High heat dissipation transformer

A high heat dissipation, transformer technology, applied in transformer/inductor casing, transformer/inductor cooling, transformer/inductor components, etc., can solve the problems of large amount of transformer heat, large vibration amplitude, transformer body pollution, etc., to achieve The structure is scientific and reasonable, the use is safe and convenient, and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

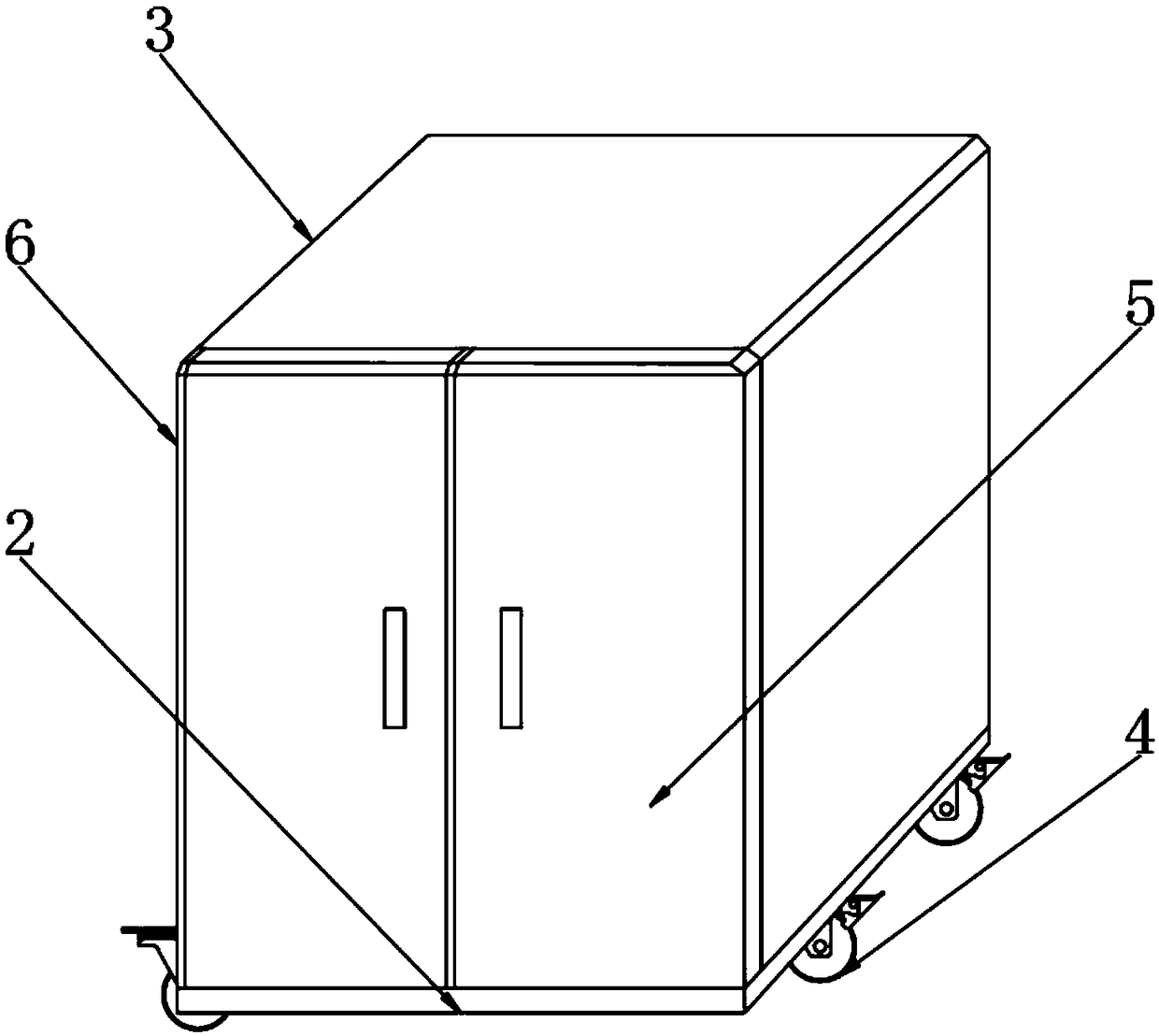

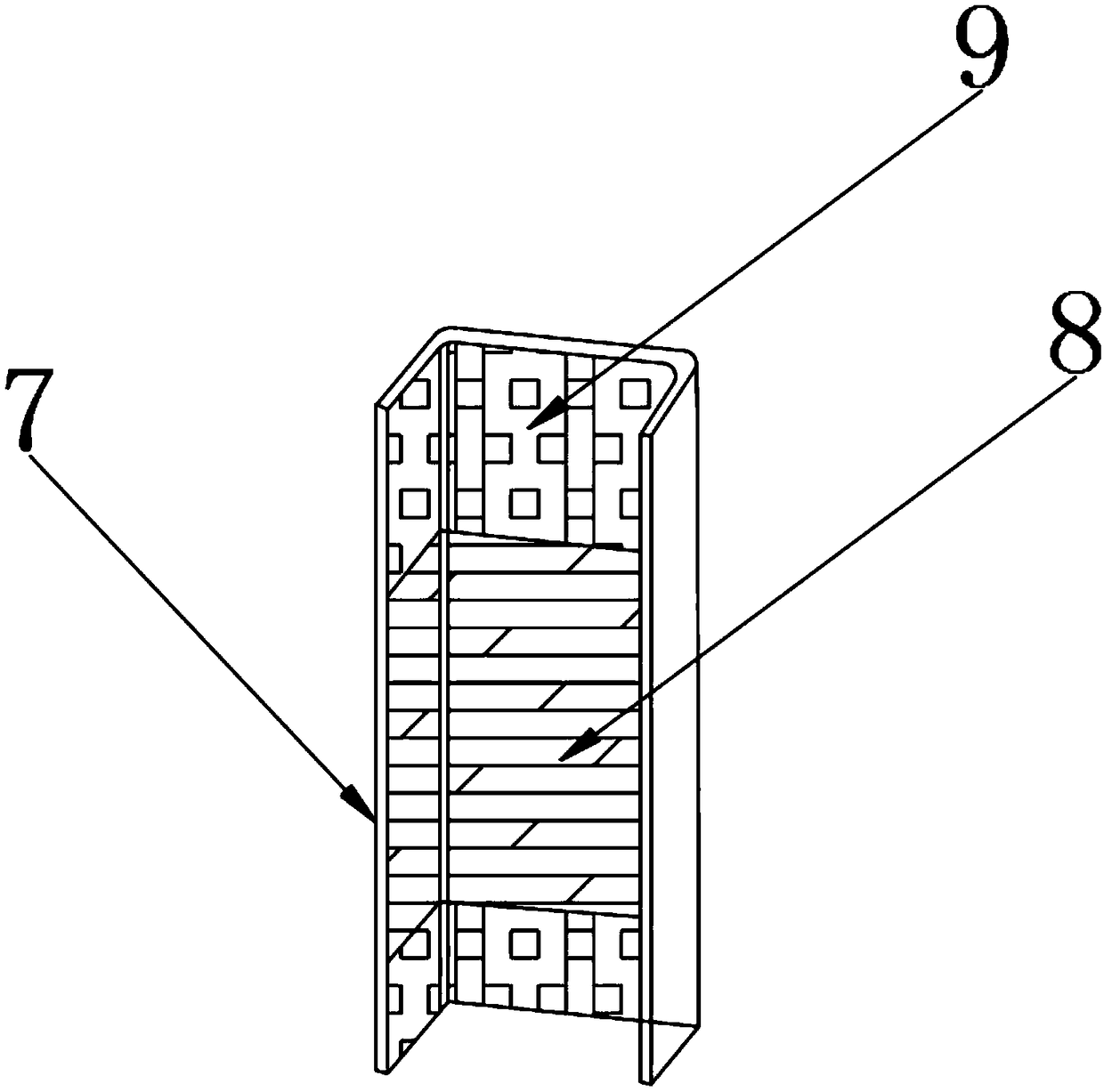

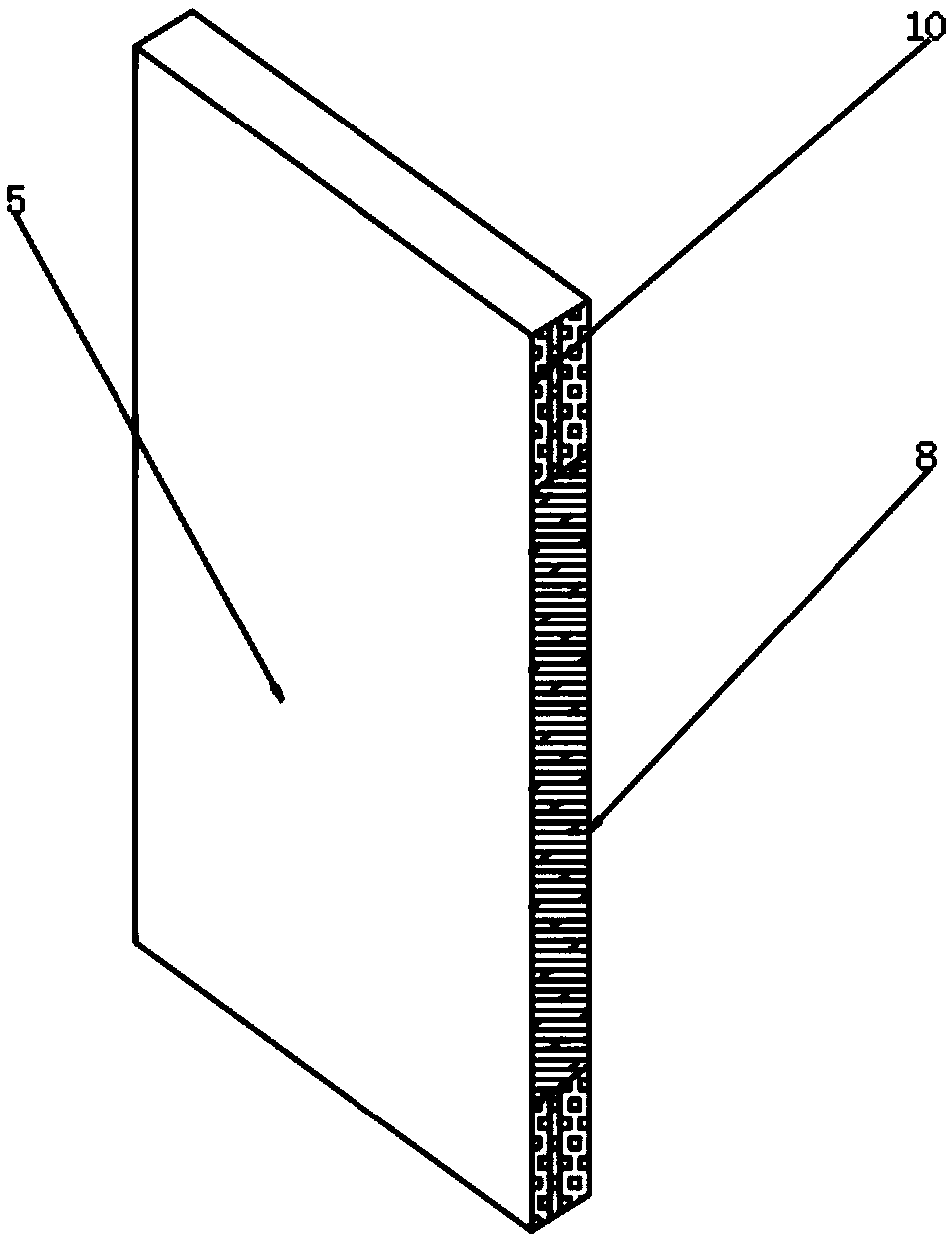

[0024] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a transformer with high heat dissipation, including a transformer body 1, a bottom plate 2, a transformer casing 3, a roller 4, a frame door 5, a frame 6, a fitting groove 7, a sealing strip 8, a positive Sexual magnet 9, negative magnet 10, heat dissipation fan chamber 11, heat dissipation fan 12, ventilation pipe 13, filter screen 14, baffle plate 15, condensation pipe 16, cooling hole 17, damping plate 18, damping spring 19, telescopic guide Column 20 and fixed end seat 21, bottom plate 2 is installed under the transformer body 1, transformer casing 3 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com