Working method of utilizing intelligent device to clamp various building bricks

A technology of intelligent devices and working methods, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low transportation efficiency, complicated management, insecurity, etc., and achieve the effect of good effect, space saving and efficient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

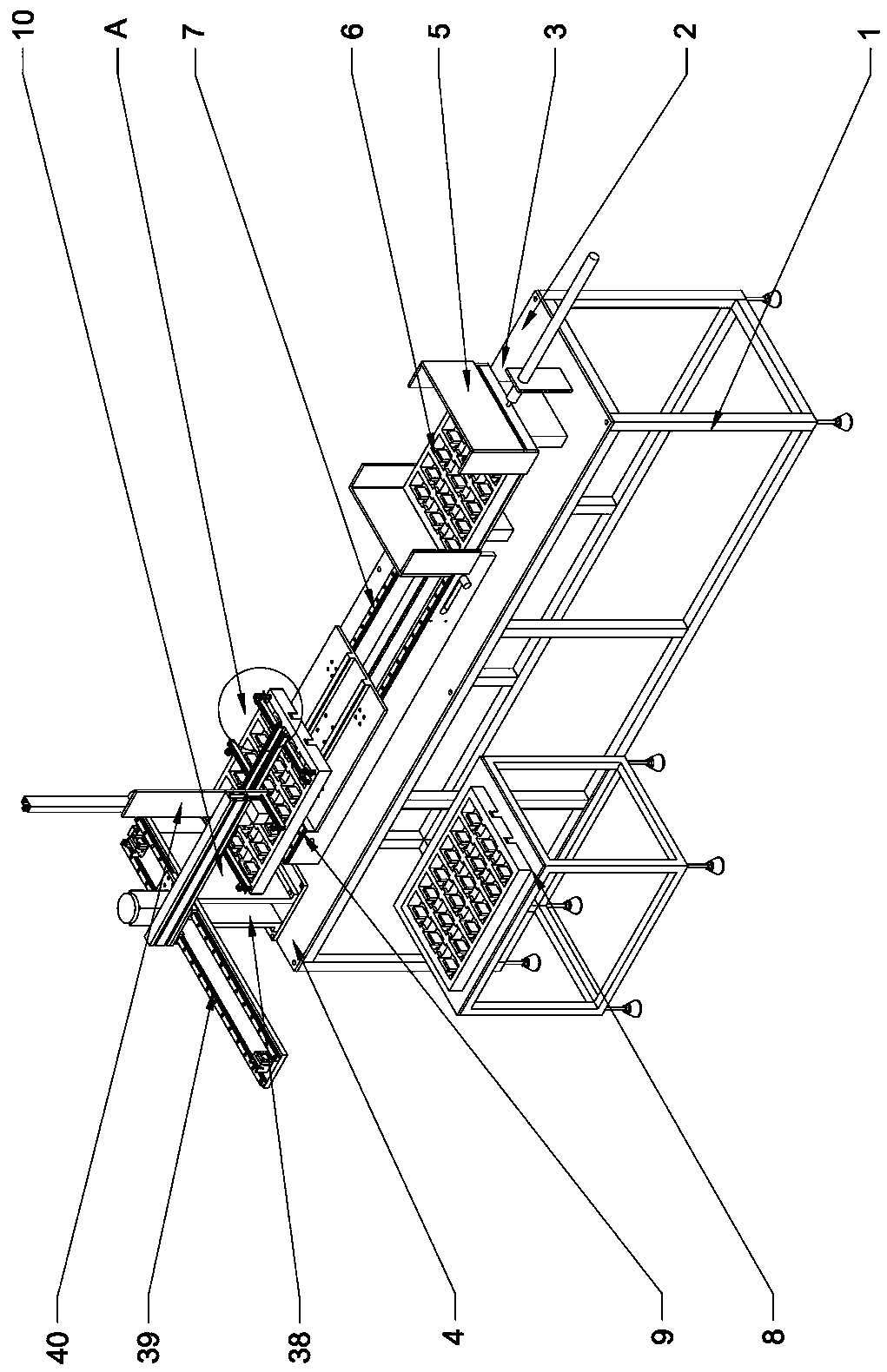

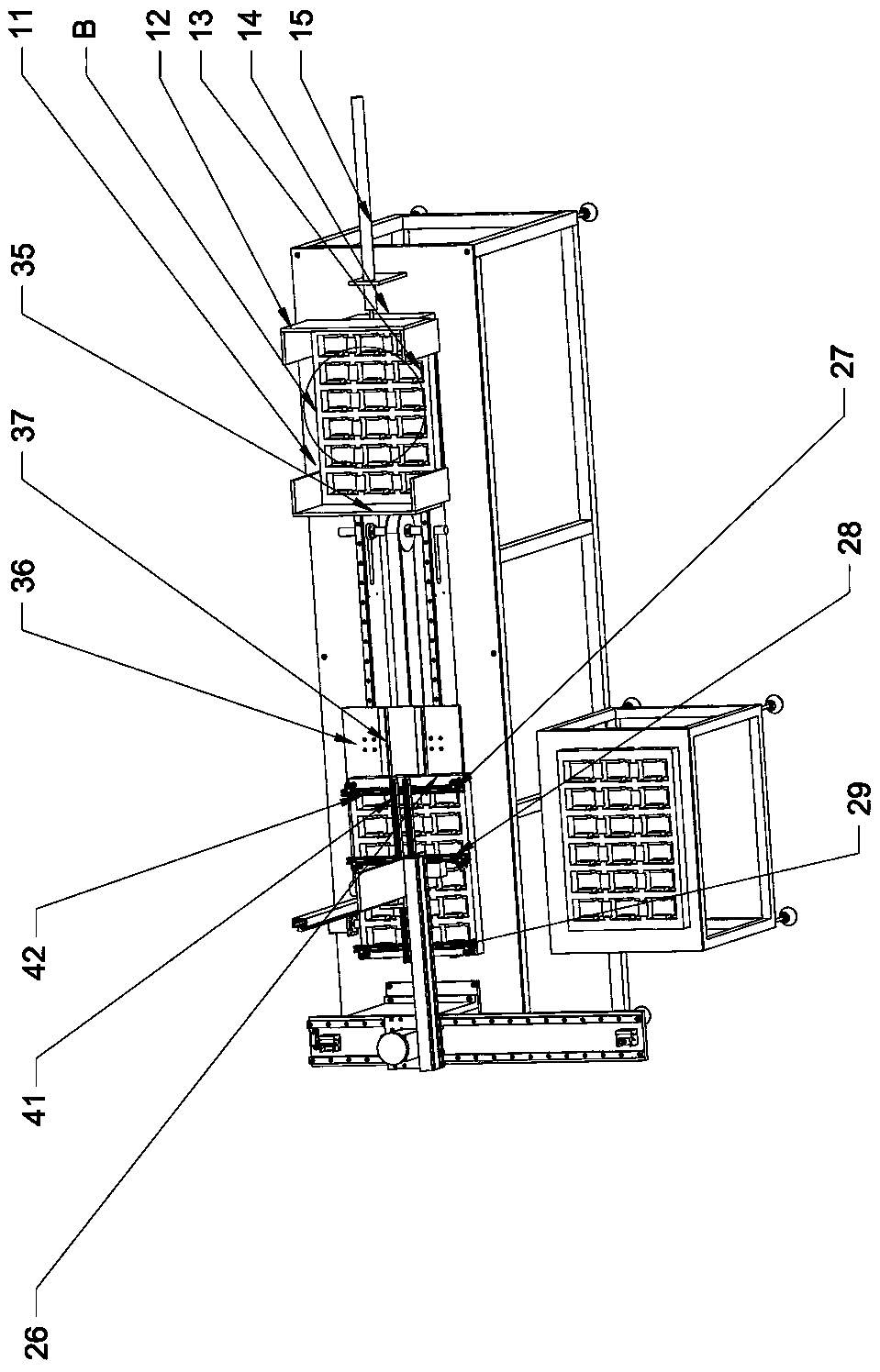

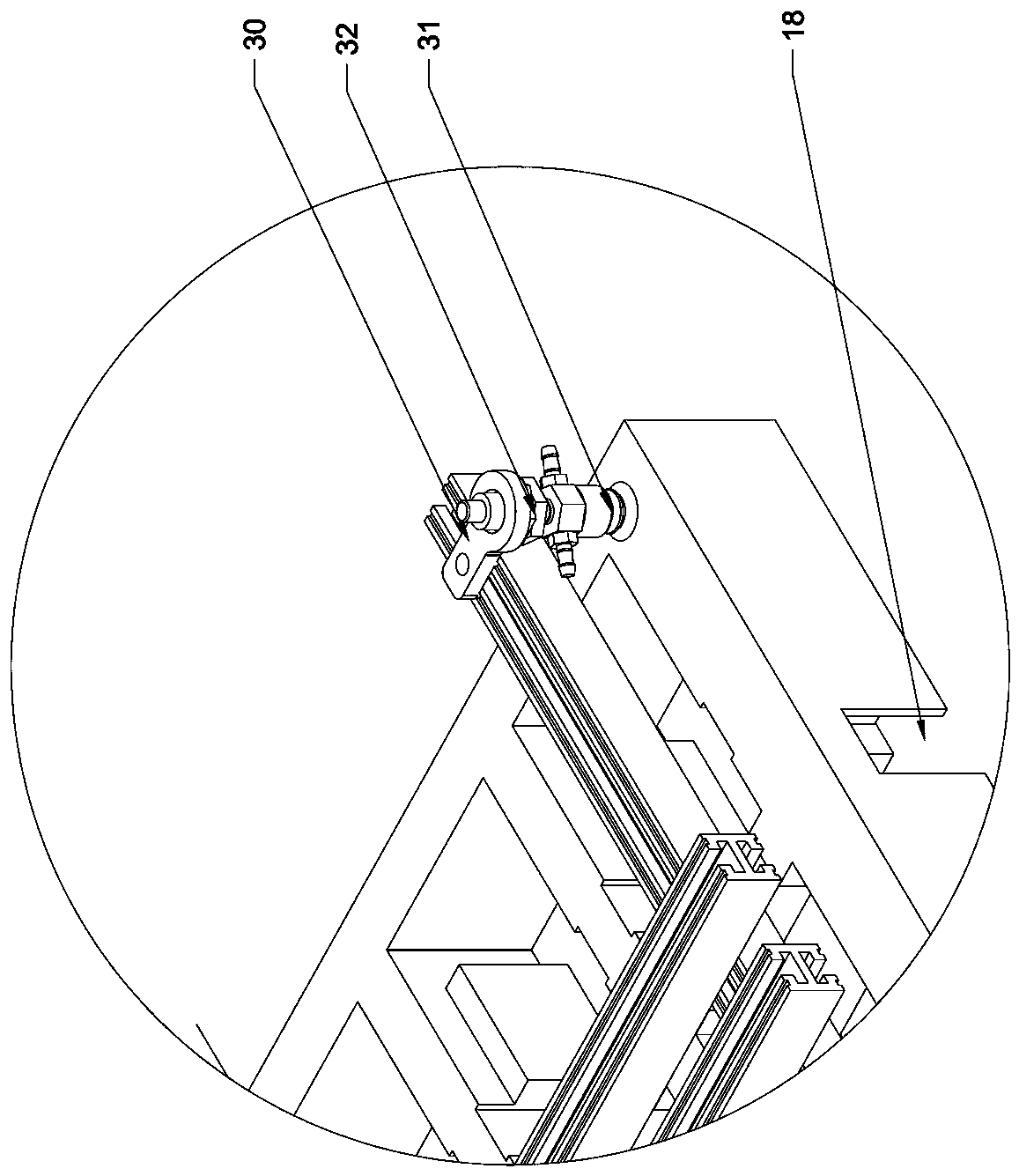

[0028] Such as Figure 1-7 As shown, the purpose of the present invention is achieved in this way: a kind of working method that utilizes intelligent device to clamp various types of building blocks, comprises main frame 1, is arranged on the working platform 2 on main frame 1; The entrance 3 is provided with a smart tray placement part 5, and several groups of smart trays 6 are arranged at the smart tray placement part 5; a transport assembly 7 is arranged between the entrance 3 and the exit 4 of the working platform 2, and The head end cooperates with the intelligent tray placement part 5, and the end 9 of the transport assembly 7 is equipped with a transfer manipulator 10; the transfer manipulator 10 is provided with a smart tray placement part 5; The working method of the block is,

[0029] Including step 1, driving the manipulator to the vicinity of the intelligent tray placement part 5, running the intermediate conveyor belt, and moving the bracket 36 to a position clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com