Honeycomb frame edging inner face clamp

A hive frame and edge technology, which is applied in beehives, beekeeping, applications, etc., can solve the problem that honeycomb frames cannot be recycled to obtain honey.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

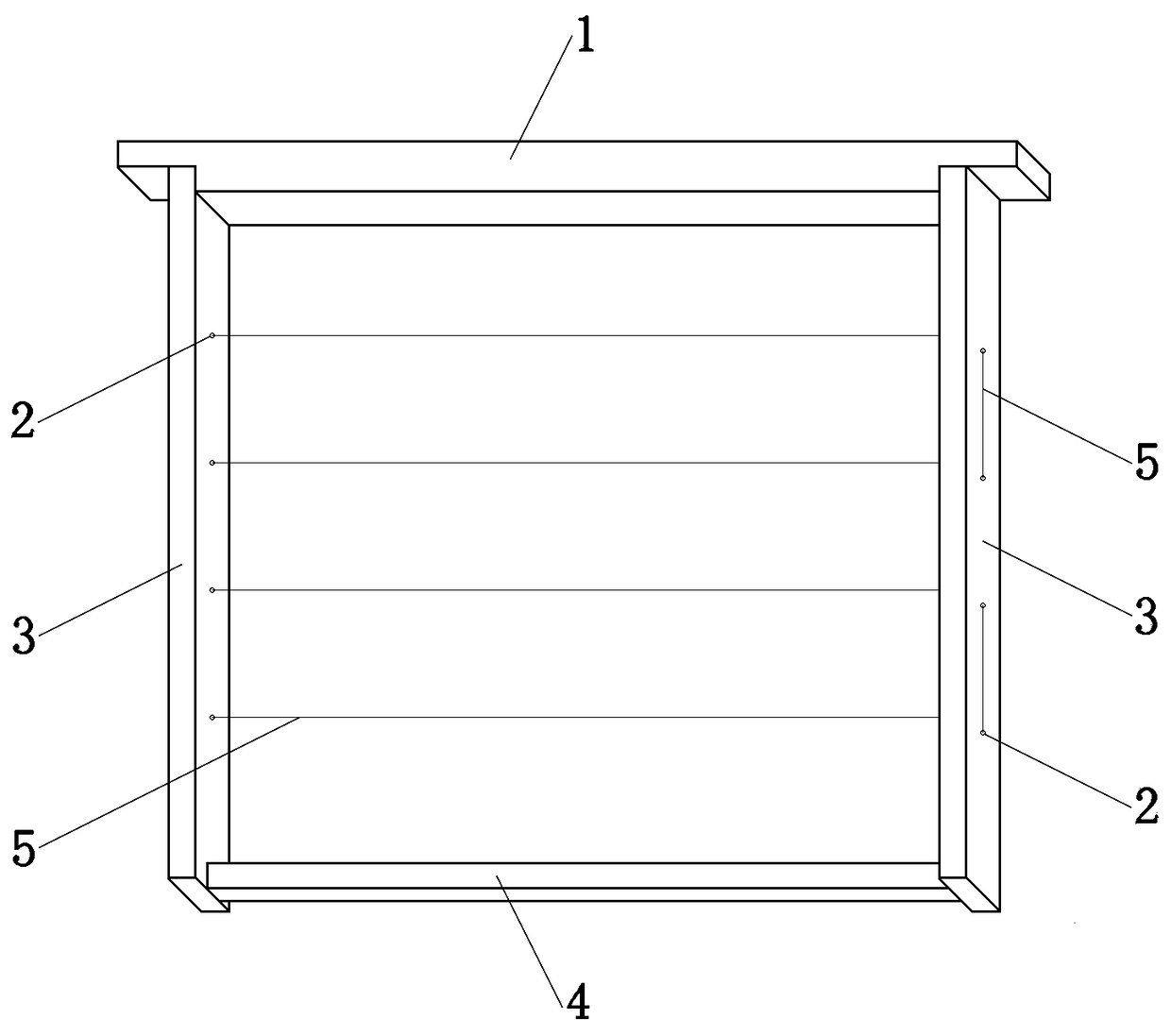

[0019] exist figure 1 Among them, the structure of the existing nest frame is: a nest frame upper beam 1, two nest frame side bars 3 with a plurality of threading holes 2 on the center line, and a nest frame lower beam 4 are combined to form a slightly smaller than Empty boxes inside beehives. During use, a plurality of metal wires 5 are horizontally arranged in the frame through the threading holes 2 on the frame side strips 3, and the honeybees build a honeycomb on the wire 5.

