Ultralow-temperature resistant lithium battery electrolyte

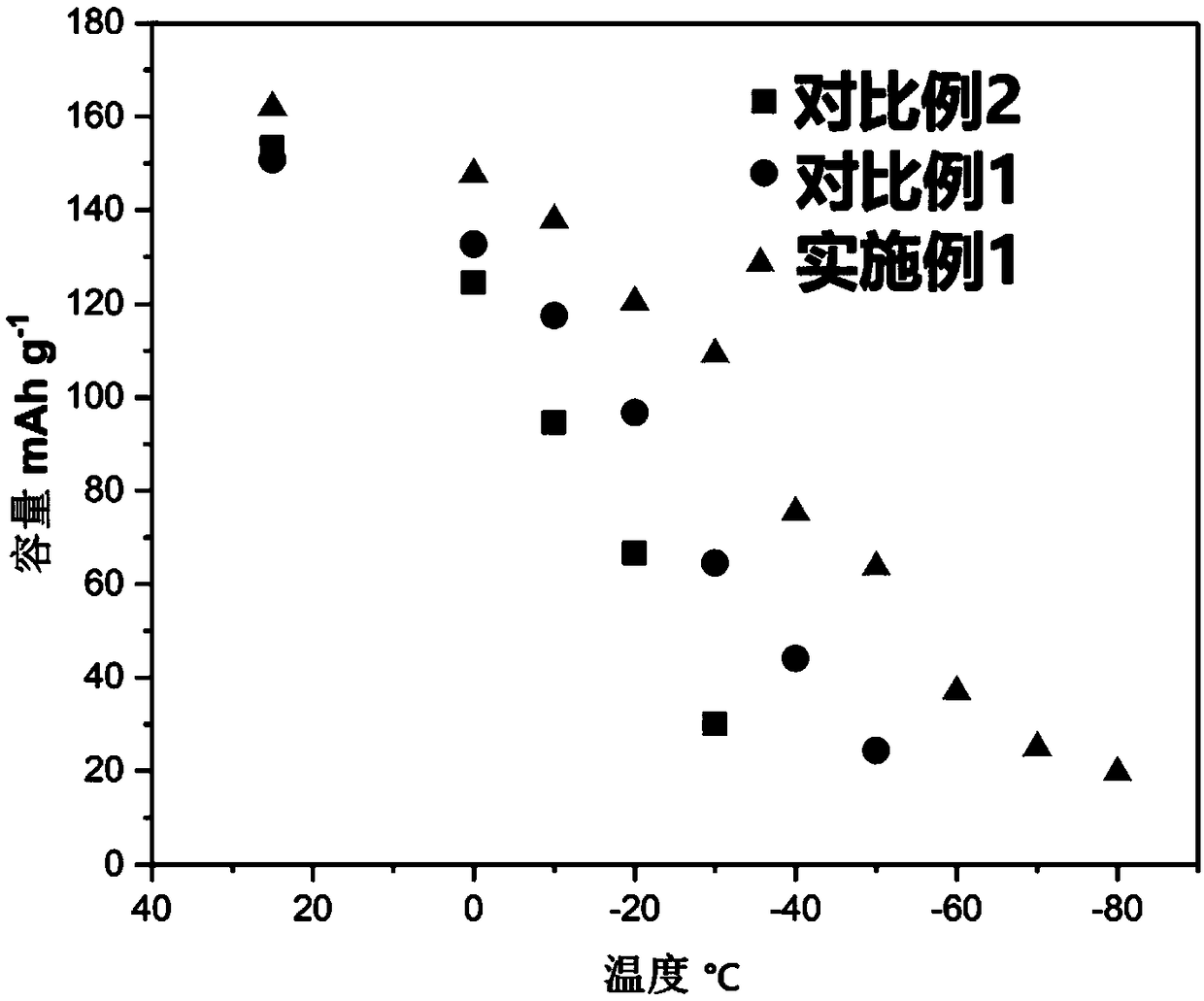

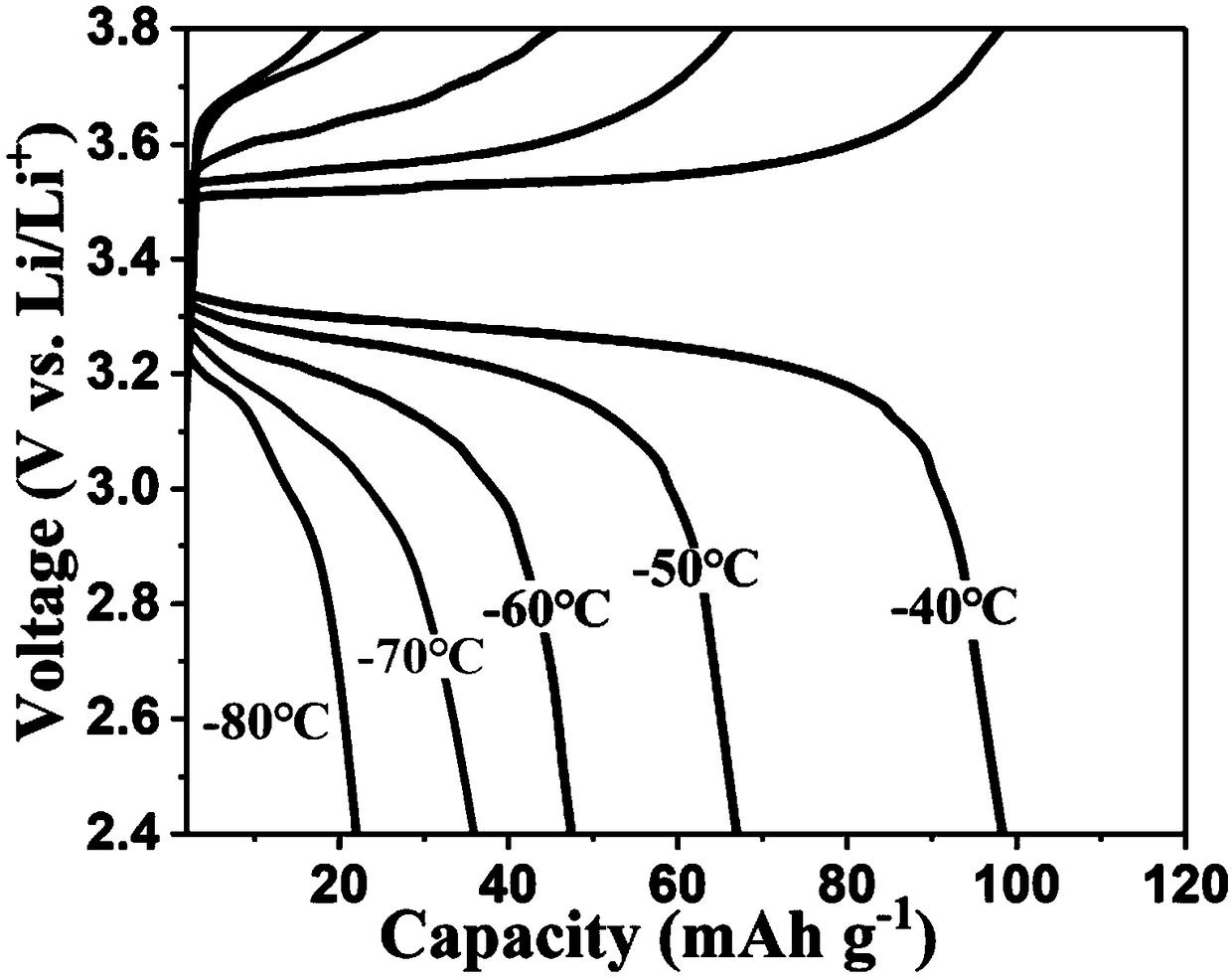

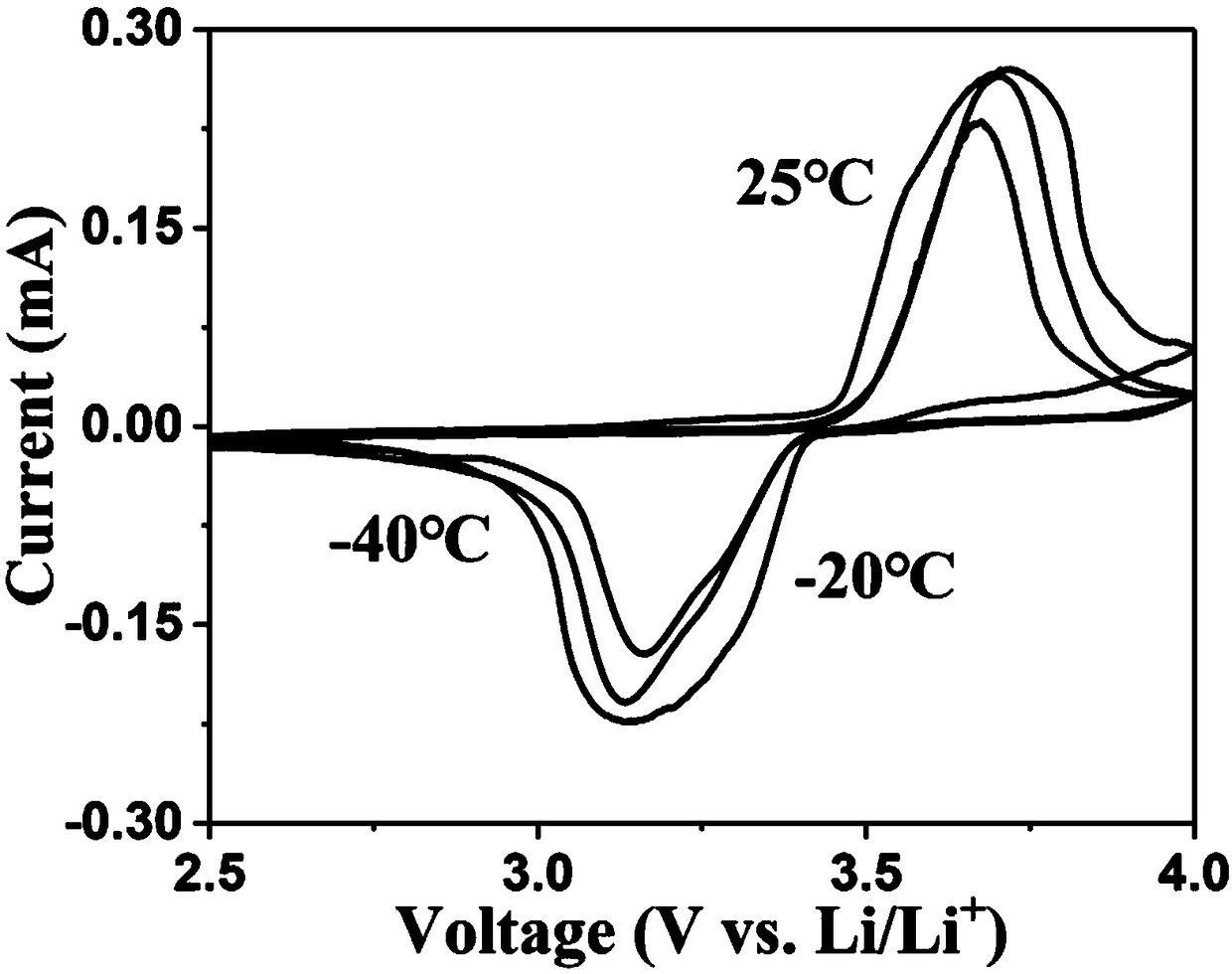

A lithium battery, electrolyte technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of capacity decay, high resistance, unusability, etc., achieve freezing point reduction, high conductivity, improve cycle performance and The effect of safety features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides an electrolyte solution for ultra-low temperature resistant lithium batteries, the composition and method of which are as follows: In a glove box, take 287g lithium bistrifluoromethanesulfonimide, 500ml ethylene glycol dimethyl ether, 500ml 1,3 Oxolane and 15g of potassium bromide are thoroughly mixed and stirred for 2 to 3 days to obtain a uniform solution.

Embodiment 2

[0025] This embodiment provides an electrolyte solution for ultra-low temperature resistant lithium batteries, the composition and method of which are as follows: In a glove box, take 287g lithium bistrifluoromethanesulfonimide, 500ml ethylene glycol dimethyl ether, 500ml 1,3 Oxolane and 15 g of sodium bis(trifluoromethylsulfonyl)imide are thoroughly mixed and stirred for 2 to 3 days to obtain a uniform solution.

Embodiment 3

[0027] This embodiment provides an electrolyte solution for ultra-low temperature resistant lithium batteries, the composition and method of which are as follows: In a glove box, take 287g lithium bistrifluoromethanesulfonimide, 500ml ethylene glycol dimethyl ether, 500ml 1,3 Oxolane and 15 g of sodium bis(trifluoromethylsulfonyl)imide potassium imide are thoroughly mixed, and stirred for 2 to 3 days to obtain a uniform solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com