Robot constant-force polishing method

A robot and constant force technology, applied in grinding/polishing equipment, parts of grinding machine tools, manufacturing tools, etc., can solve the problems of robot scratches, poor surface consistency, etc., to reduce human errors, improve the quality of polished surfaces and Accuracy, the effect of reducing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

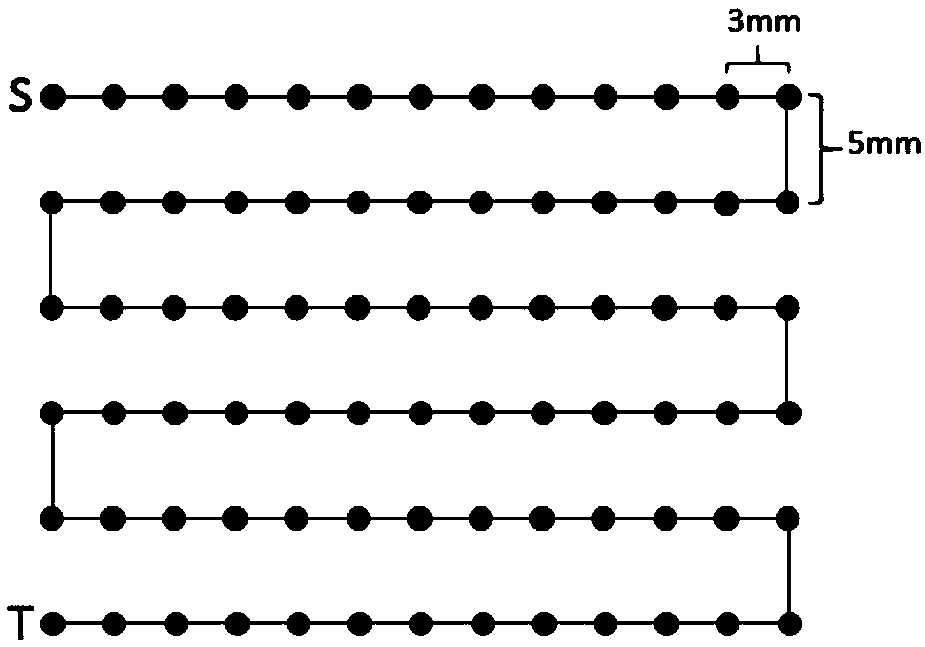

[0036] Example 1: Robot constant force polishing method for flat surfaces

[0037] Step 1: Obtain the equation g(x, y, z) of the processed surface of the workpiece, such as figure 1 The plane equation shown is g(x,y,z) where (0<=x<=36, y=0,0<=z<=25), y is the direction perpendicular to the paper surface, z is the paper The up-down direction of the plane, x is the left-right direction of the paper plane;

[0038] Step 2: Set the start and end points of the processing range as S(0,0,25), T(0,0,0);

[0039] Step 3: Generate a reference point G on the i-th row and j-column on the processing surface g(x, y, z) in a row-scanning manner with a row spacing of D=5mm and a column spacing of L=3mm ij (X ij ,Y ij ,Z ij );

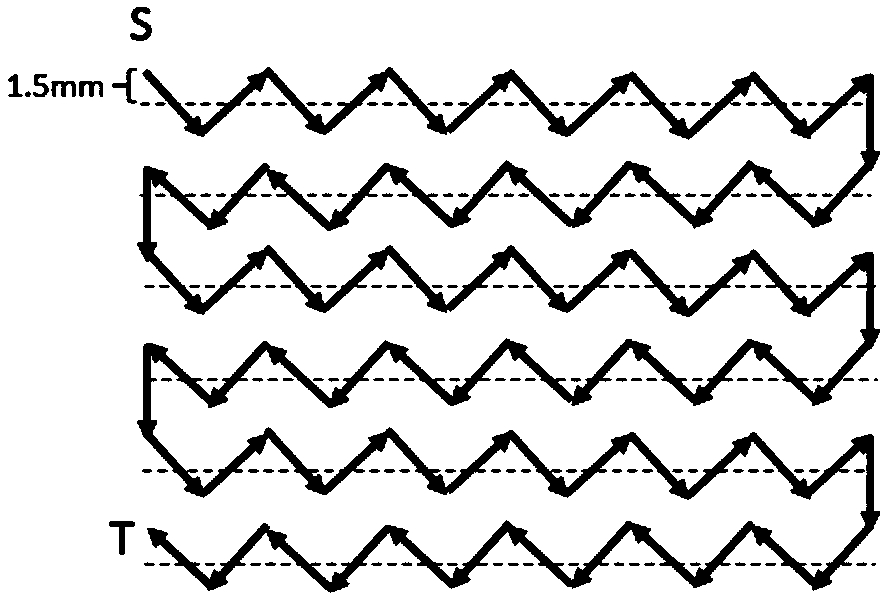

[0040] Step 4: Set the offset range △G(0,0,±1.5), offset the reference point of the workpiece surface to be processed to obtain the path control point S k =G ij +△G i , k=(i-1)+j, k is the ordinal number of the path control point, in the adjacent path control ...