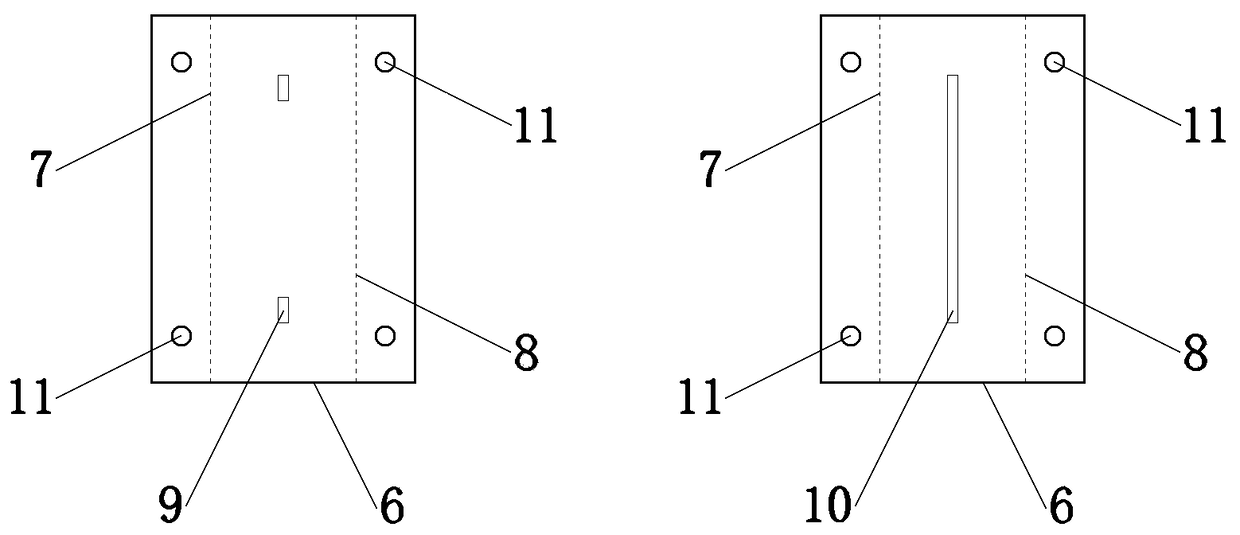

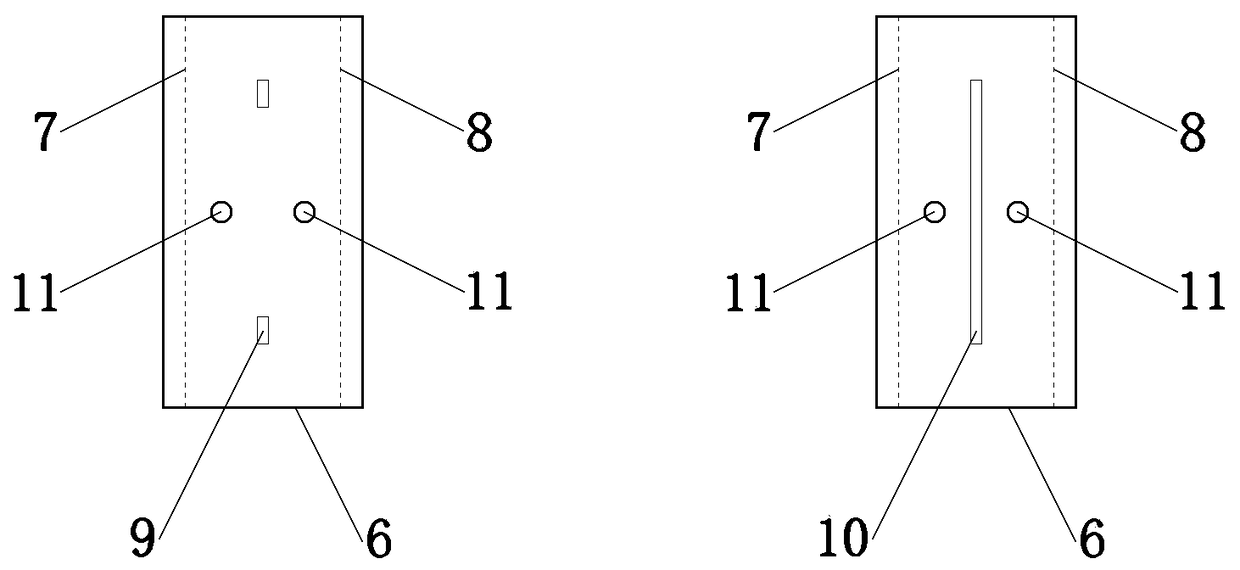

[0020] exist figure 2 As shown in the expanded view, it is on the left side of a metal plate 6 with a thickness of 0.6-1.2 mm, a length of 55-85 mm, and a width of 39-54 mm. There is a vertical left bending line 7 on the right side of the metal plate 6. , there is one longitudinal right bending line 8; the distance from the left bending line 7 to the edge of the left sheet metal 6 is 8-13 mm, the distance from the right bending line 8 to the edge of the right sheet metal 6 is 8-13 mm, and the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com