Hub motor driving system of double-rotor motor integrated drum brake

A dual-rotor motor, drum brake technology, applied in the direction of brakes, brake components, motion deposition, etc., can solve the problems of deteriorating the driving comfort and handling stability of electric vehicles, increasing the unsprung mass and the moment of inertia of the wheel hub, etc. Improve system efficiency and power density, compact structure, improve power density and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

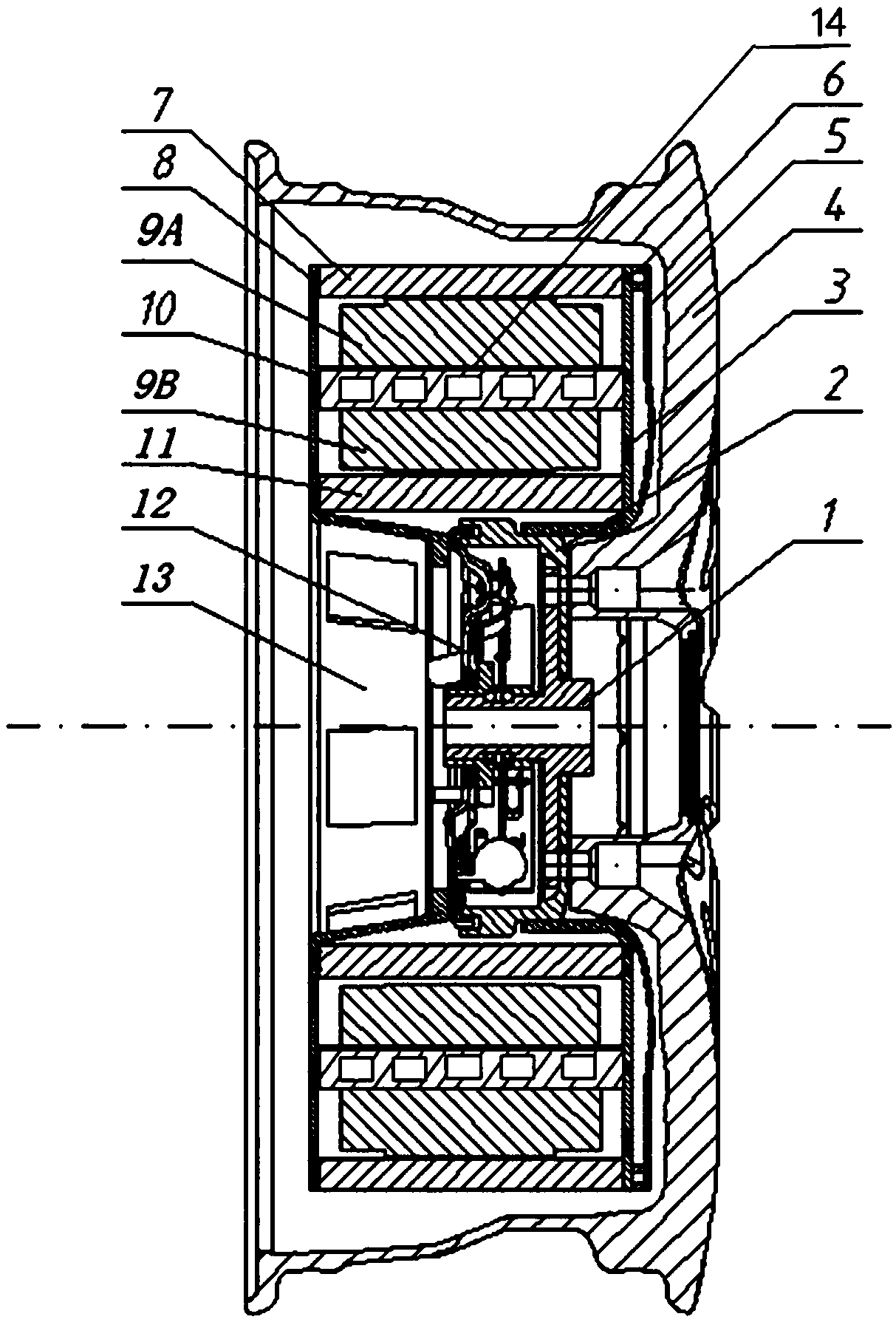

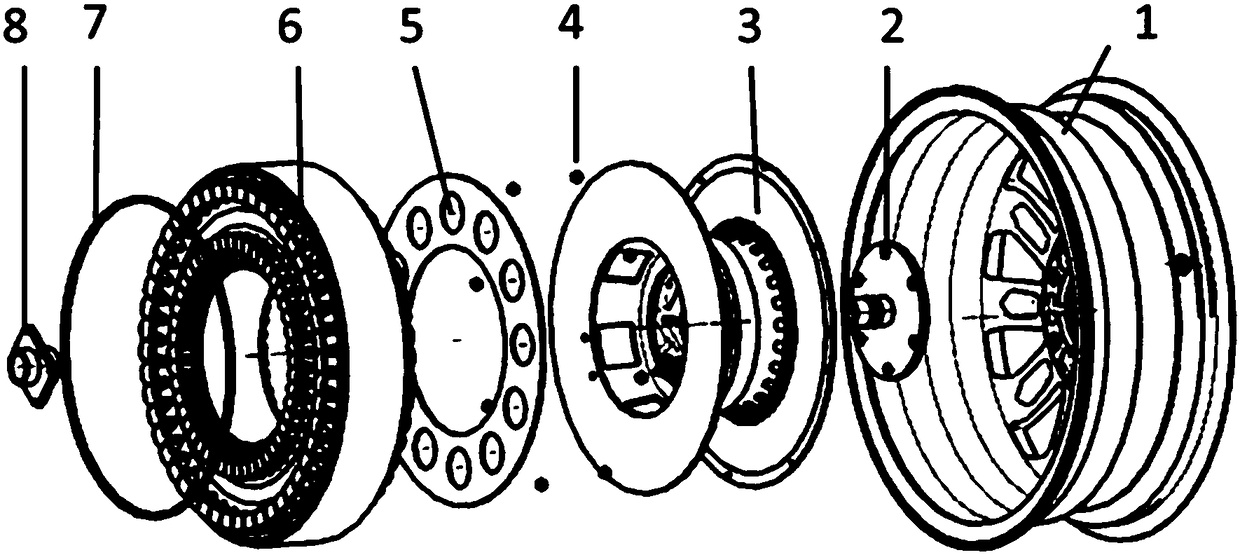

[0023] The hub motor drive system of this dual-rotor motor integrated drum brake is mainly composed of hub bearing 1, brake drum 2, rotor support plate 3, rim 4, heat dissipation plate 5, support sleeve 6, outer rotor 7, sealing ring 8, stator Assembly 9, outer stator winding 9A, inner stator winding 9B, stator support plate (including cooling water channel) 10, inner rotor 11, brake actuator (brake shoe, brake wheel cylinder, etc.) 12, brake base plate 13.

[0024] Such as figure 1 and 2 As shown, the dual-rotor motor and the drum brake are integrated in the rim of the drive wheel. The double-rotor motor is mainly composed of outer rotor 7, outer stator assembly 9, stator support plate (including cooling water channel) 10, inner stator winding 9B, inner rotor 11 and other components. The drum brake is mainly composed of brake base plate 13, brake actuator 12 (brake shoe, brake wheel cylinder, etc.), brake drum 2 and other components. The outer rotor 7 and the inner rotor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com