Blister subsequent die cutter cutting forming device

A molding device and mold knife technology, applied in the direction of metal processing, etc., can solve problems such as product quality impact, time delay, and high labor intensity, and achieve the goal of improving personal and equipment safety, reducing strength and personal safety, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

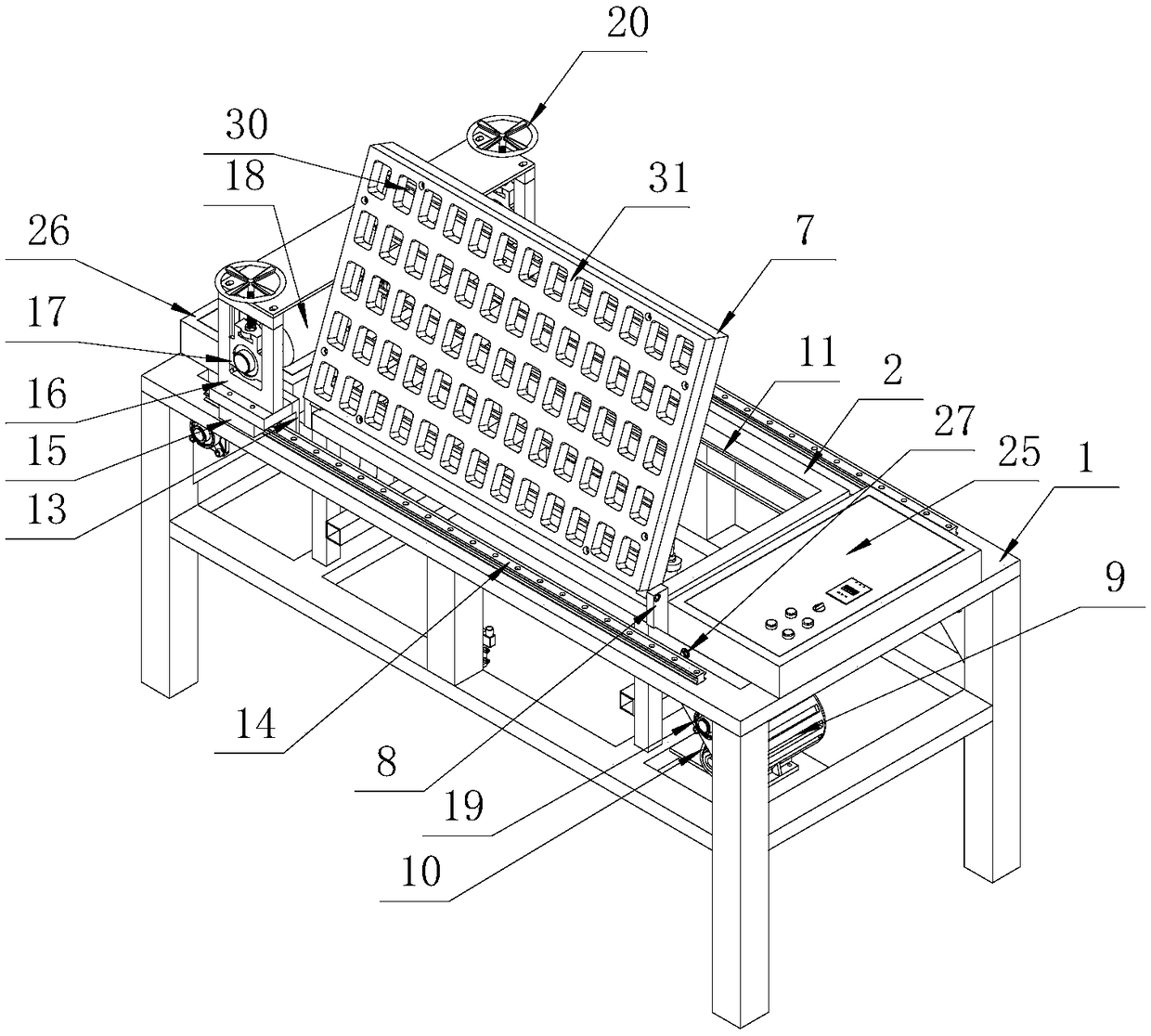

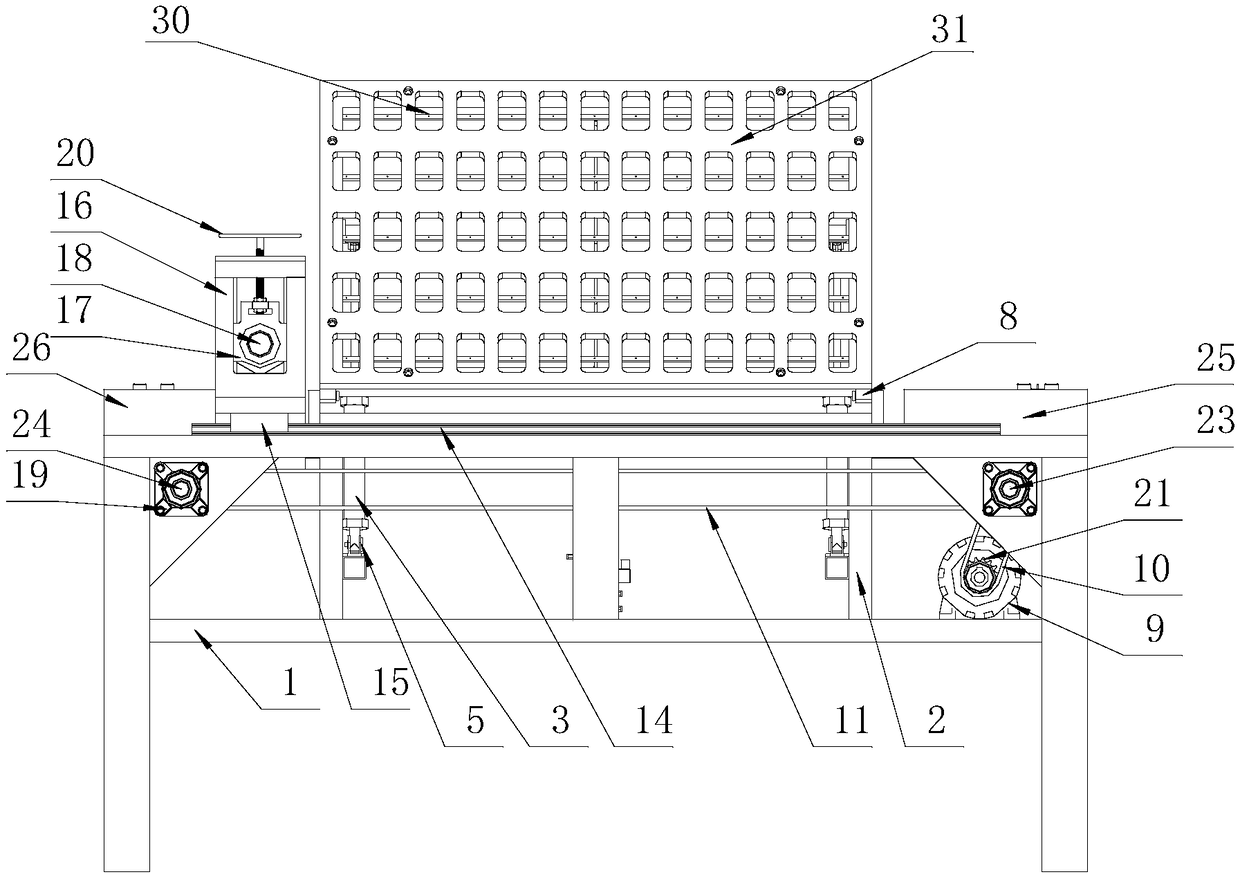

