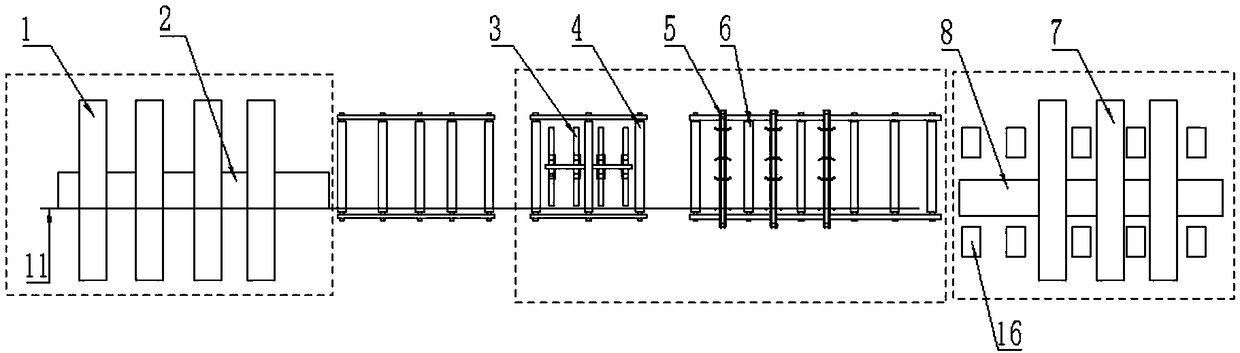

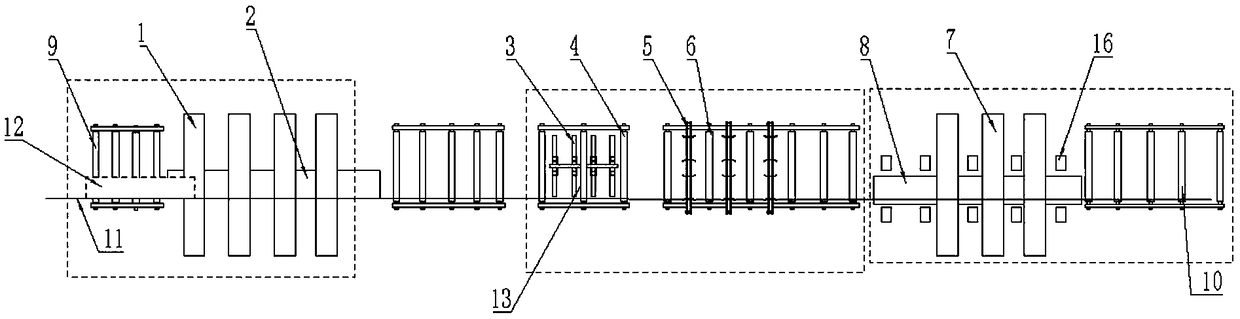

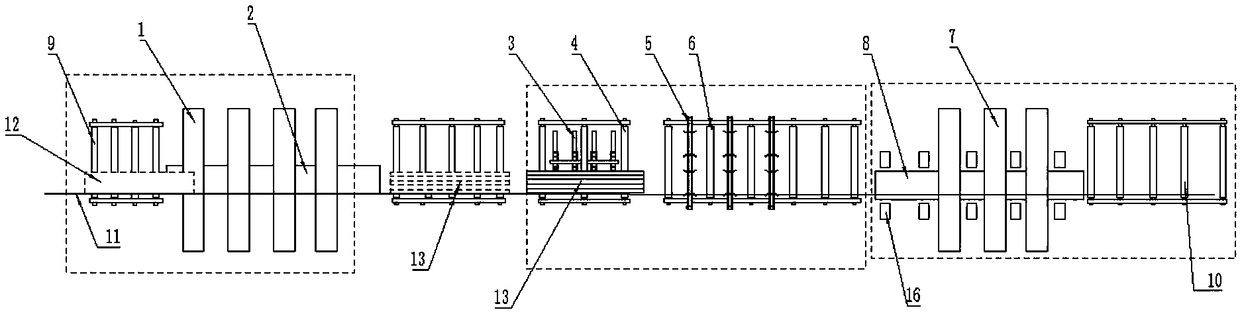

Production line used for board processing

A board processing and production line technology, applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of inflexible use, inapplicability, and inability to realize automation, so as to reduce equipment costs, increase processing efficiency, increase The effect of adjusting the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0128] The difference from Embodiment 1 is that the primary vertical conveying mechanism further includes a first lifting mechanism, and the first lifting mechanism can drive the conveyor rollers of the primary vertical conveying mechanism to move up and down simultaneously.

[0129] The three-stage longitudinal conveying mechanism further includes a third elevating mechanism, and the third elevating mechanism can drive the conveying rollers of the three-stage longitudinal conveying mechanism to move up and down simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com