Air pressure type grouter

A kind of grouting machine and air pressure technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems of poor shockproof effect, uneven cement mortar, affecting the normal use of grouting machine, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

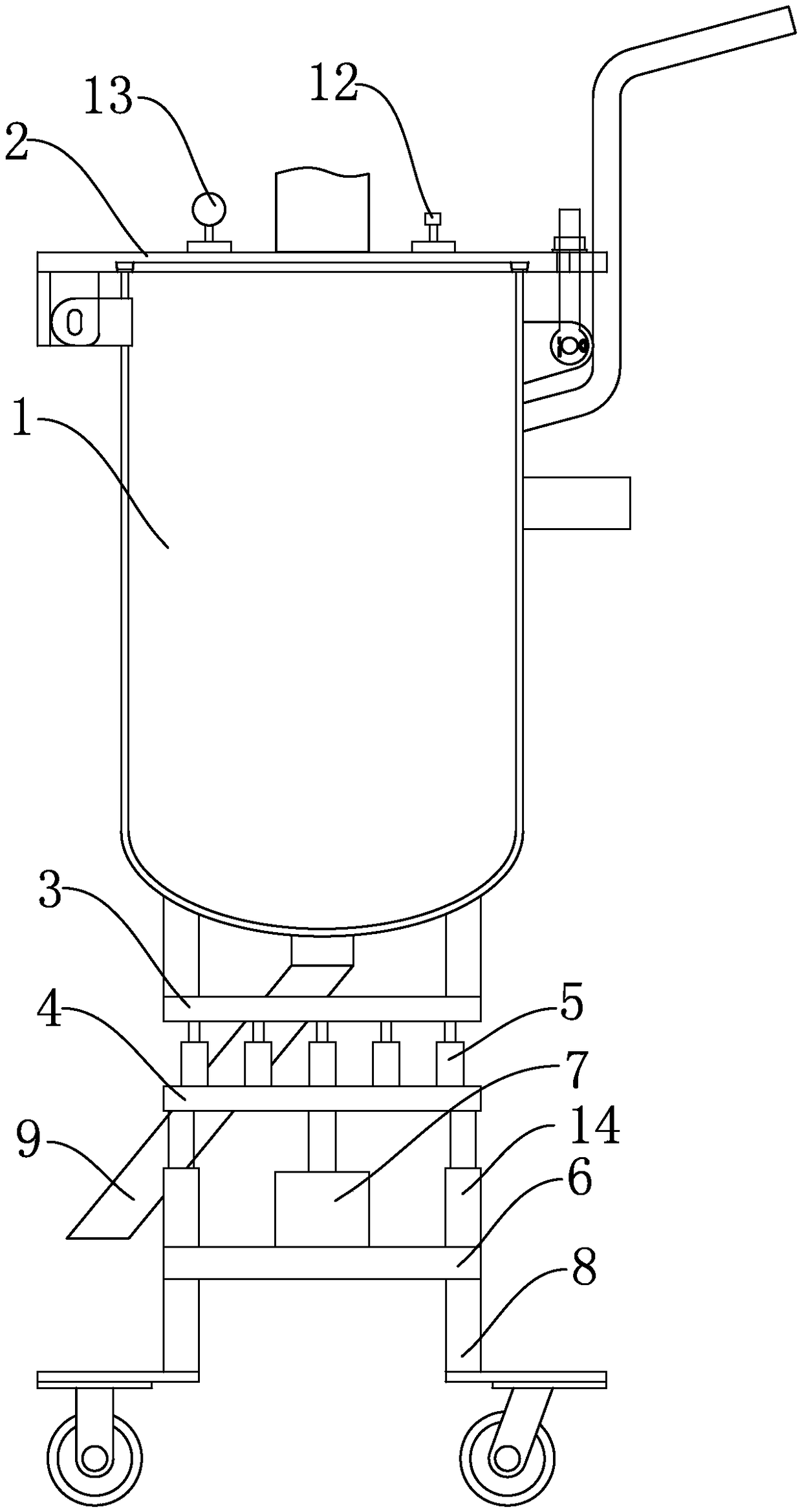

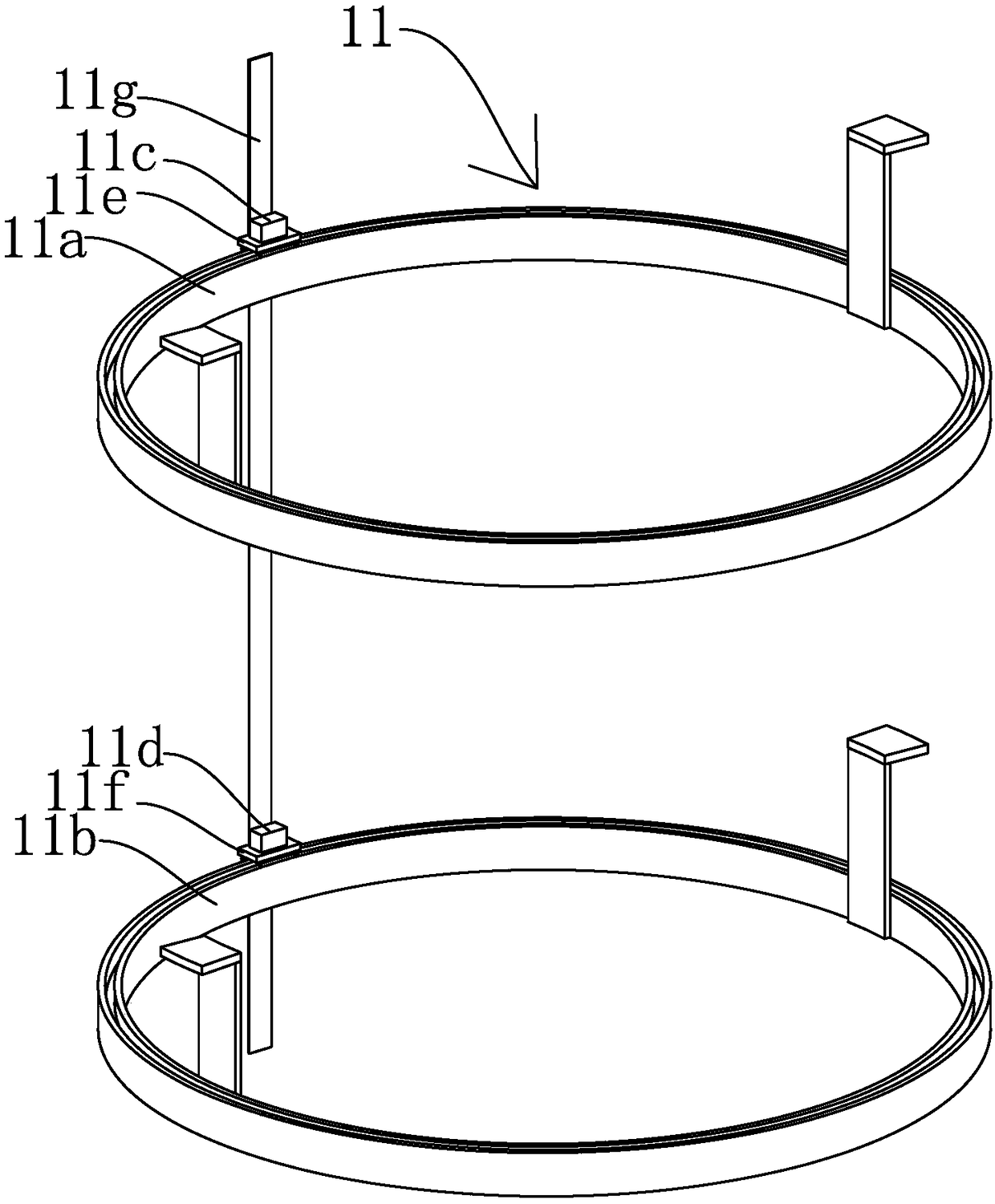

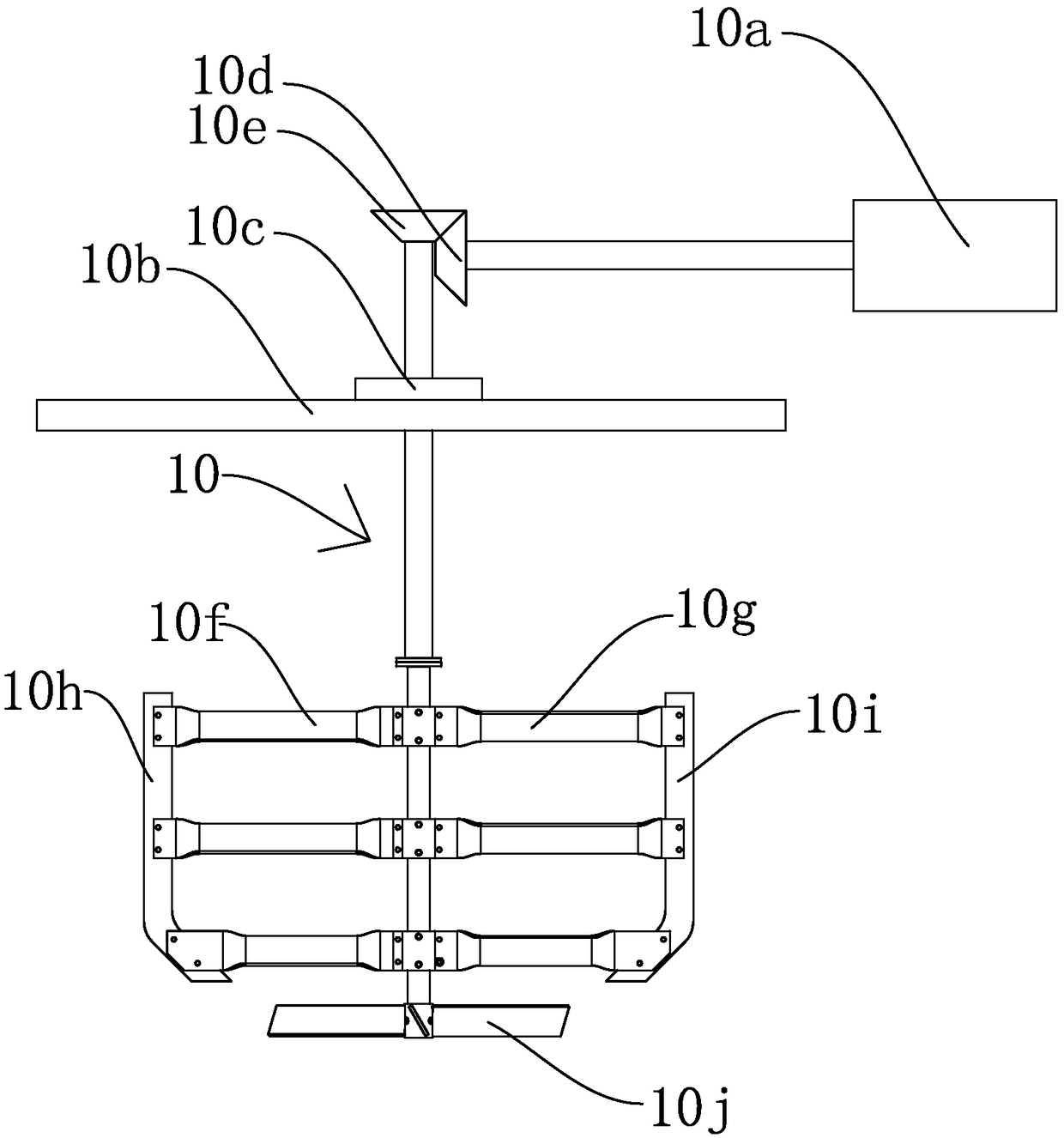

[0022] like Figure 1-3 As shown, a pneumatic grouting machine includes a tank body 1 and an end cover 2. A mounting plate 1 3 and a mounting plate two 4 are fixed under the tank body 1. The mounting plate 1 3 and the mounting plate 2 4 are arranged in parallel up and down, and the mounting plate A number of buffers 5 are arranged between the first 3 and the second mounting plate 4. The buffer 5 has the function of shock absorption. A mounting plate 3 6 is also arranged under the second mounting plate 4, and a hydraulic cylinder 7 is fixed on the third mounting plate 6. The cylinder 7 has the function of lifting and lowering. The piston rod of the hydraulic cylinder 7 is arranged vertically upward and the end is fixed with the mounting plate 2 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com