A casting and forging integrated device adopting toggle link mold clamping structure

A connecting rod lock and toggle technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as non-self-locking, large mold expansion force, and large mold clamping force , to achieve stable filling, good force and stable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

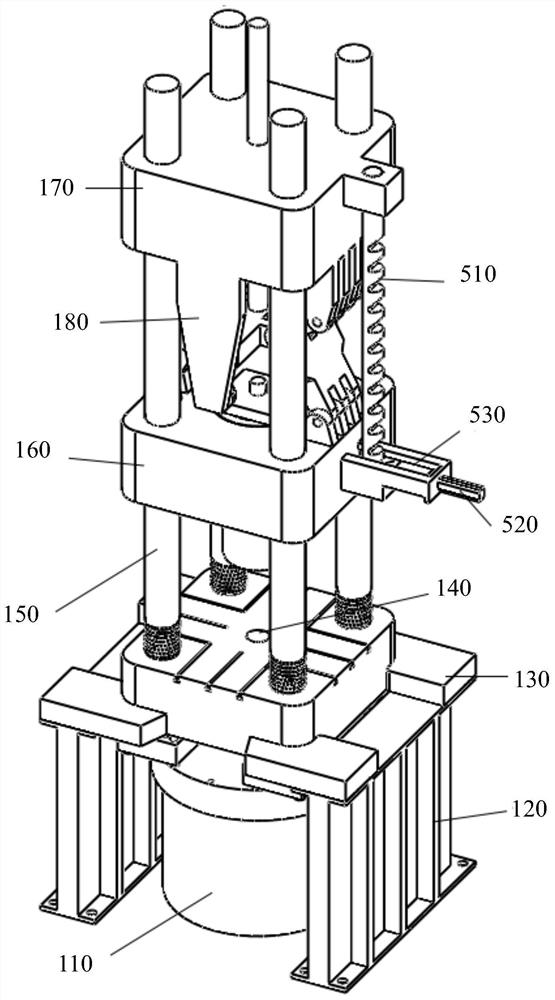

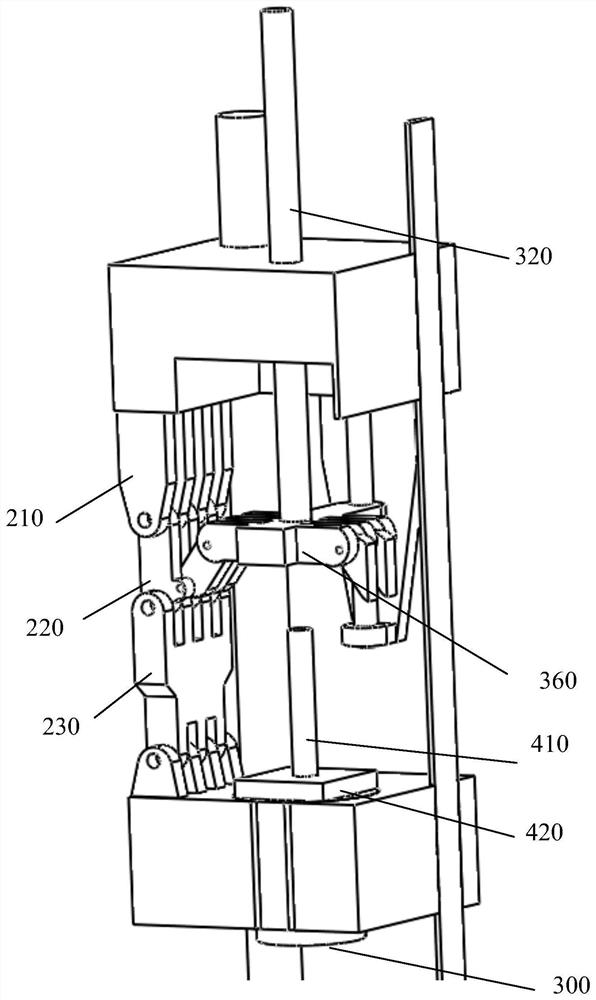

[0054] Such as Figure 1-3 As shown, the integrated casting and forging device adopting the toggle link clamping structure provided by the present invention includes: a casting system 110 , a base 120 , a lower platen 130 , a movable platen 160 , an upper platen 170 and a toggle mold clamping system 200 .

