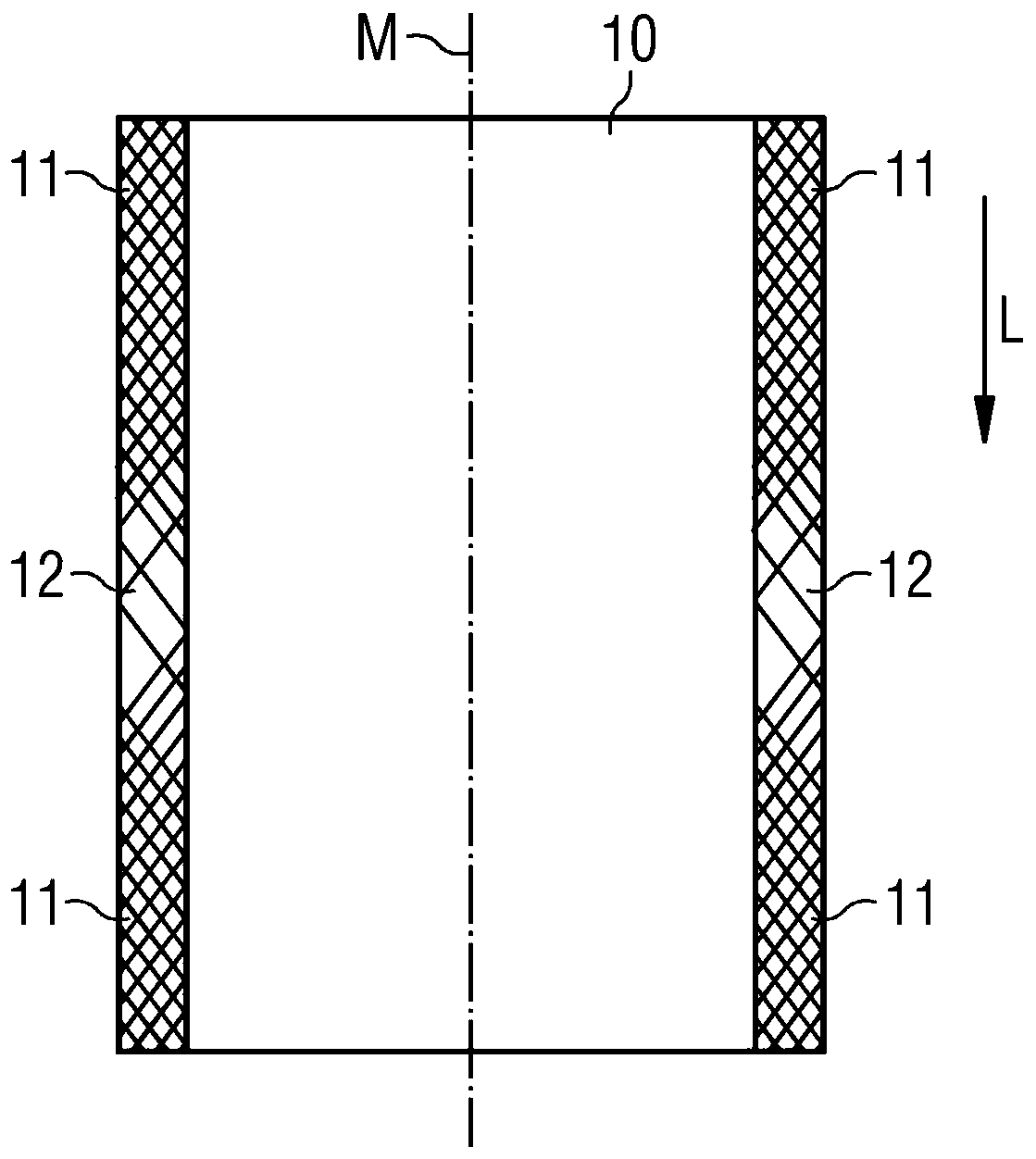

[0032] figure 1 A schematic diagram showing the basic construction of the fuse 1 . The fuse 1 has a first contact element 4 and a second contact element 5 , both of which are made of an electrically conductive material, for example copper. The contact elements 4 and 5 are mechanically fixed and hermetically sealed or tightly connected to a fuseholder 10 , which consists of a solid, non-conductive and as high temperature-resistant material as possible, for example ceramic. The fuse holder 10 generally has a tubular basic shape and is closed pressure-tight to the outside, for example by means of two closure caps 6 . The contact elements 4 and 5 each extend here into the interior of the fuseholder 10 through an opening formed in the closure cover 6 . Arranged in this interior is a so-called fuse 2 which electrically conductively connects the first contact element 4 and the second contact element 5 . To this end, the first end 2 - 1 of the fuse 2 is electrically conductively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com