Vibration-proof universal rotary machining device with function of tool feeding in inclined direction

A rotary processing and anti-vibration technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of limited processing travel of the milling head, affecting the machining accuracy of milling and drilling, and difficult to disassemble and assemble the milling head, and achieve simplification. The operation of moving the feed, avoiding easy vibration and loosening, and the effect of stable moving stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

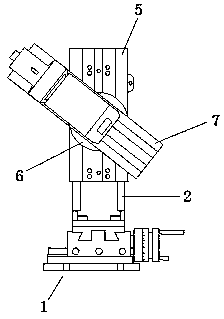

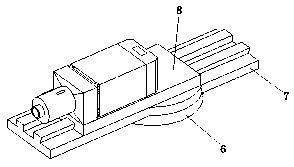

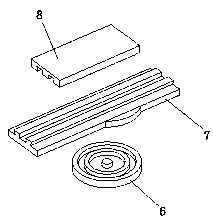

[0029] Example. Anti-vibration oblique feed universal rotary processing device, such as Figure 1 to Figure 7 As shown, a base 1 is included, and a column 2 is arranged above the base 1, and the base 1 and the column 2 are connected through an anti-vibration device. The frame plate 4, the fixed seat 3 is connected with the fixed frame plate 4; the side of the column 2 is provided with a slider 5, and the slider 5 is provided with an oblique feed positioning device, and the oblique feed positioning device includes a positioning device Chassis 6 and the guiding device that is connected with positioning installation chassis 6; Described guiding device comprises the rotary guide plate 7 that is located at the top of positioning installation chassis 6, and rotary guide plate 7 is provided with feeding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com