A heating process method for changing the back-up roll soft belt

A technology of heating process and support roll, which is applied in the field of heat treatment, can solve the problems of excessive soft belt range and unqualified, etc., and achieve the effects of saving manpower, improving quality and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

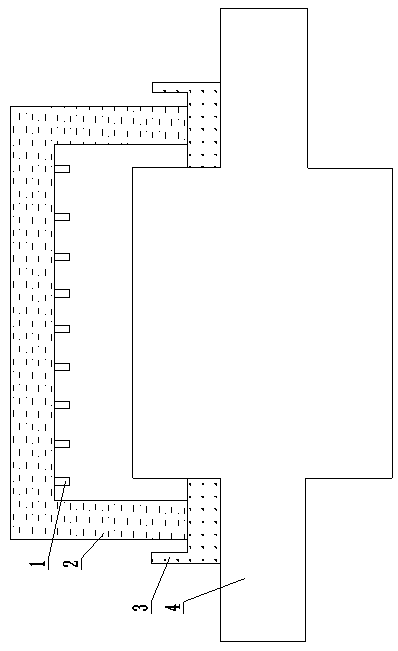

[0014] A heating process method for changing the back-up roll soft belt, the structure of the differential temperature furnace heating device is as follows figure 1 As shown, four rows of several tangential burners 1 are arranged in the furnace shell 2, and a fiber sleeve 3 is arranged between the supporting roller 4 and the furnace shell;

[0015] Concrete steps of the present invention:

[0016] Step 1: Fill the back-up roll in the differential temperature furnace, and install an armored couple at a distance of 80mm from the end face of the roll body at both ends of the back-up roll to monitor the temperature of the piece, and control the temperature of +0°C and -1°C according to the process couple temperature requirements. And a special heat shield is installed to protect the edge during stress relief and tempering;

[0017] Step 2: The end surface of the fiber sleeve 3 extends into the inner surface of the end wall of the furnace shell side by more than 50 mm to reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com