Ignition device for micro turbojet engine and gas turbine combustor

A turbojet engine and gas turbine technology, applied in the direction of gas turbine devices, jet propulsion devices, machines/engines, etc., can solve the problems of immature aerodynamic resonance technology, ignition system cost and increase in volume and weight, and achieve faster flame diffusion speed, The effect of simple and reliable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

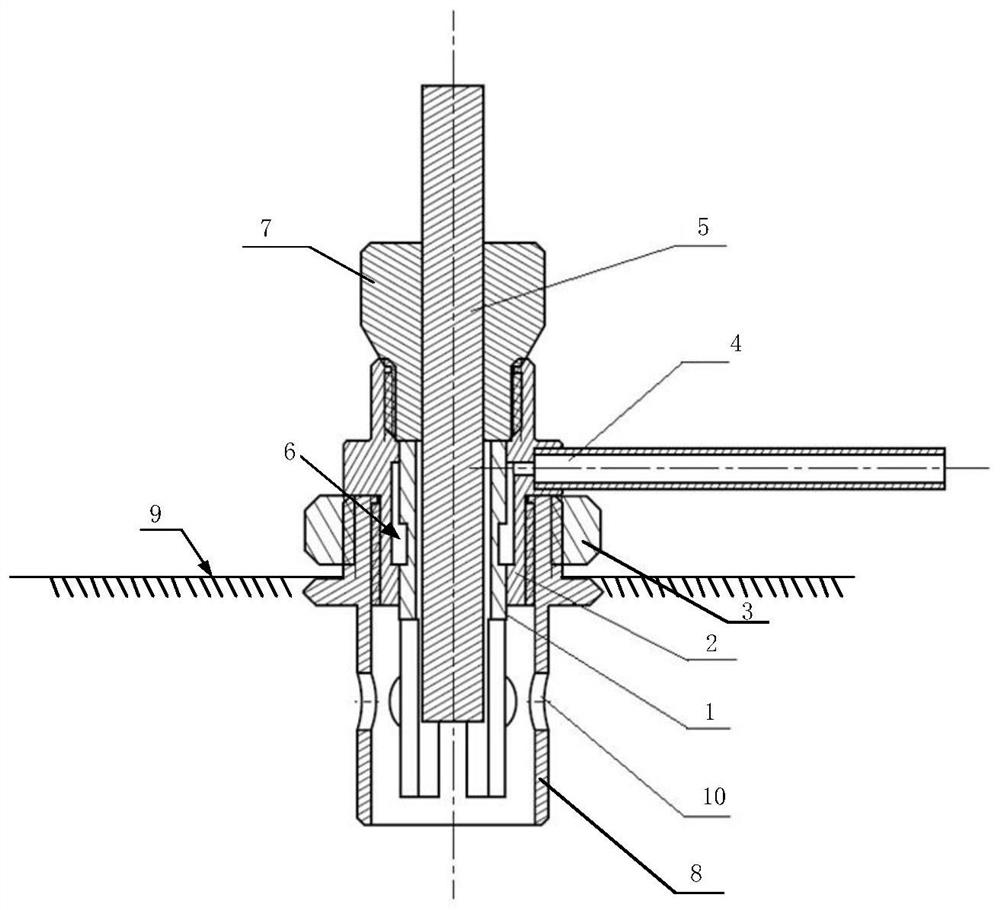

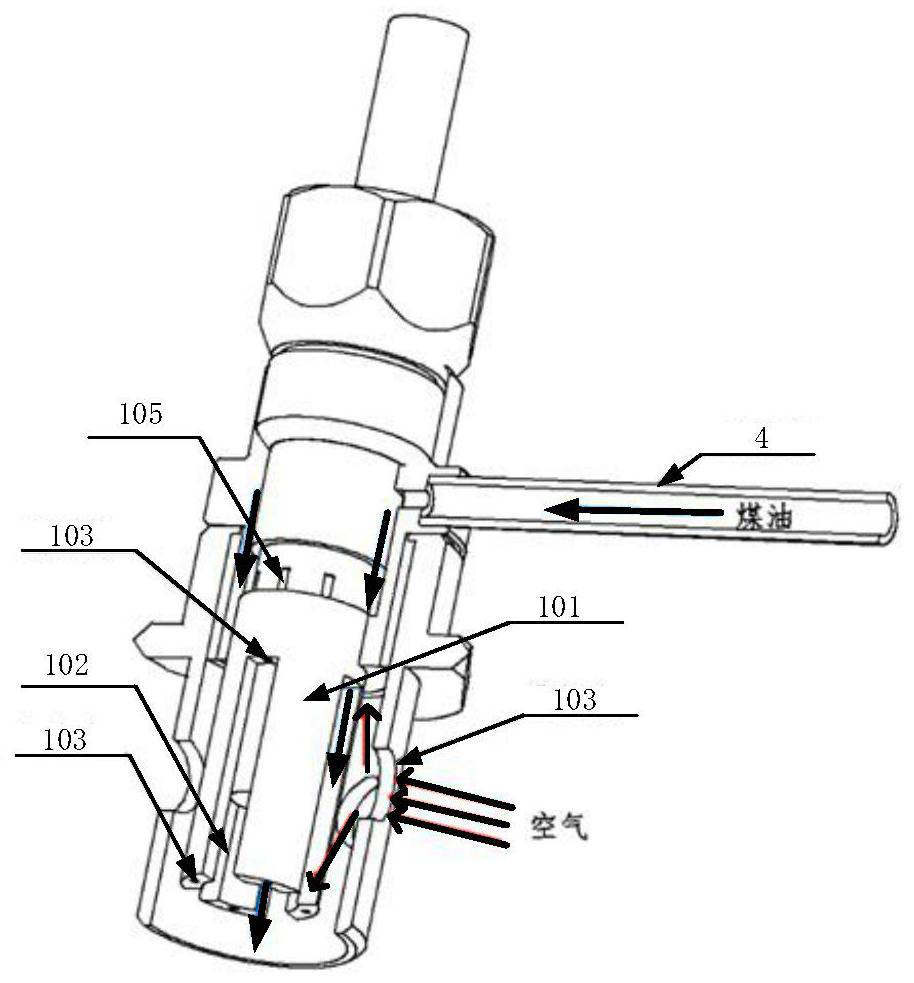

[0034] The ignition device for the miniature turbojet engine and gas turbine combustor of the present invention comprises a kerosene nozzle 1, a kerosene cavity seat 2, a fastening nut 3, an oil inlet pipe 4 and a heating core 5, such as figure 1 shown.

[0035] The kerosene nozzle 1, the kerosene cavity seat 2, the oil inlet pipe 4 and the heating core 5 form an oil circuit assembly. Wherein, the heating core 5, the kerosene nozzle 1 and the kerosene cavity seat 2 are coaxially nested from inside to outside. The upper and lower parts of the kerosene chamber seat 2 are designed with contact shoulders, which are in contact with the top of the kerosene nozzle 1 and the outer wall of the middle part, and are welded and fixed in the circumferential direction to form an integrated weldment, so that the kerosene chamber seat 2 and the kerosene nozzle 1 form a Cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com