Detection device on turbocharger actuator assembly line

A technology of a turbocharger and a detection device, which is applied in the field of actuators, can solve the problems of large interference factors, large labor force, general applicability, etc., and achieves the effect of good applicability and convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

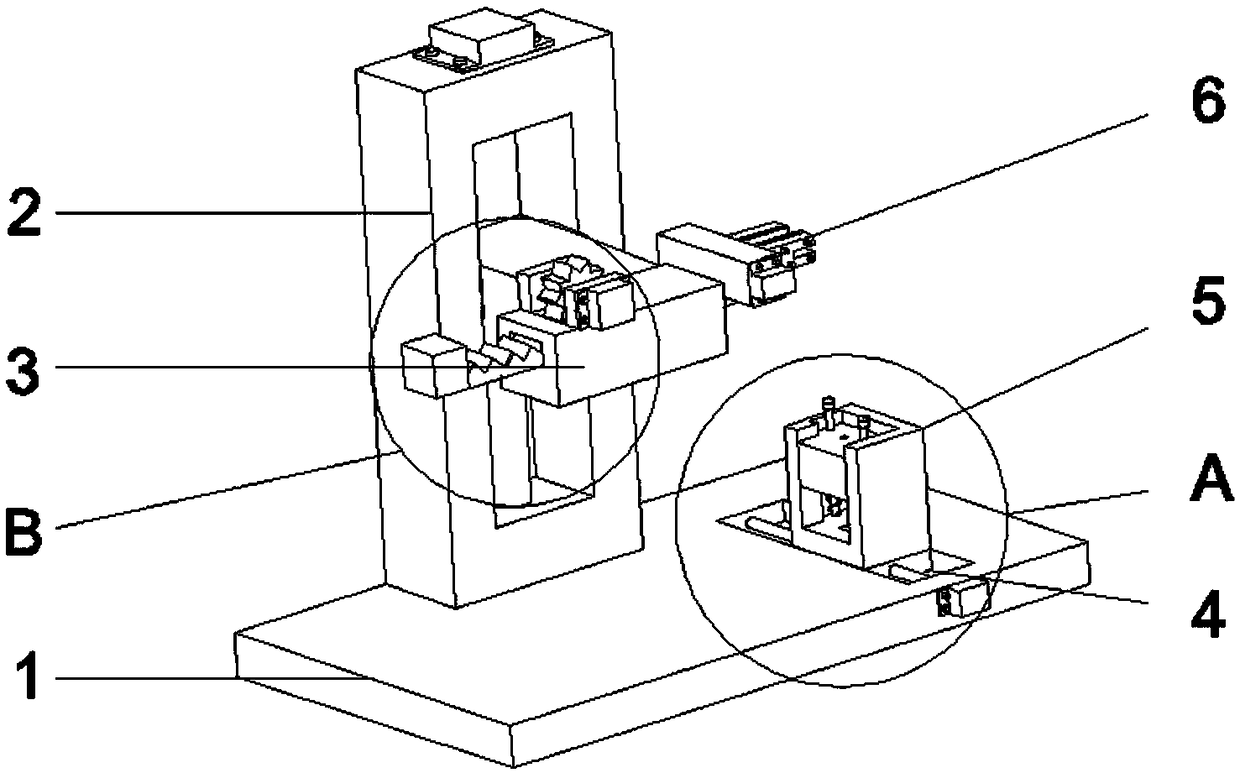

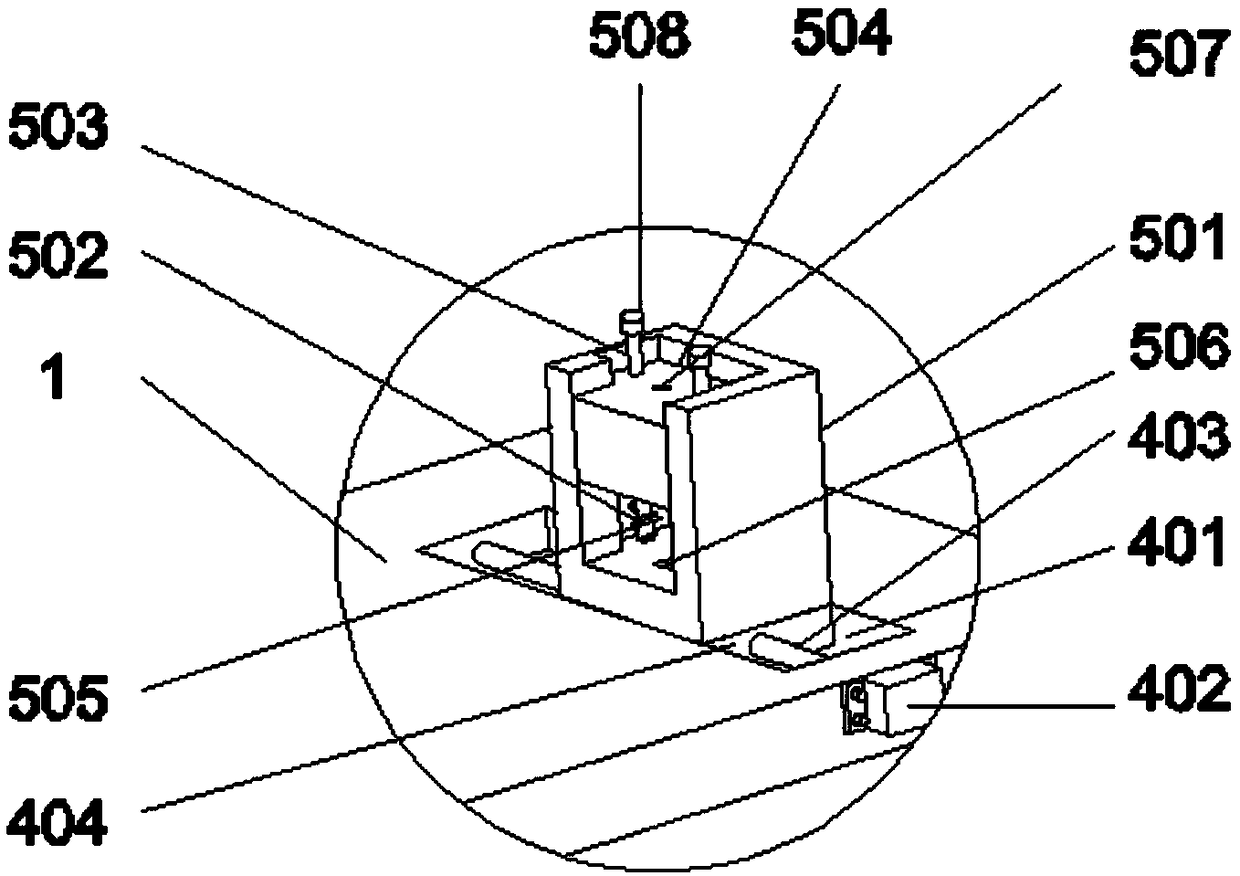

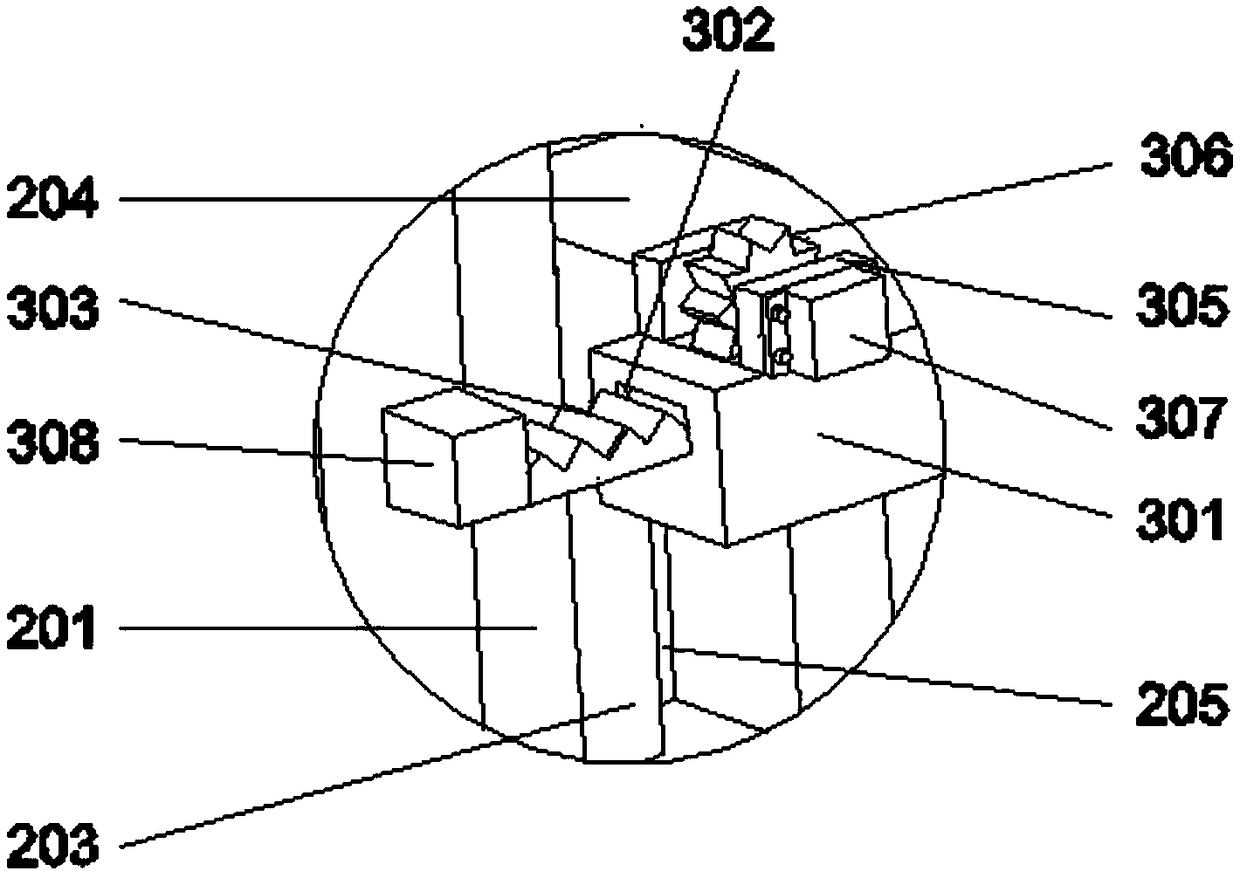

[0024] Such as Figure 1 to Figure 7As shown, a detection device on a turbocharger actuator assembly line includes a base 1, and the base 1 is provided with a lifting mechanism 2, and the lifting end of the lifting mechanism 2 is connected with a lateral sliding mechanism 3. The clamping mechanism 6 includes a clamping bracket 601, a clamping servo motor 