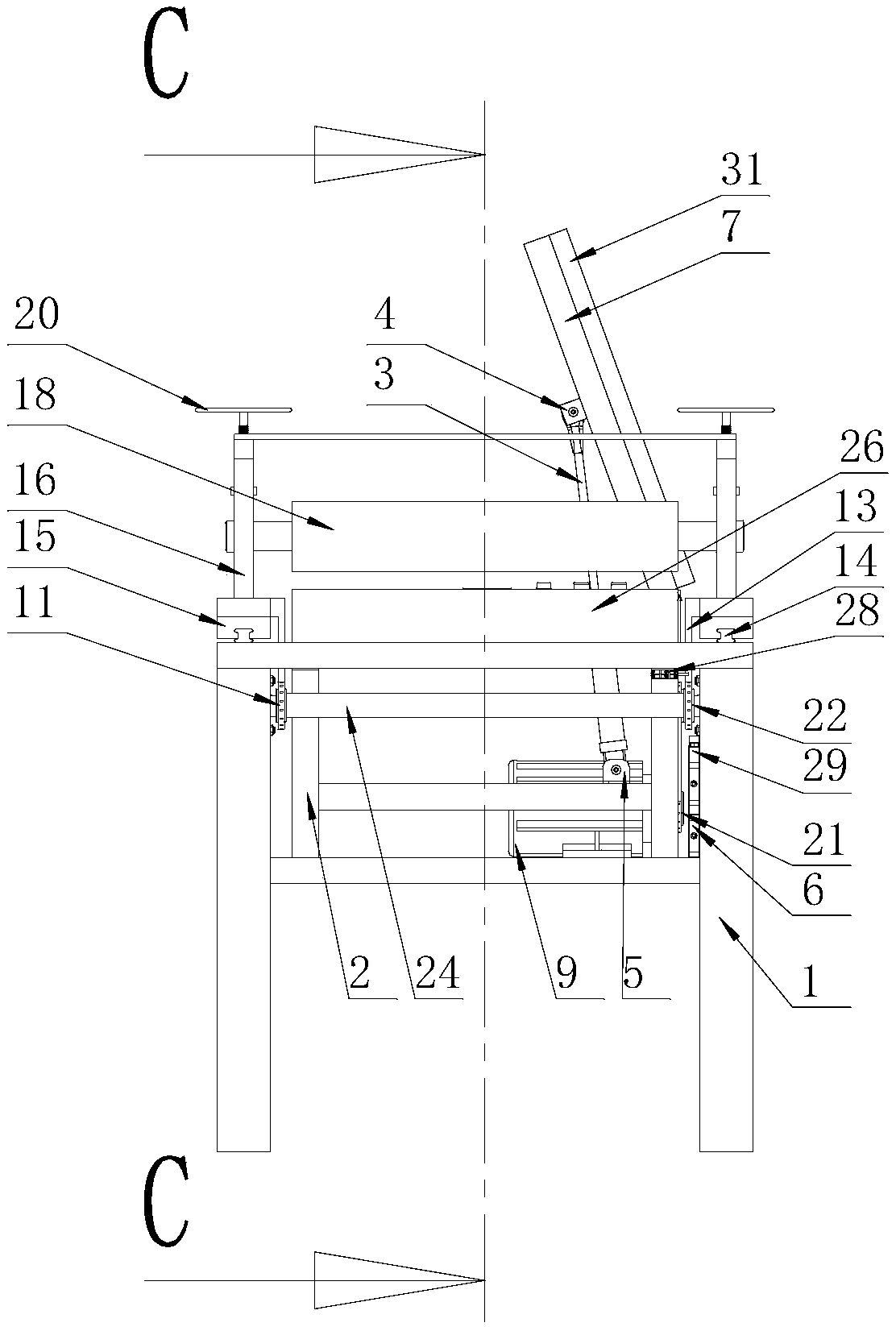

[0047] see Figure 1 to Figure 14 : The embodiment of the present invention provides a kind of mold knife cutting molding device after blistering, comprising outer bracket structure 1, inner bracket structure 2, pressure roller movement mechanism, mold knife turning mechanism, automatic blowing mechanism and electric control mechanism, inner The support structure 2 is inside the outer support structure 1; the outer support structure 1 is a frame welded by metal square pipes and channel steel, and the outer support structure 1 is provided with a pressure roller movement mechanism and an electric control mechanism; The inner support structure 2 is a frame welded by metal square pipes and channel steels. This frame is inside the outer support structure 1. The inner support structure 2 includes a mold knife turning mechanism and an automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com