example 2

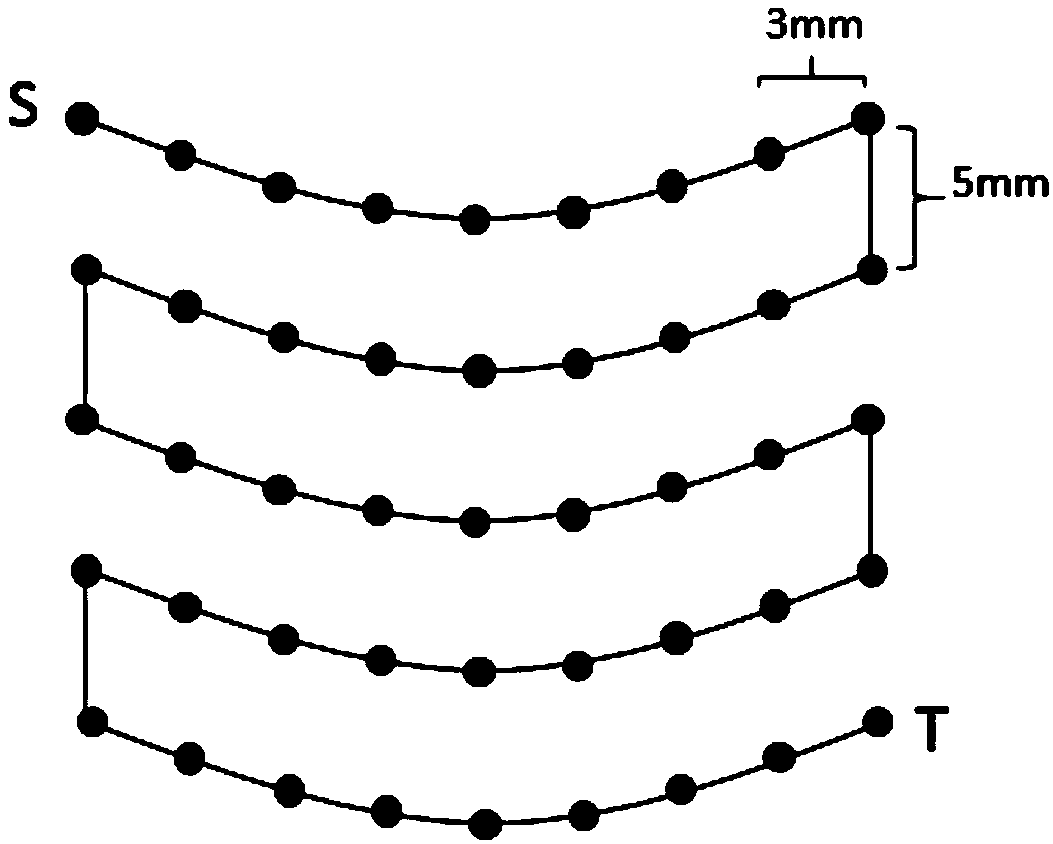

[0043] Example 2: Robot constant force polishing method for curved surfaces

[0044] Step 1: Obtain the equation g(x, y, z) of the processed surface of the workpiece, such as image 3 The plane equation of the arc shown is g(x, y, z) where (x2+y2=122,,0<=z<=25);

[0045] Step 2: Set the start and end points of the processing range as S(-12,0,20), T(12,0,0);

[0046]Step 3: Generate a reference point G on the i-th row and j-column on the processing surface g(x, y, z) in a row-scanning manner with a row spacing of D=5mm and a column spacing of L=3mm ij (X ij ,Y ij ,Z ij );

[0047] Step 4: Set the offset range △G(0,0,±1), offset the reference point of the workpiece surface to be processed to obtain the path control point S k =G ij +△G i , k=(i-1)+j, k is the ordinal number of the path control point, in the adjacent path control point S k The interpolation algorithm is used to form the robot polishing trajectory, such as Figure 4 Polishing path shown;

[0048] Step 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com