A structure for reducing heat loss in high temperature pipelines

A heat loss and pipeline technology, applied in pipeline protection, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of reducing the design temperature of pipeline materials, increasing costs, and function failure, so as to reduce heat transfer loss and reduce processing and manufacturing costs , to prevent the effect of personnel burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention will be described below in conjunction with the accompanying drawings.

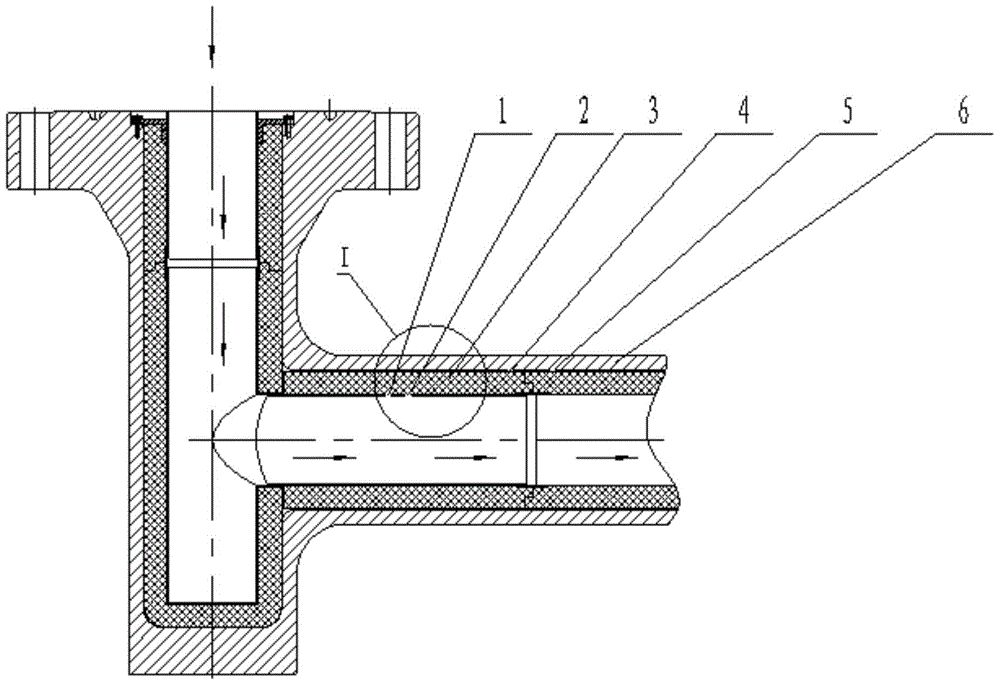

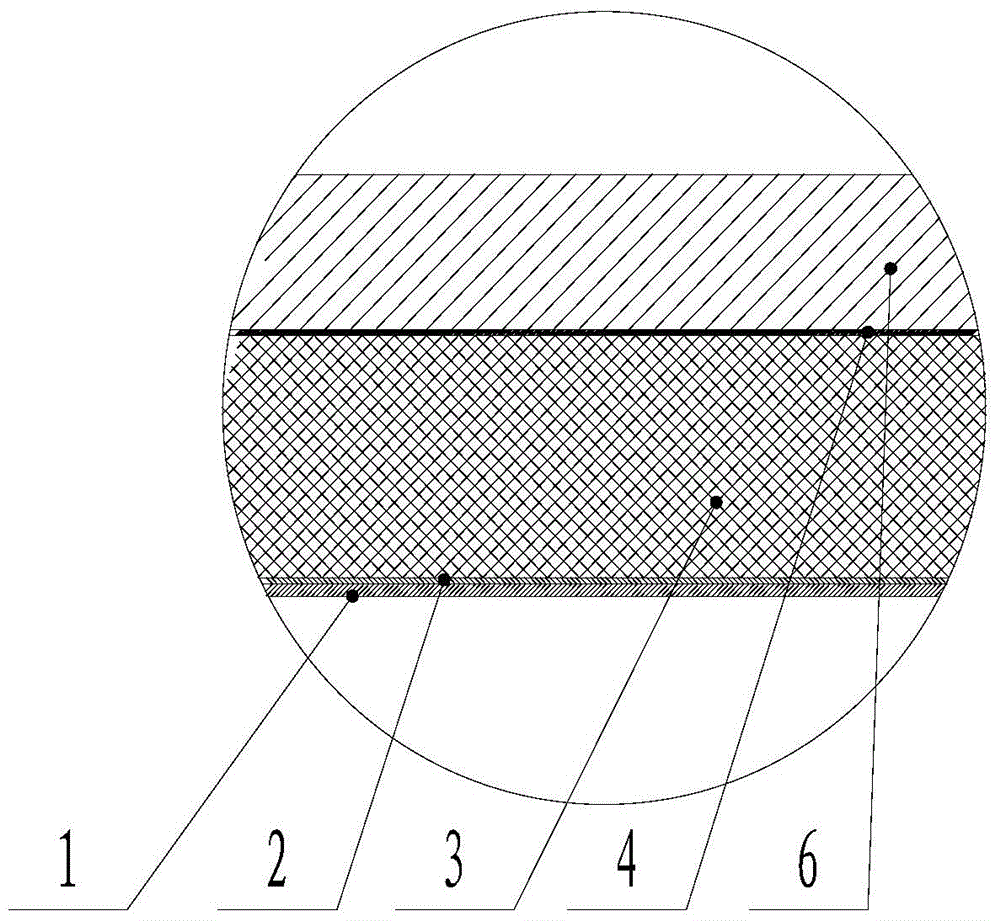

[0020] Such as figure 1 , figure 2 As shown, a structure for reducing the heat loss of high-temperature pipelines includes: an inner lining cylinder 1, a metal silk screen 2, a heat insulation block 3, a metal cylinder 4, a metal wire 5 and a high-temperature pipeline outer casing 6; figure 1 The direction of the middle arrow is the airflow direction.

[0021] The metal silk screen 2 is tightly wrapped on the outer surface of the inner lining tube 1, and the joints of the metal silk screen 2 are crimped to prevent the metal silk screen 2 from slipping off. The metal tube 4 is set outside the inner lining tube 1, and the metal The heat insulation block 3 is filled between the cylinder 4 and the metal silk screen 2, the metal wire 5 is bundled on the outer surface of the metal cylinder 4, and the outer shell 6 of the high-temperature pipeline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com