602, a clamping threaded rod 603, a first clamping block 604, a second clamping block 605, and a clamping chute 606, and the clamping bracket 601 is connected to the lateral slide The sliding end of the shift mechanism 3, the clamping chute 606 is set on the clamping bracket 601 and is perpendicular to the transverse mechanism 3. The clamping threaded rod 603 is rotatably connected in the clamping chute 606, and the clamping servo The motor 602 is arranged on the clamping bracket 601, and the first clamping block 604 and the second clamping block 605 are arranged symmetrically on the clamping threaded rod 603 and are slidably ...

Embodiment 2

[0027] Such as Figure 1 to Figure 7 As shown, a detection device on a turbocharger actuator assembly line includes a base 1, and the base 1 is provided with a lifting mechanism 2, and the lifting end of the lifting mechanism 2 is connected with a lateral sliding mechanism 3. The clamping mechanism 6 includes a clamping bracket 601, a clamping servo motor 602, a clamping threaded rod 603, a first clamping block 604, a second clamping block 605, and a clamping chute 606, and the clamping bracket 601 is connected to the lateral slide The sliding end of the shift mechanism 3, the clamping chute 606 is set on the clamping bracket 601 and is perpendicular to the transverse mechanism 3. The clamping threaded rod 603 is rotatably connected in the clamping chute 606, and the clamping servo The motor 602 is arranged on the clamping bracket 601, and the first clamping block 604 and the second clamping block 605 are arranged symmetrically on the clamping threaded rod 603 and are slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com