Laser annealing apparatus and sheet resistance calculation apparatus

A technology of surface resistance and laser annealing, which is applied in the direction of measuring devices, circuits, measuring electronics, etc., can solve problems such as time-consuming and labor-intensive damage to semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

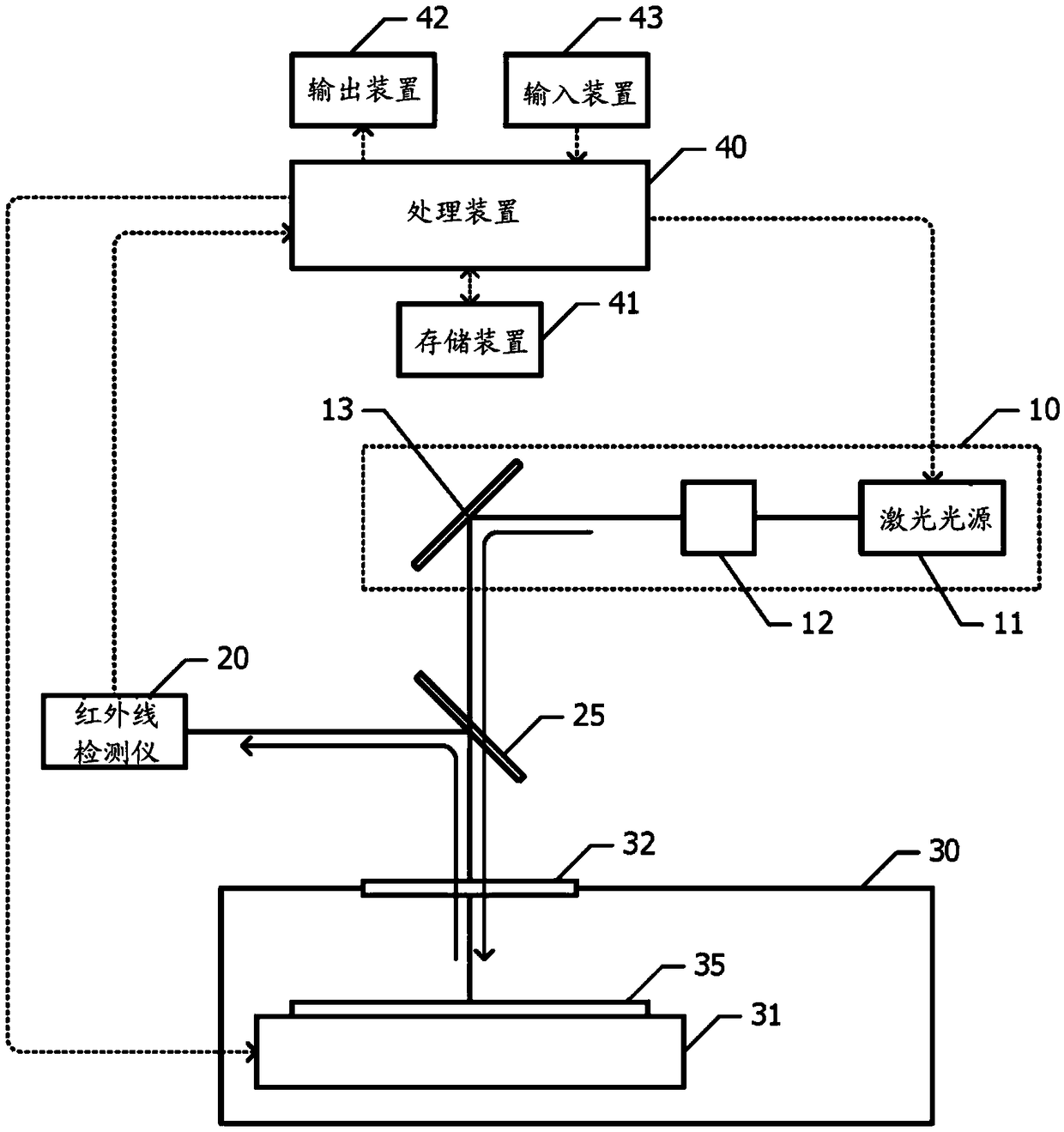

[0022] Below, refer to Figure 1 ~ Figure 5C , the laser annealing apparatus based on the embodiment will be described.

[0023] figure 1 It is a schematic diagram of the laser annealing apparatus based on an Example. The laser annealing device based on the embodiment includes a laser optical system 10 , a chamber 30 , an infrared detector 20 , a processing device 40 , a storage device 41 , an output device 42 and an input device 43 .

[0024] The laser optical system 10 includes a laser light source 11 , a homogenizing optical system 12 and a turning mirror 13 . The laser light source 11 outputs a laser beam in an infrared region. As the laser light source 11, for example, a laser diode with an oscillation wavelength of 808 nm can be used. The homogenizing optical system 12 homogenizes the beam distribution of the laser beam output from the laser light source 11 . The turning mirror 13 reflects the laser beam passing through the homogenizing optical system 12 downward. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com