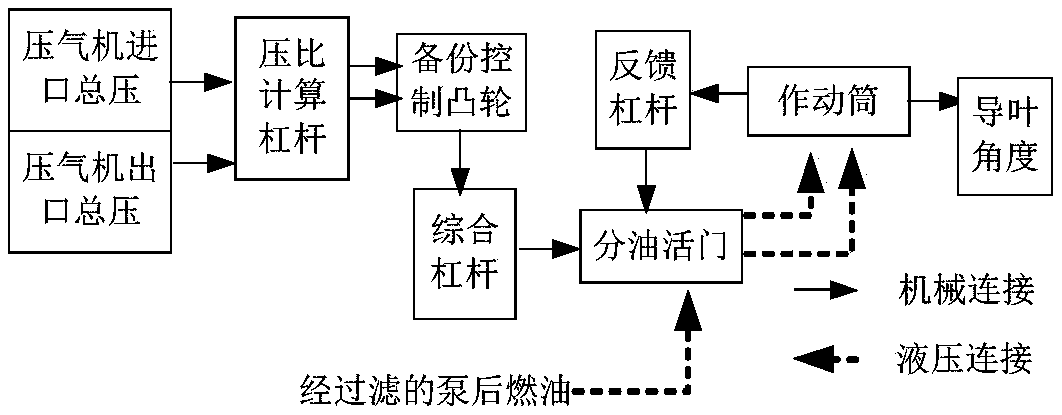

Guide blade regulator for pressure ratio control of gas compressor

A technology of pressure ratio and compressor, which is applied in the direction of engine control, pump control, machine/engine, etc., can solve the problems of complex regulator structure and high strength requirements of parts, solve the problem of input parameter conversion, ensure stable work, and increase performance The effect of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

