Special device for mold preheating

The technology of a special device and mold is applied in the field of special device for mold preheating, which can solve the problems of complex structure, high cost, large volume, etc., and achieve the effect of reducing heat loss too quickly and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

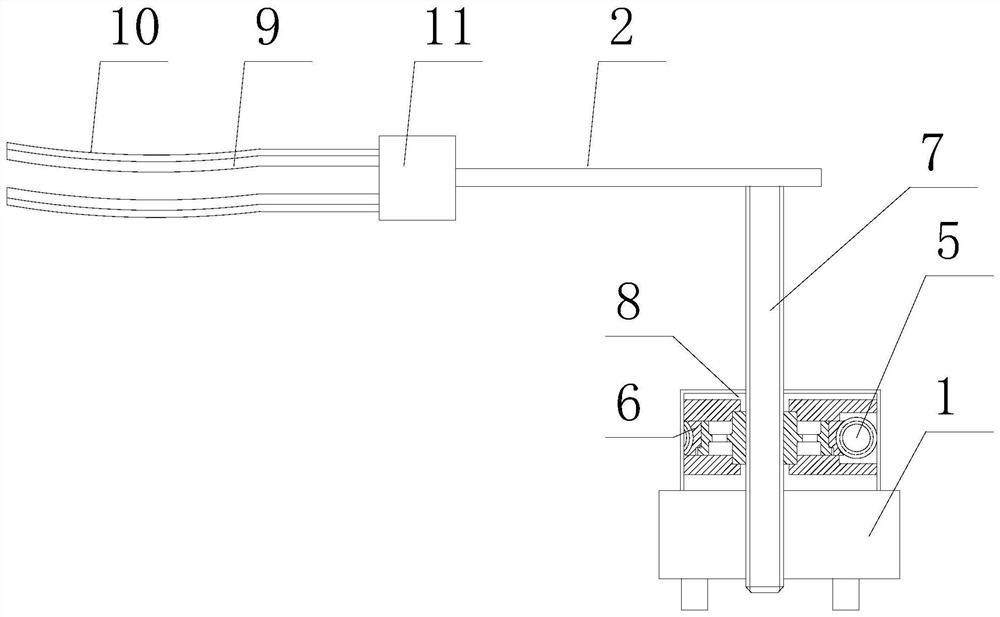

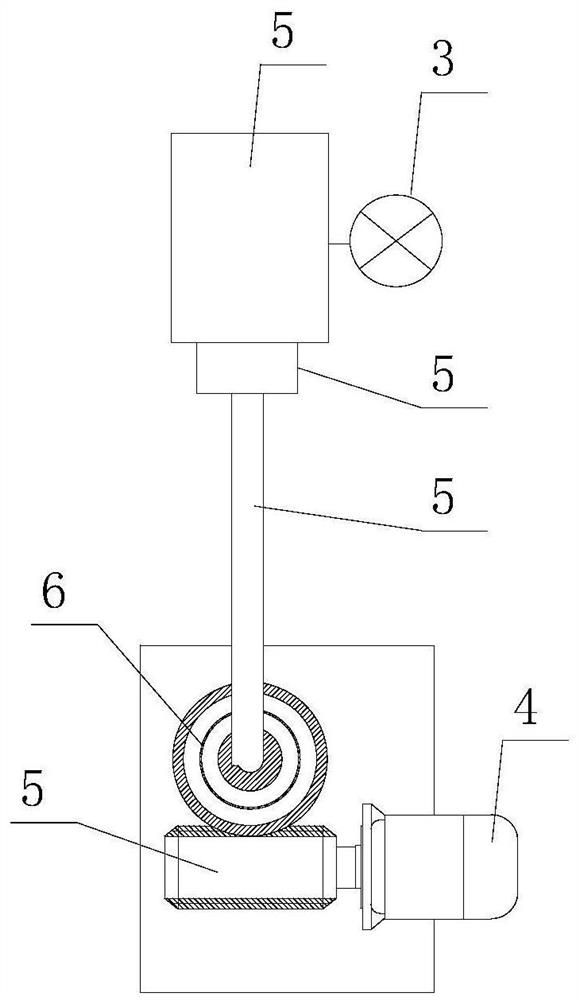

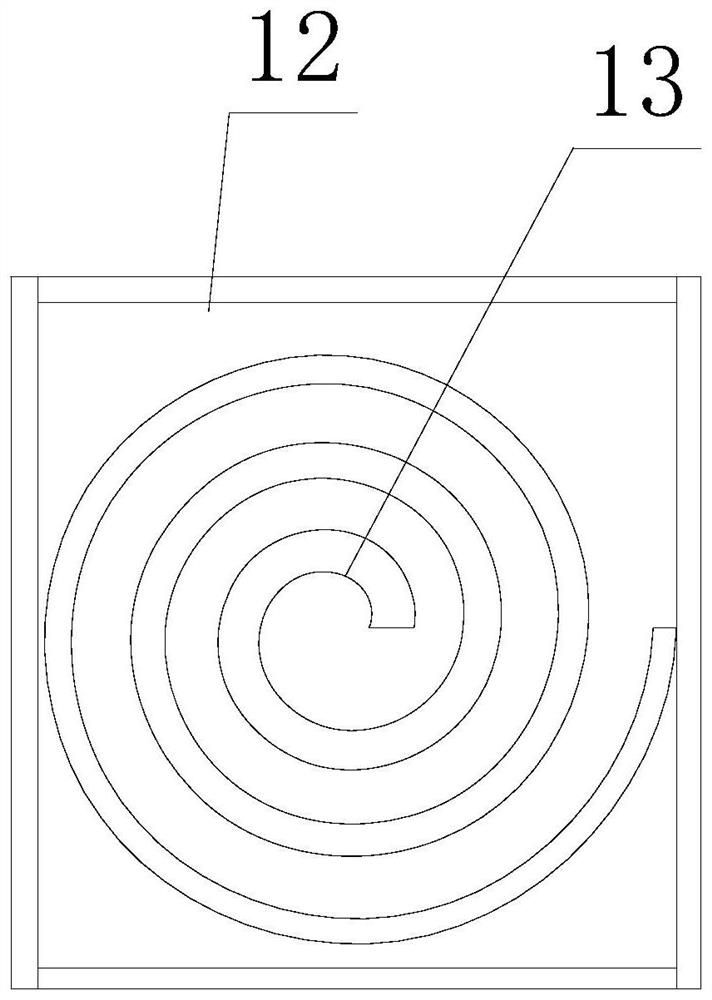

[0027] Embodiment 1, as attached figure 1 , figure 2 , image 3 and Figure 4 Shown:

[0028] The special device for mold preheating includes a base 1, the base 1 is vertically provided with a lifting mechanism, the upper end of the lifting mechanism is movably connected to a moving rod 2, a heating jacket is slidably connected to the moving rod 2, and a power supply 3 is connected to the heating jacket; The lifting mechanism includes a motor 4, the output shaft of the motor 4 is connected with a worm 5, the worm 5 is engaged with a worm wheel 6, and the center hole of the worm wheel 6 is engaged with a vertical screw 7, and the upper end of the screw 7 is fixedly connected to one end of the moving rod 2, The worm wheel 6 and the worm 5 joint are provided with a baffle 8 to prevent the axial movement of the worm wheel 6; the heating jacket includes two layers of arc-shaped heating nets 9 arranged up and down, and the heating net 9 is fixed with an insulating layer 10, and ...

Embodiment 2

[0035] Embodiment 2, as attached Figure 5 Shown:

[0036] The difference from Embodiment 1 is that the heating grid 9 is formed by criss-crossing linear heating wires, which facilitates the installation and manufacture of heating wires, and facilitates the replacement and maintenance of a single heating wire. The insulation layer 10 is a high temperature resistant fiber layer structure, simple in structure, and easy to install and replace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com