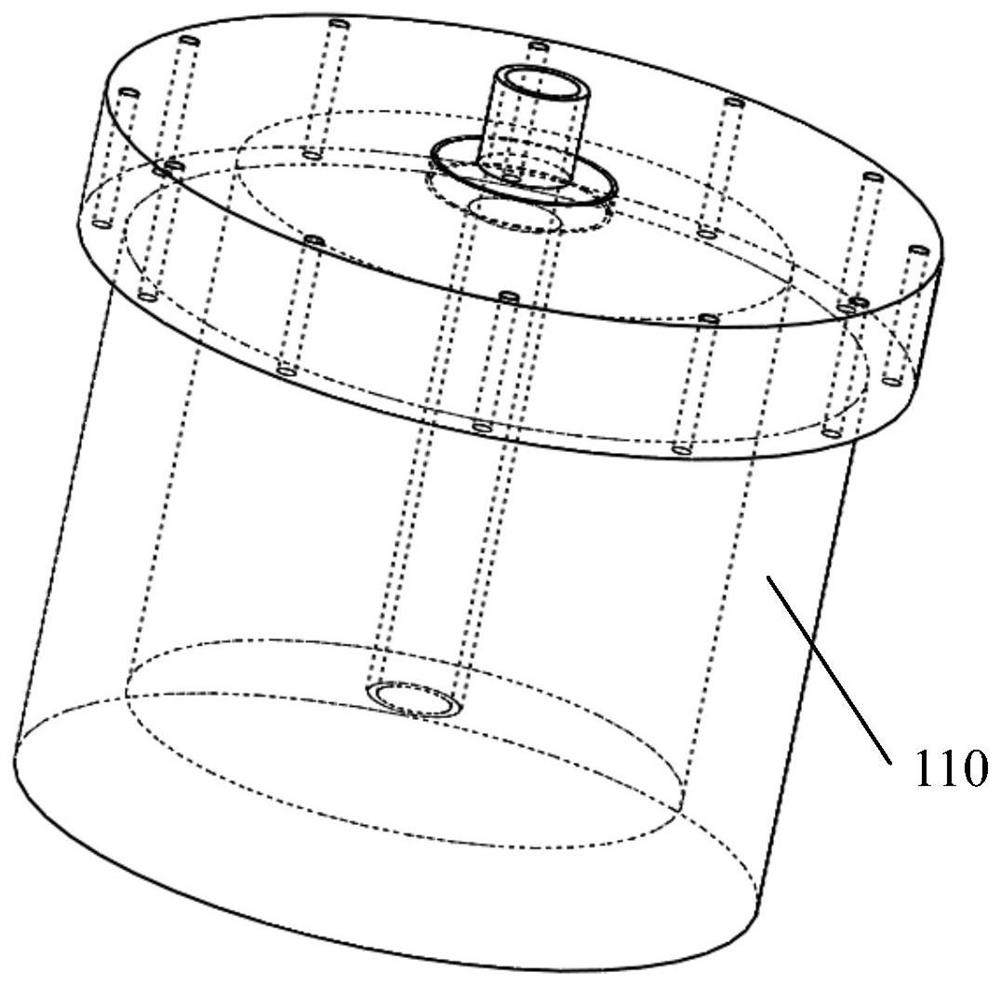

[0055] The casting system 110 is a low-pressure automatic filling system, a low-pressure casting furnace, which is integrated under the integrated casting and forging device. When working, an air or inert gas pressure 0.01-0.05Mpa higher than atmospheric pressure is applied on the surface of the molten metal in the closed furnace body. The molten metal rises through the liquid riser dipped in the solution, and is pressed into the upper mold connected to the furnace through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com