Automatic perforating device for automobile hub

A technology of punching device and automobile wheel hub, which is applied in positioning device, boring/drilling, drilling/drilling equipment, etc. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

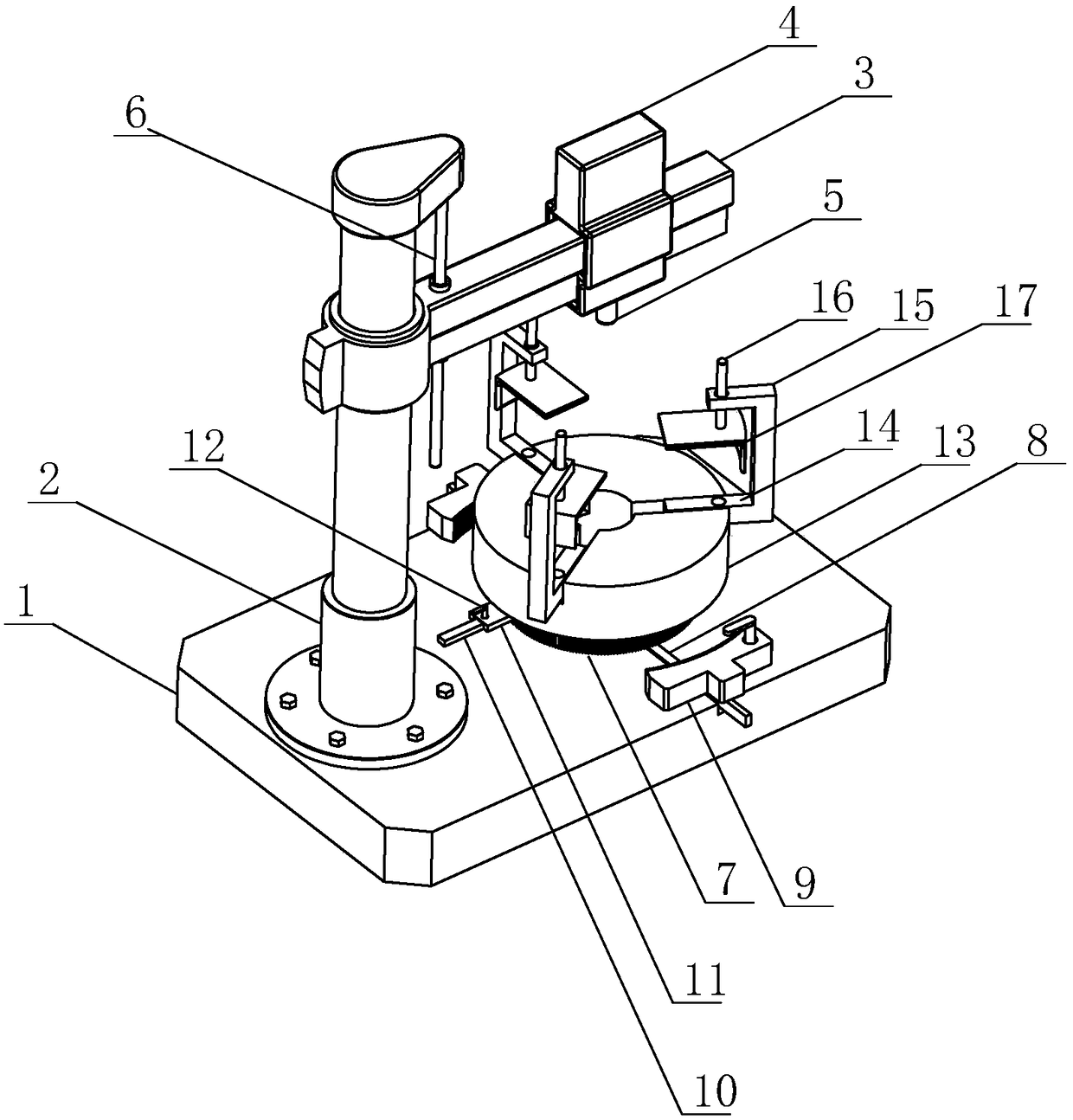

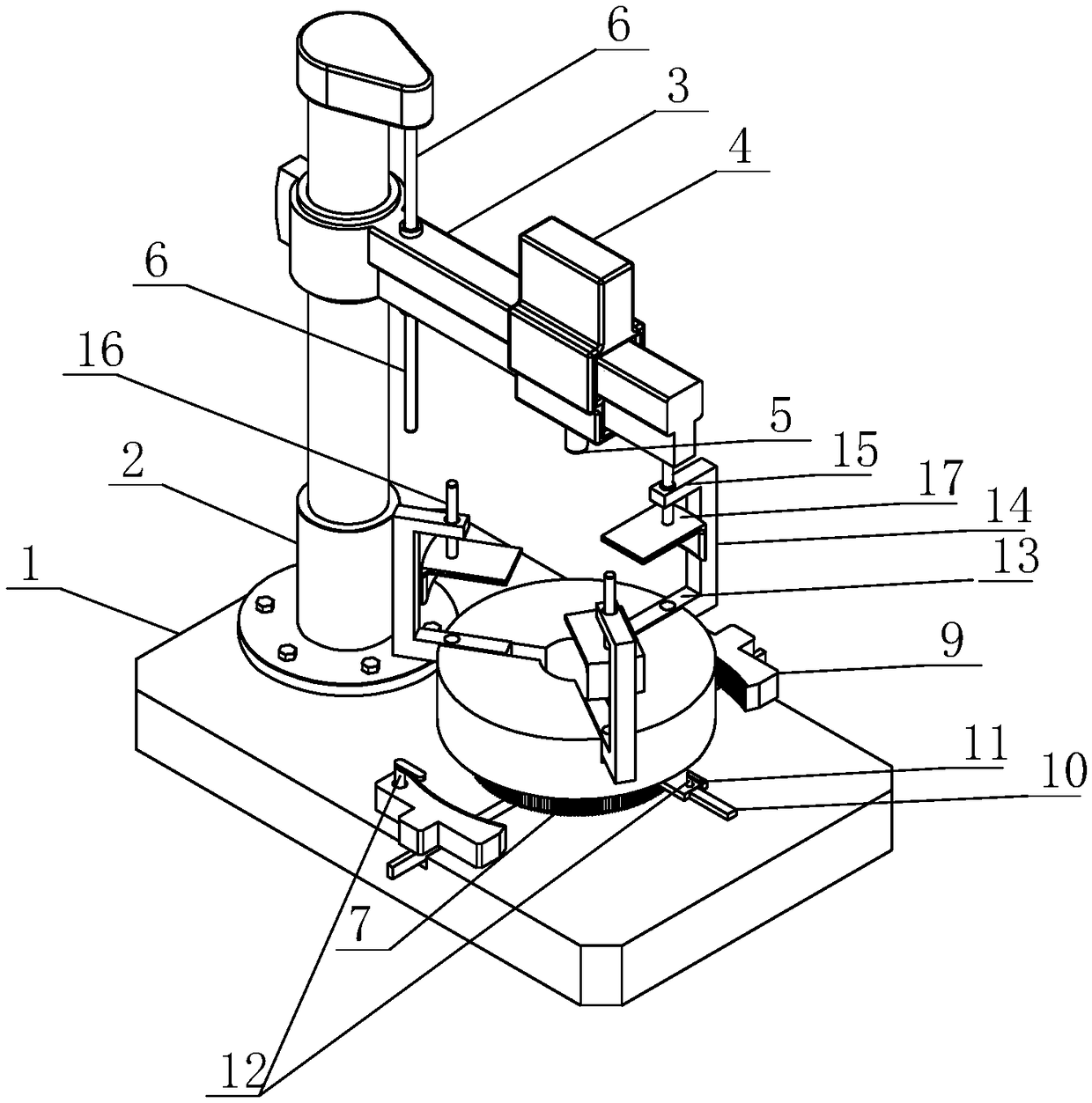

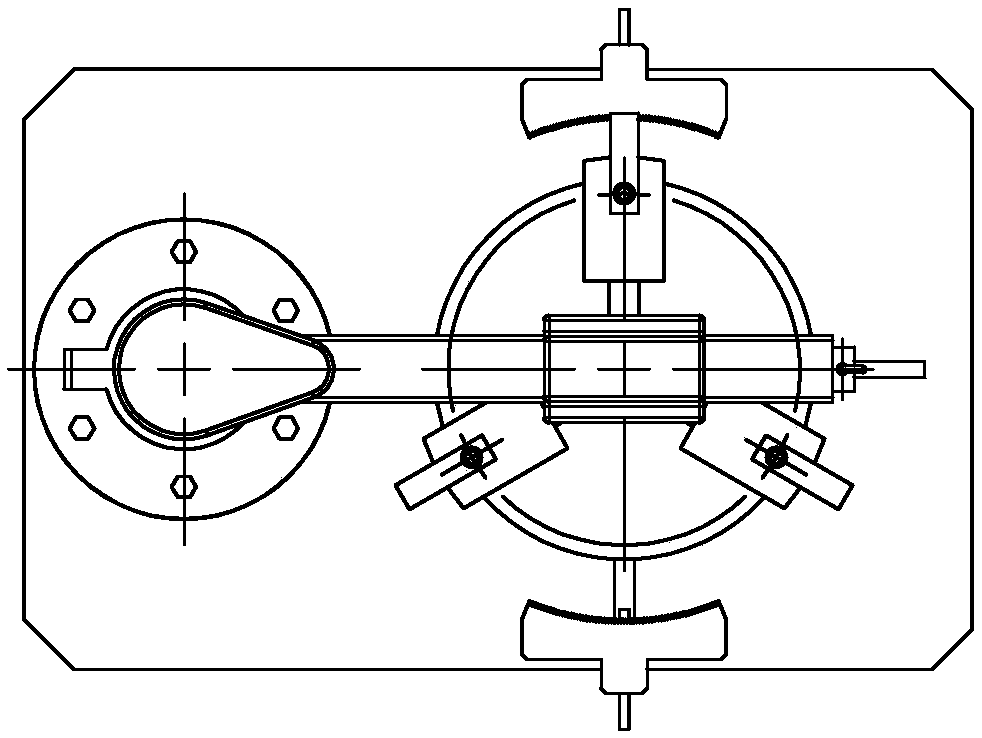

[0026] Embodiment 1: An automatic punching device for an automobile wheel hub, which is mainly used for punching holes when the automobile wheel hub is installed and refitted.

[0027] The specific structure includes base assembly, drilling rig assembly, fixture tooling assembly;

[0028] The base assembly includes a base platform 1, one end of the base platform 1 is used for fixing and installing the drilling rig assembly, and the middle part of the base platform 1 is biased away from the position of the drilling rig assembly for setting the fixture assembly, the The drilling rig assembly includes a drilling rig base 2, a drilling rig support arm 3, a drilling rig head 4, and a connector 5. The drilling rig base 2 is used to be installed and fixed on one end edge of the base platform 1, and is fixed by a flange.

[0029] The top of the drilling rig base 2 is a support column structure, and a lifting motor is installed on the top, and one side of the drilling rig base 2 is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com