Preparation method of a sawtooth-like nickel-cobalt-iron-like Prussian blue sintered oxide nanomaterial

A technology of Prussian blue-like and nanomaterials is applied in the field of preparation of zigzag-like Prussian blue-like sintered oxide nanomaterials, which can solve problems such as bisphenol A pollution, and achieve the effects of increasing surface area, simple process conditions, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a sawtooth-like nickel-cobalt-iron-like Prussian blue sintered oxide nanomaterial, comprising the following steps:

[0037] (1) Preparation of NiCoFe-PBA precursor:

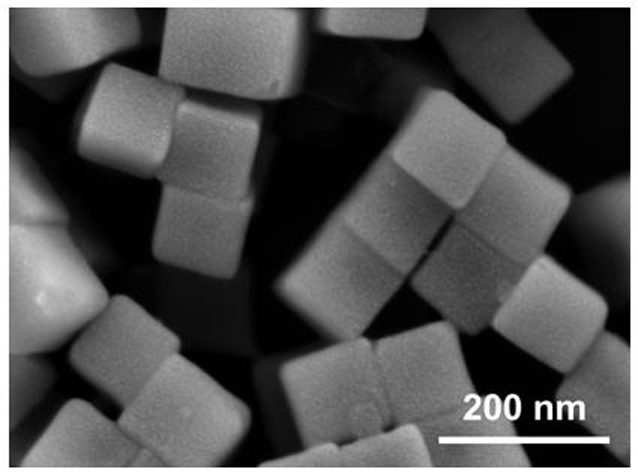

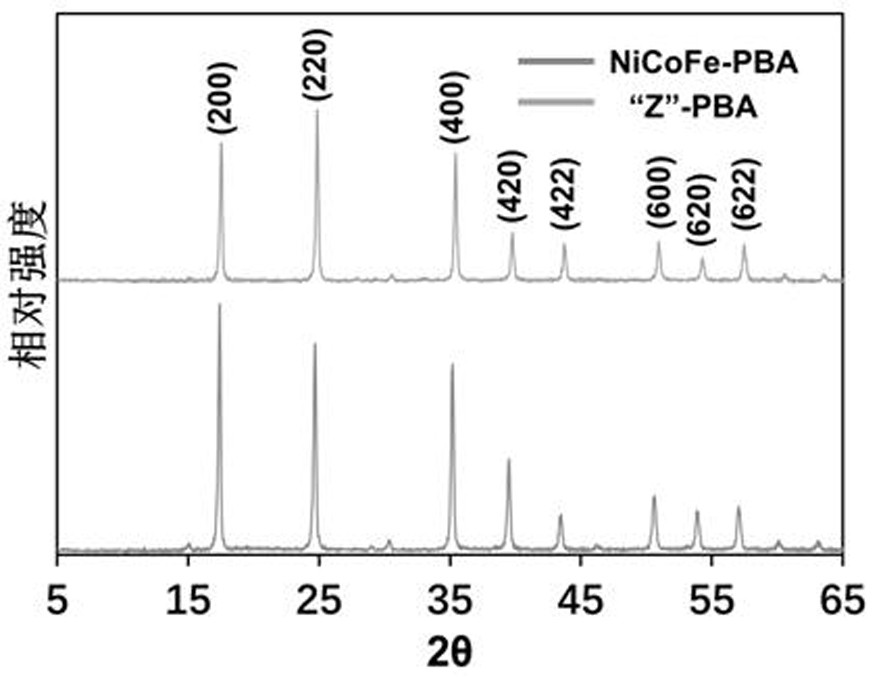

[0038] Using potassium ferricyanide, potassium cobaltcyanide, trisodium citrate trihydrate and nickel nitrate hexahydrate as raw materials, NiCoFe-PBA was prepared by hydrothermal synthesis;

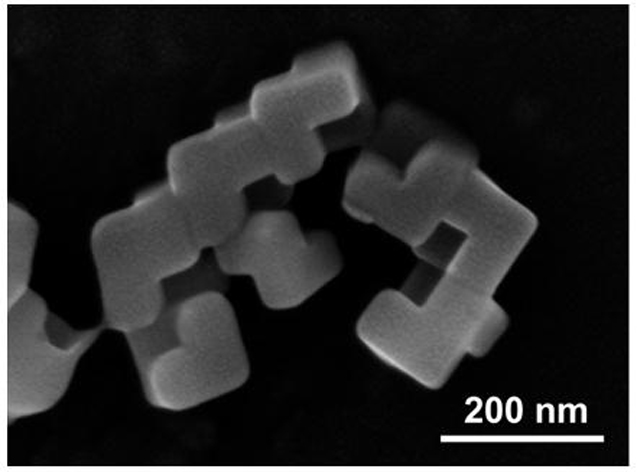

[0039] (2) Preparation of "Z"-PBA nanomaterials:

[0040] Uniformly disperse the NiCoFe-PBA obtained in (1) into 10 ml of ethanol and stir until completely dispersed to obtain a mixed solution; then slowly pour the ammonia solution into the mixed solution and stir for 1 h; then centrifuge the reaction solution , and washed; put the washed samples in an oven at 70 °C for 12 h for drying to obtain “Z”-PBA nanomaterials.

[0041] (3) Preparation of "Z"-Ox nanomaterials:

[0042] The "Z"-PBA nanomaterial sample obtained in step (2) was put into a muffle furnace, kept at 350 °C for 1.5 h, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com