Overturning machine for lifting roll material

A technology of turning machine and turning frame, which is applied in the direction of lifting device, lifting frame, conveyor, etc., can solve the problems of troublesome feeding process, many parts, complicated structure, etc., and achieve convenient operation, less manual labor and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

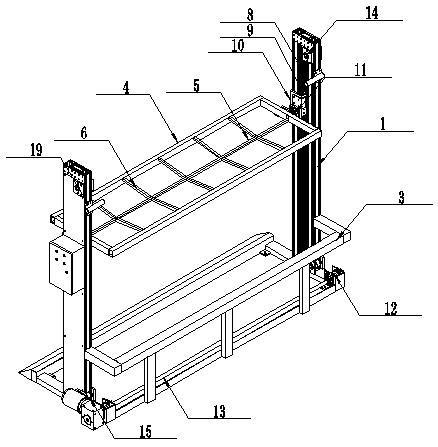

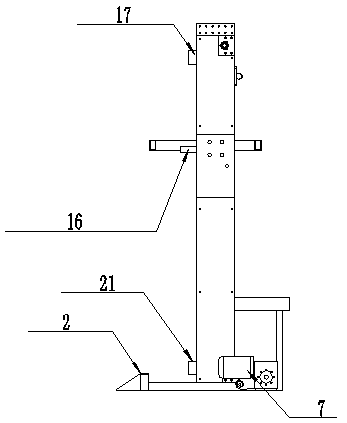

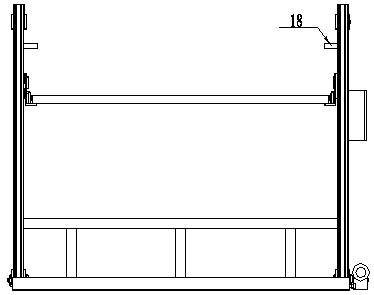

[0029] like Figure 1-Figure 7 A kind of coil lifting and turning machine shown, comprises

[0030] An overturning frame, the overturning frame includes a pair of vertically arranged columns 1 that are relatively distributed, and there is a gap between the two columns 1 for the movement of coiled materials.

[0031] Also be provided with a feed plate 2 on the feeding side of the turning frame, the upper end face of the feed plate 2 is an inclined plane, and the inclination direction of the feed plate 2 is gradually upwardly inclined from the feed plate 2 to the column 1 direction. By setting the feeding plate 2 with an inclined surface, it is convenient for the coil material to be directly rolled into the lifting and turning plate without manual handling, thereby reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com