Bean grinding and peeling device

A technology for grinding beans and bean curds, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of affecting the taste of food, doping with bean curds, etc., and achieve the effect of shortening working time, speeding up the speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

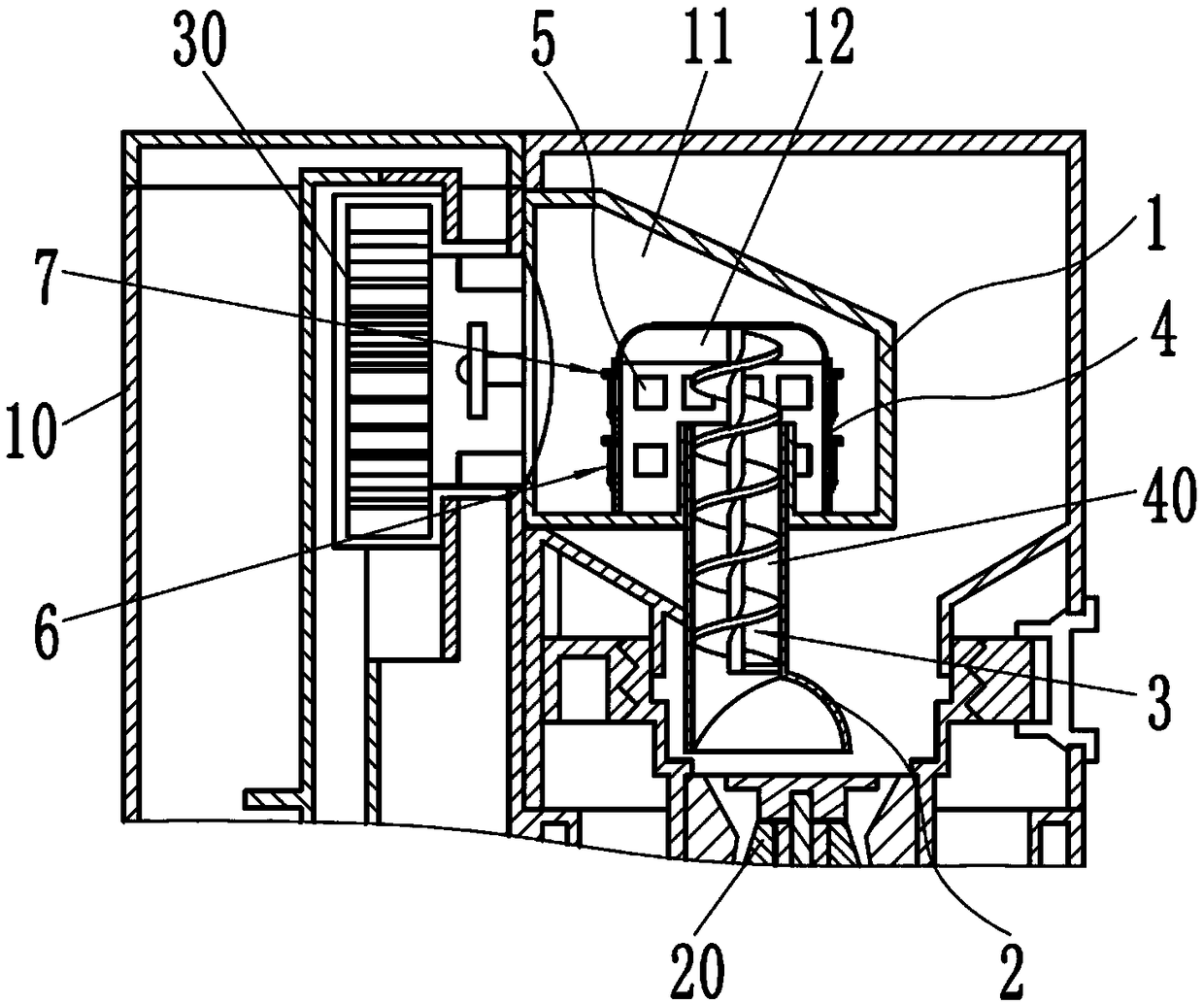

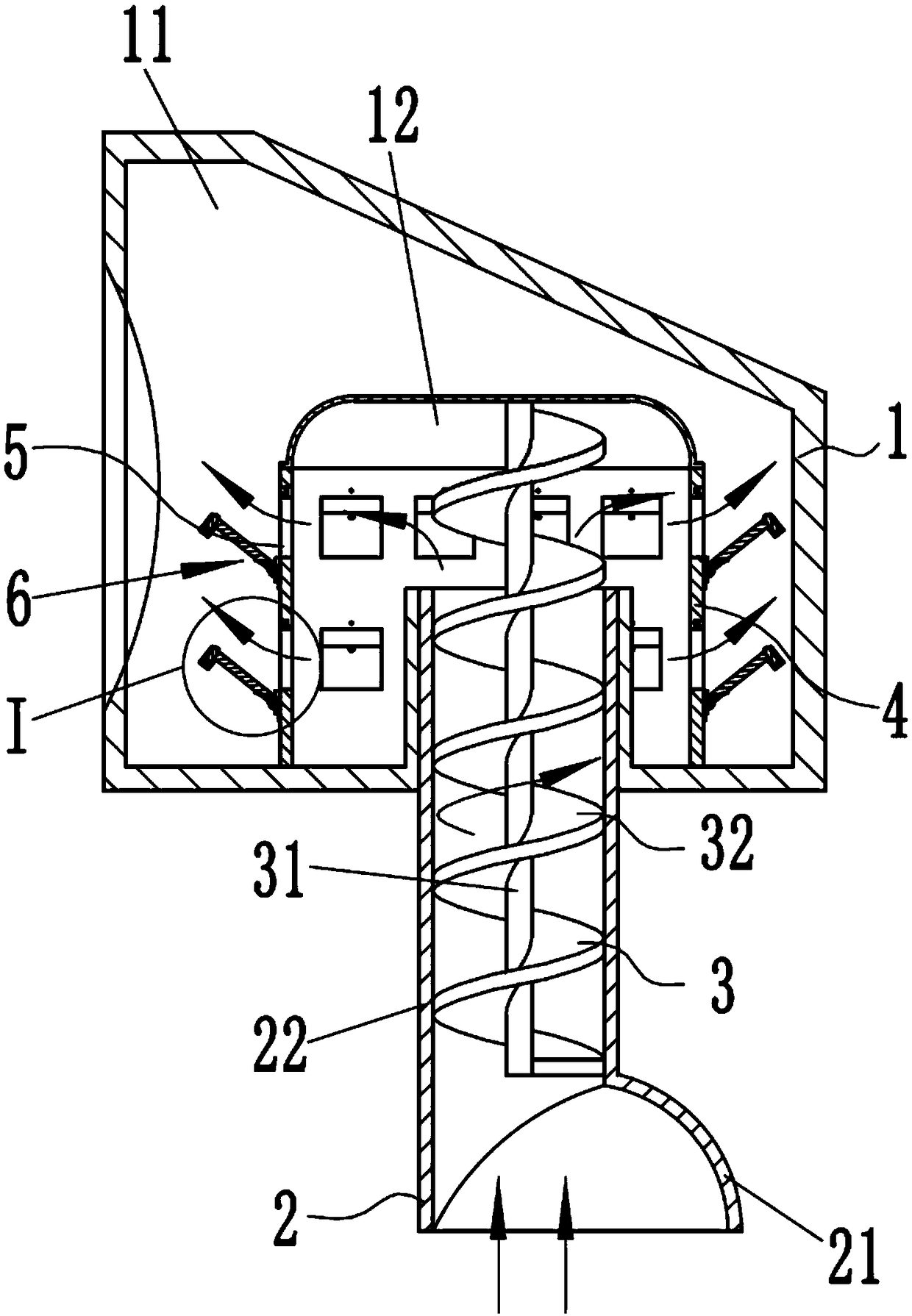

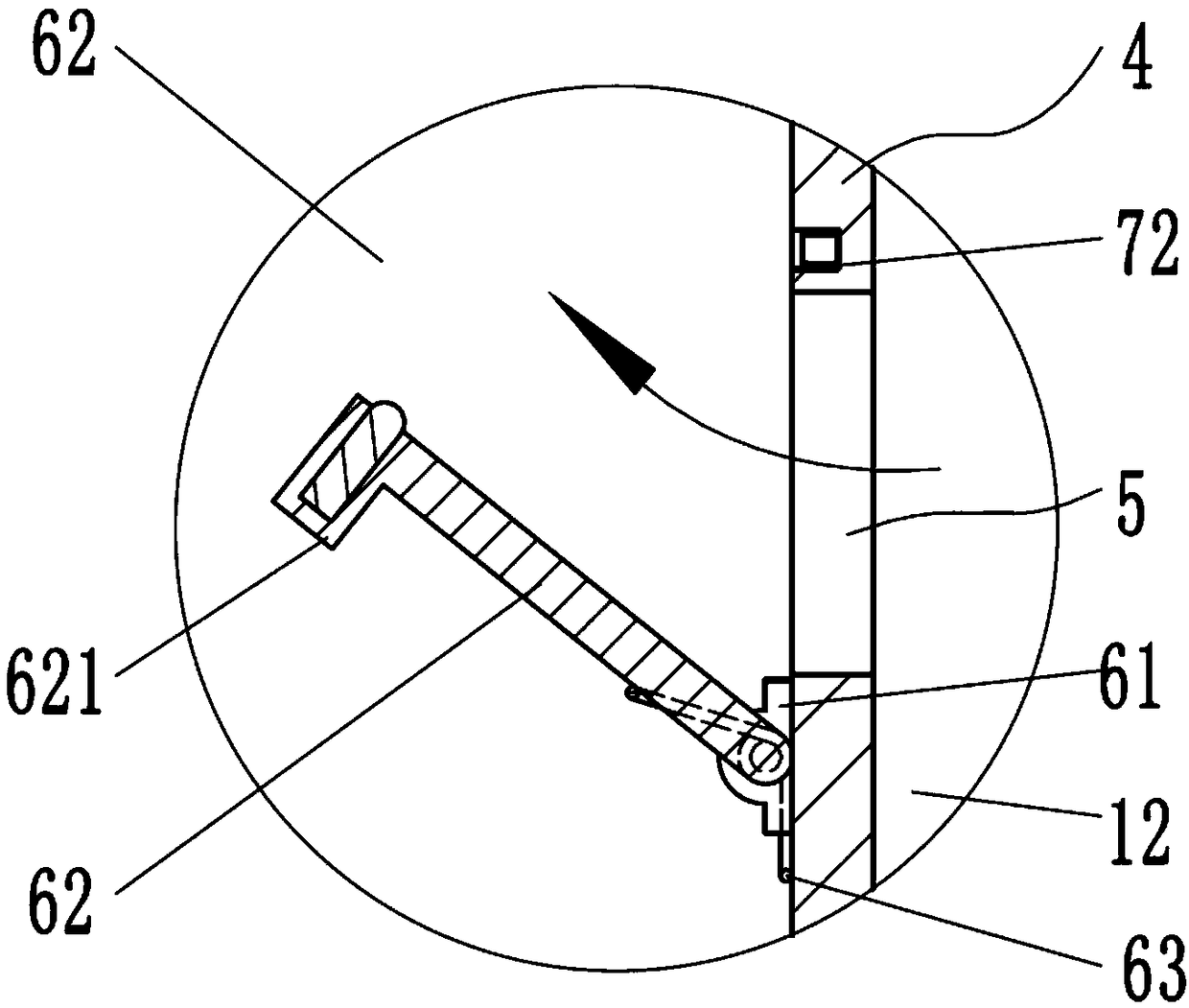

[0028] refer to Figure 1 to Figure 4 ,Such as figure 1 A kind of bean grinding and peeling device shown includes a machine body 10, a grinding wheel set 20 installed in the machine body 10, an air exhaust device 30 is installed above the grinding wheel set 20, and a gap between the air exhaust device 30 and the grinding wheel set 20 An air duct 40 is provided, wherein it also includes a bean curd conveying device, and the bean curd conveying device includes a conveying cylinder 4, and the conveying cylinder 4 is arranged in the skin storage box 1 positioned at the upper end of the air passage 40, and the conveying The cylinder 4 divides the inner chamber of the leather storage box 1 into an outer chamber 11 and an inner chamber 12, and the air duct 40 communicates with the inner chamber 12, and the side wall of the delivery cylinder 4 is provided with There are several one-way ventilation holes 5 to make the outer chamber 11 communicate with the inner chamber 12, and the air...

Embodiment 2

[0035] Such as figure 2As shown, the spiral core 3 is movably arranged in the air duct 40, the spiral core 3 includes a core rod 31 and a spiral blade 32 arranged on the outer periphery of the core rod 31, and one end of the core rod 31 pivots Connected on the bottom of the delivery cylinder 4, since the spiral core 3 is provided in the present invention, when the air exhaust device 30 extracts the air in the outer chamber 11, the spiral blade 32 will be rotated, and the bean curds will rotate along the spiral. When the helical channel formed by the blades 32 rises, it will move upwards rapidly under the promotion of the helical blades 32, which improves the collection efficiency of bean curds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com