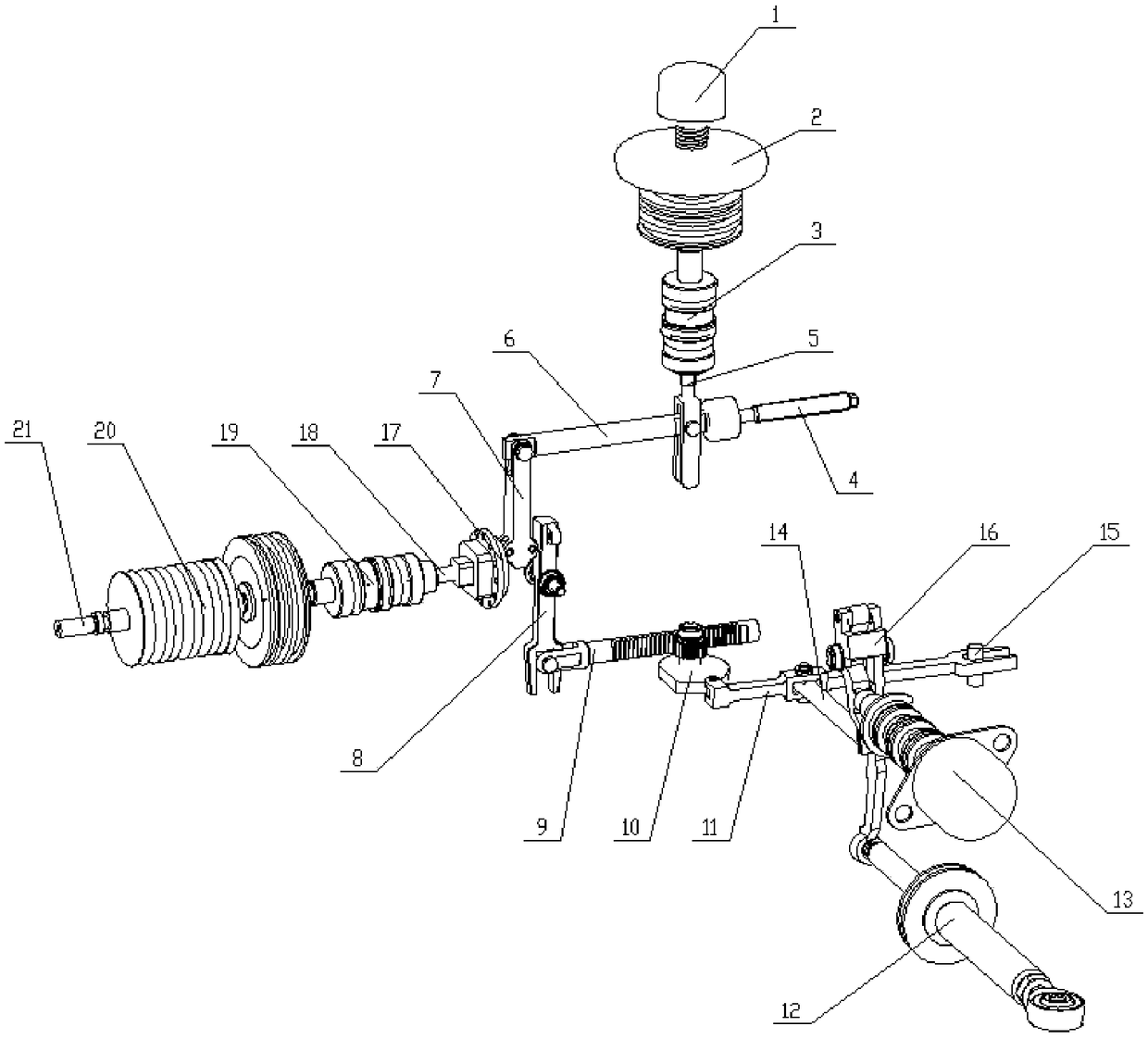

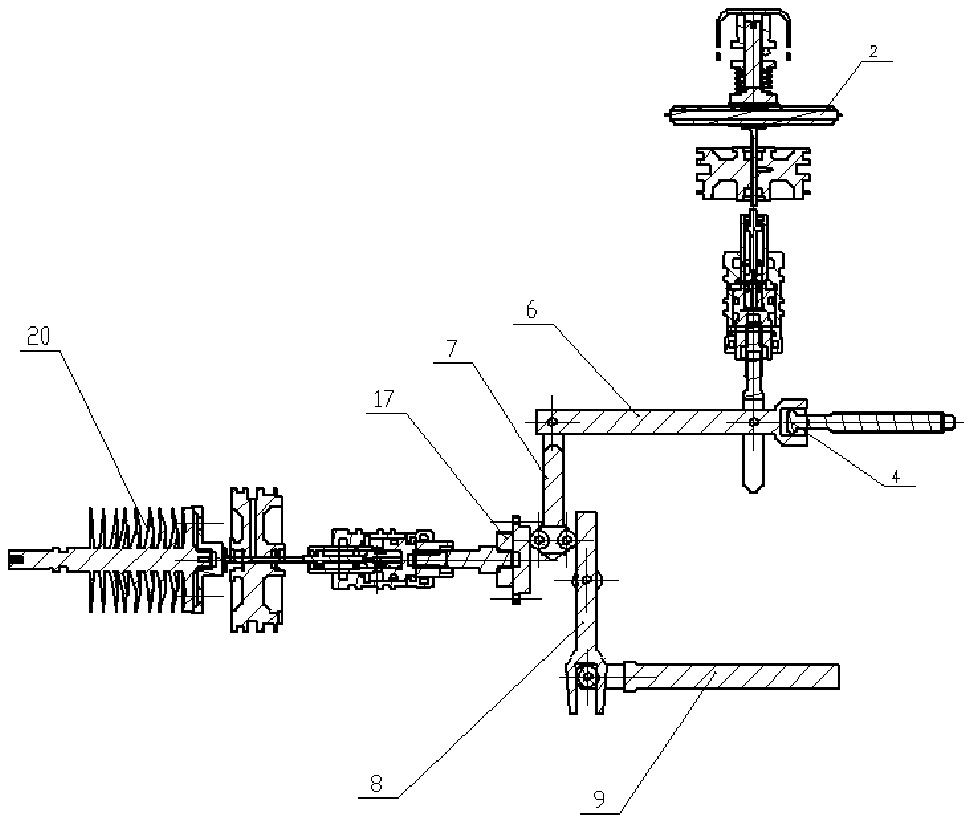

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

[0022] Such as figure 2 As shown, a guide vane regulator for compressor pressure ratio control is characterized in that it includes a P3 bellows, a P1 bellows, a pressure ratio lever 8, a rack 9, a cam 10, a comprehensive lever 11, 15 fulcrums, a slider 7. Executing mechanism; the P1 diaphragm box is hinged with the slider 7, and the two sides of the slider 7 are respectively attached to the P3 diaphragm case and the pressure ratio lever 8. The lever 8 is movably connected with the rack 9, and the rack 9 and the cam 10 are meshed through the gear. Cam 10 is close to one end of integrated lever 11, and fulcrum 15 is contained in the shift fork of the other end of integrated lever 11, and integrated lever 11 is hinged with actuator.

[0023] A lever 6 and an adjustment nail b4 are added between the P1 capsule and the slide block 7, the P1 capsule and the lever 6 are hinged, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com